It will have to have an extra pump behind the large main pump and a control valve and port on the side of the tank where the square cover plate is. Might be able to find these parts from some salvage yards.

Gary

Thanks Gary.

Does the tilt operate using the same lever as the up/down to the right of the seat?(moved left/right) I've tried getting a look at its operation from YouTube videos but can't get a clear shot. I'll inspect the tank when I get back to it to familiarize myself with the layout. Anybody got a schematic or some pics by chance?

Thanks, Zane

Basically you'd be looking for a 35Hxxxx Hydraulic Control (two valve) and piggy back pump. Tilt cylinder is an add on linkage to the blade control valve. System designation is a #173B Hydraulic Control

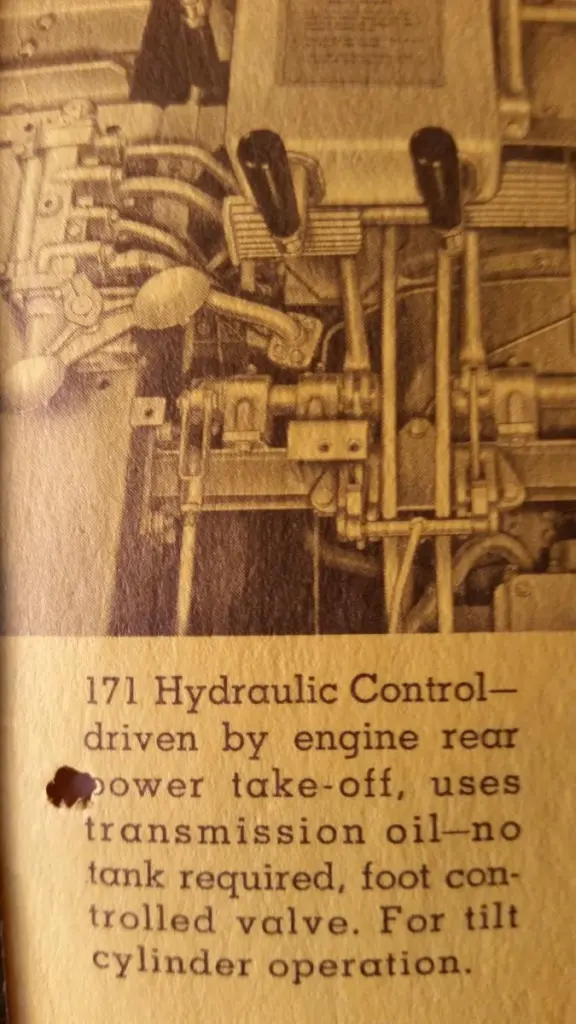

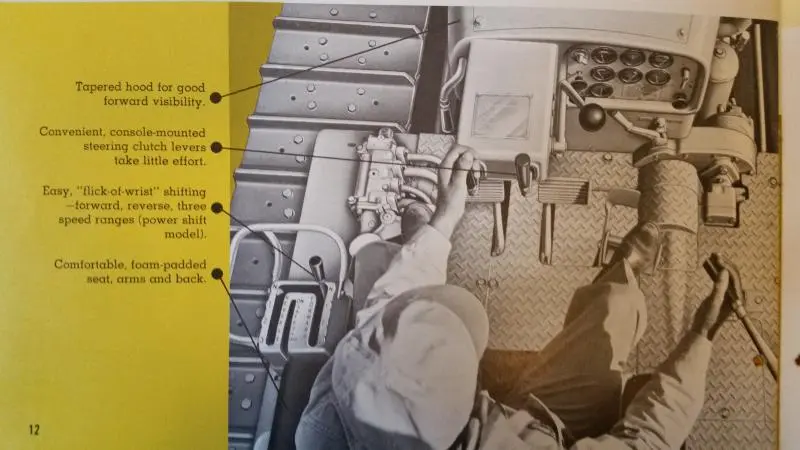

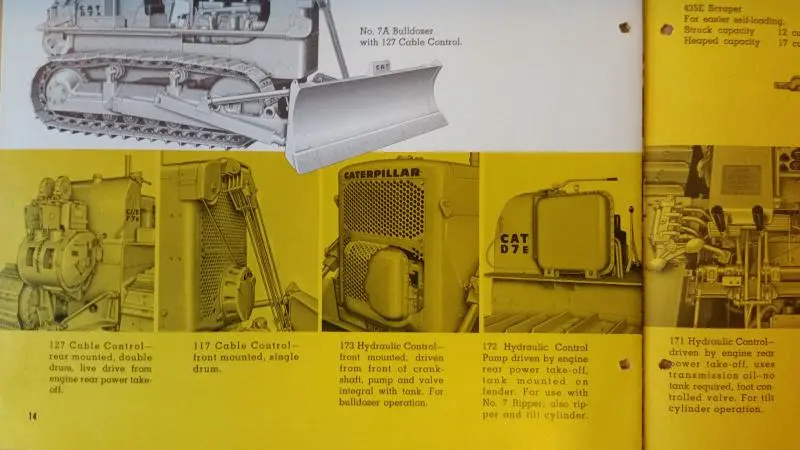

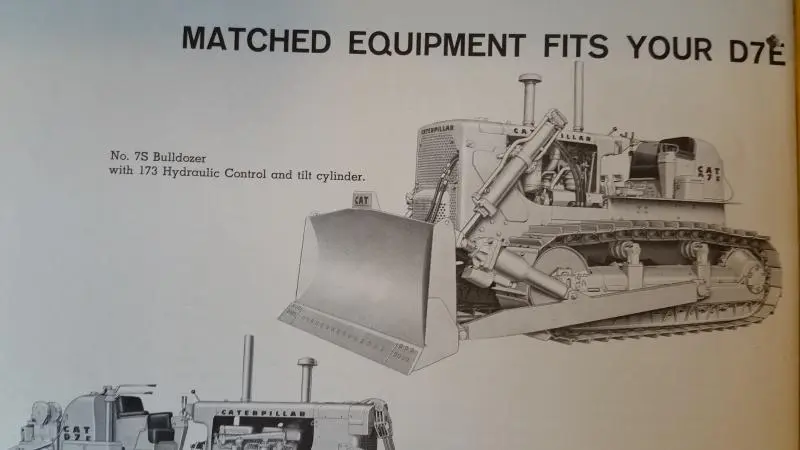

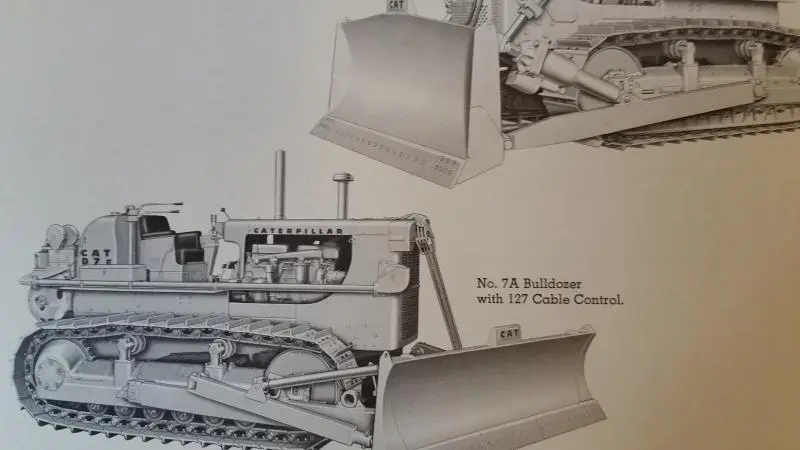

Hi Zane, Caterpillar also offered the 171 hydraulic control which used oil from the transmission to operate the tilt cylinder. The 171 was used to provide hydraulic tilt on cable controlled blade equipped tractors. If you could find one it could also be used in your application. The photos are from an original D7E sales brochure. The 173 hydraulic control had the front mounted tank and pump with the pump driven by the front of the crankshaft. The 172 hydraulic control had the tank mounted on the right fender and the pump mounted on the rear accessory drive at the rear of the engine. The D7E in my avatar is equipped with the 172 hydraulic control.

[attachment=30558]171-1.jpg[/attachment] [attachment=30559]171-2.jpg[/attachment]

Thanks,

Craig

Thanks OM and Craig.

That is wetty wetty interesting. I'll be working on the old girl this weekend and will explore what's there now. I ended up ordering parts too late in the week to get the heads back on her. But, there is plenty more that I can do..... like removing the rest of the pony accessories in preparation for the 50MT. I managed to get out for less than 200$ on the complete starter. Alternator bracket fab is next.

Thanks again. I'll let you know what I find.

Zane

The early D7E front hyd units were #46's like on the 17A's. Just diff serial #'s.

Yes ROME/KG, you are correct the early 173 was indeed a #46 unit as used on the D7D (17A series D7). Caterpillar offered a wide array of blade control options including both hydraulic lift systems and two cable control options.

[attachment=30571]D7E BLADE 1.jpg[/attachment] [attachment=30572]D7E BLADE 2.jpg[/attachment] [attachment=30573]D7E BLADE 3.jpg[/attachment]

The 173/#46 unit was later discontinued and the 172 became the new 173.

Alright guys, I finally got a chance to see another machine besides mine over the Christmas break. If anyone needs parts, Blount Equipment in Hoboken, Ga. sure has a lot. They're not exactly close to me but at least they're within driving distance. Here's my issue. I've been able to do some simple recon with a grand total of 1 trip to see these D7's(47A, 48A, 75E, and 92V machines). The 75E's looked the most promising. But, am I mega-lame to ask why I need a separate pump? I took some picks of the 75E's they had there but none are quite good enough to see that mysterious second pump. Adding a pump to the build will definitely drive up the cost. However, the rectangular plate on the hydro tank looks like it would just bolt right in. To make things worse, I'm having a hard time mustering the will to keep buying Jensales manuals. I know they gotta make money on the literature but damn! It seems like every system on this machine has a different manual. I've already got 4 different ones! A D7F manual that I downloaded from Liberator Manuals shows the main pump with the option of supplying the ripper. If it'll run a ripper, why wouldn't it run tilt?

Thanks for all of the help, Zane

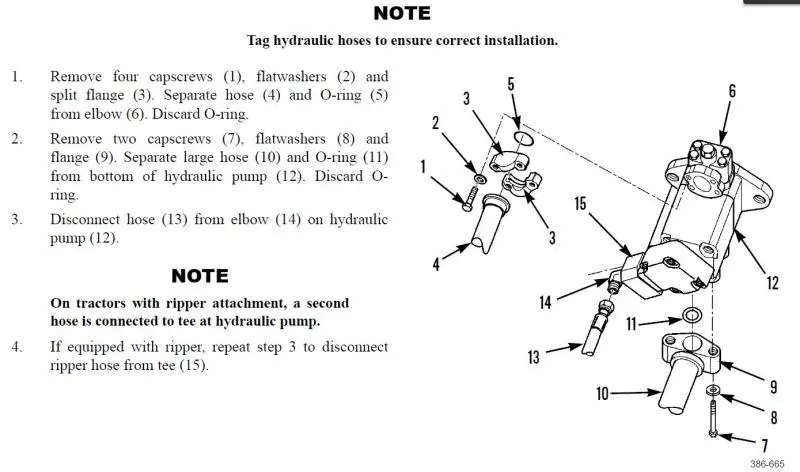

[attachment=32923]RipperHoseOffOfMainPump.jpg[/attachment]

[attachment=32924]75E_TiltControlValveAssembly.jpg[/attachment][attachment=32925]BlountEquipment.jpg[/attachment]

The 173B Hydraulic System in the 75E picture uses a two section pump.

The blade lift cylinders and ripper run off the 54 gpm (large) pump section and the tilt cylinder runs of the 16 gpm (small) section. When the tilt section is not being used flow is combined with the large section available to blade lift and ripper cylinders. The issue would be tilt control running off the large pump section.