I have done this once on a D8 engine about 20 years ago. I had a lot pressure on it with a similar puller to the one in your photo. It would not come off. I put a cutting torch on a pole because I was not brave enough to do it hand held. I heated it up still would not come off. I took a break to consider my options. About 1/2 hour after I heated it, it came off with a bang. It literally flew through the air. As it cooled it decided it was time to release.

The Cat manuals are a good starting point but they are under the assumption that everything is relatively new and not forty or more years old.

When heating the pulley always add head to the outer section as well. I have seen these crack or even explode when the center is heated but not the outside. An ex fitter at work broke his foot when he heated a large pump impeller incorrectly and it exploded and part of it landed on his foot.

Sometimes if you heat the pulley and put tension on the puller and hit the center bolt squarely with a 4lb hammer the shock will cause the pulley to come off.

Also how much heat did you put into it? A heat gun for temperature monitoring is the best as you can go up to around 100 degrees Celsius or 212 degrees Fahrenheit without damaging anything as long as you heat it evenly. I've seen a lot of people think they are heating it up but only really warmed it up. Doesn't take much heat to burn the paint like you have in the pictures.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

as phil says be careful with heat. done wrong you can make it lock on worse.

penetrating oil and time is your best friend. you can use a standard hydraulic bearing puller. just remember be gentle apply small amount of force in small bites some time they need time and a few love taps with a dead blow hammer to break free. its real easy to over do something and break it. if it wont come walk away leave the puller on it and go have lunch.

if you using a gas axe get a proper heating barrel (rosebud) for it not welding tips they are too concentrated. and yes a non contact thermometer is a very good idea. and keep the torch moving so you heat evenly.

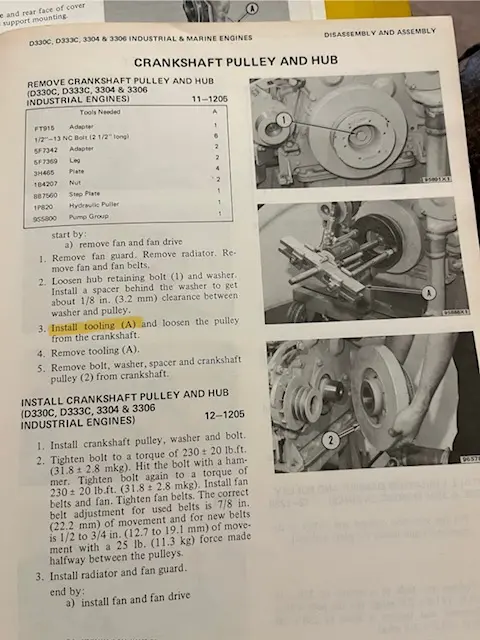

Have you considered renting a hydraulic puller if you'd prefer not to buy one? Screw pullers aren't nearly as effective as hydraulic pullers in my opinion, and if Cat's suggesting that's what should be used, that's a big clue on what should be done : ) Not absolutely necessary, to answer your question, but having the right tools makes the job much easier - not just this job but any job