The steering box on these loaders looks like it's just sitting there waiting for a good tap with a block of wood and a big hammer to loosen it up..............All I can say is looks are deceiving! 😆

Couldn't get up with the guy with the 16# sledge hammer, so we rigged up this big whammer with one of the smaller counterweights off the spare parts machine frame. Even with that and a torch heating each side of the frame, the steering box quill ended up mushroomed on the end and we cut the frame out to release it. Hated to do it, but it had to come out!

This loader was partially disassembled and engine/trans and rear axle put in the shed before we got it. it appears to have much less wear on pedals, forward/N/reverse lever pivots etc than the one we have been running. So it's a parts machine and we're glad to have it. Especially after finding that the follower we needed was $500 from CAT. Unfortunately the steering wheel was open to the weather on this one too and though the follower was in good shape, the steering valve actuator below it was in worse shape than the one from the running machine. So no good springs in it. Springs are ~$20 each (3 required) and ~$5 each (3 required). Also discovered that the nut on the bottom of the steering shaft which retains the steering assist actuator assembly was stripped and laying in the bottom of the housing. Probably why it became a parts machine instead of being the runner!

Not wanting to go through this process with the "good" box, we looked at swapping the complete lever shaft with follower, but it will not clear the housing even if the hydraulic filter is removed, so that won't work. So we decided to swap just the follower. It was tedious and took a couple trys to get it right, but we did it in the end. The tedious part is the fact that this is a double timken roller bearing assembly with loose rollers (no cages). The picture is of the type that failed, the rollers run directly on the hardened follower shaft and there is a hard washer under the retaining nut and lock plate that keeps the rollers in. The type we installed has a normal race on the end next to the retaining nut, so putting in the rollers wasn't quite as easy as the other type would have been, but we were able to stick them all to the race with grease and install it without dropping any. Actually got it all together the first time and then discovered a roller had fallen into the space between the inner rollers and the outer rollers and had to remove the back race fish the rollers all out and stick one in the front where it was needed and then reinstall.

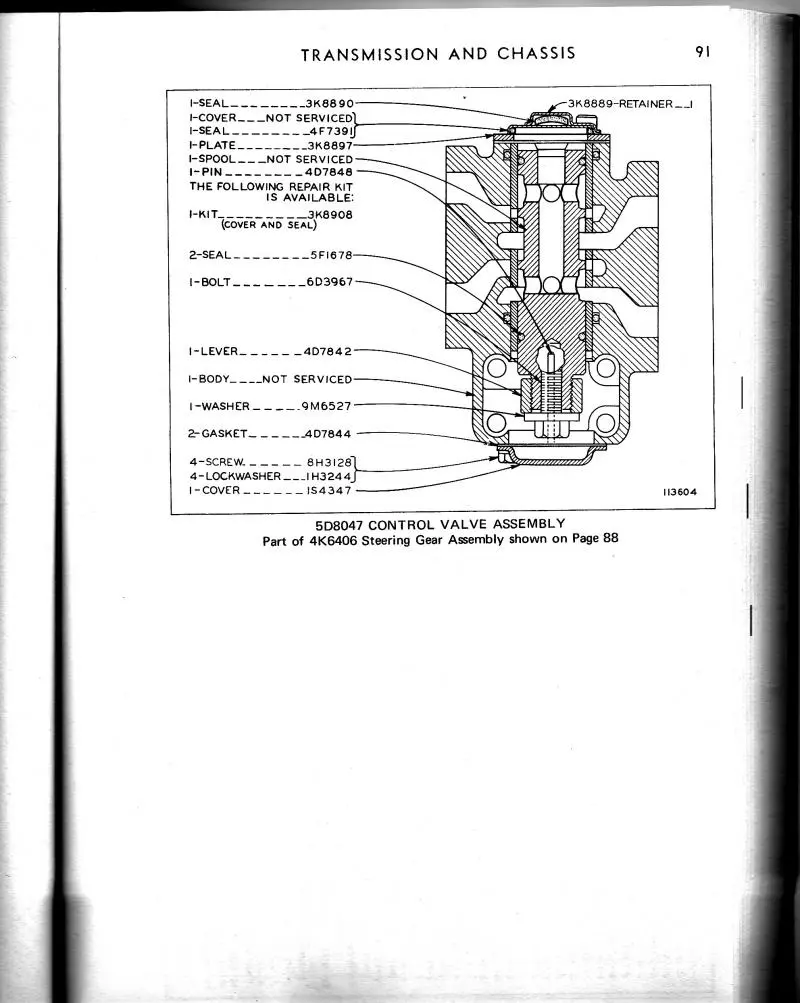

So the gear box is now closed back up, and we're waiting on the springs to come from CAT before we can reinstall the steering assist valve. I really need a diagram showing the order of assembly for these parts! The local CAT dealer (60 miles away) only has it on microfiche and has no way to print of fax me a diagram. I may have to go by and take a picture of his viewer screen unless someone has a parts book I can get a scan from.

.webp)

D2-5J's, D6-9U's, D318 and D333 power units, 12E-99E grader, 922B & 944A wheel loaders, D330C generator set, DW20 water tanker and a bunch of Jersey cows to take care of in my spare time😄

.webp)