Hi Jimer,

doing some research in some grey Caterpillar Operation and Maintenance Instructions books I find it said that 250 deg. F is the maximum safe operating Temperature limit for the trans oil. This should be at the RED Range on a correctly calibrated Trans Temp Gauge.

Any anticipated continued use above this temp a lower gear should be selected or lighten the load.

--in another publication on using a hydraulic retarder in a scraper tractor it says to not let the retarder temp exceed 275 deg. F. To my way of thinking this would be an absolute short time limit or the oil would deteriorate.

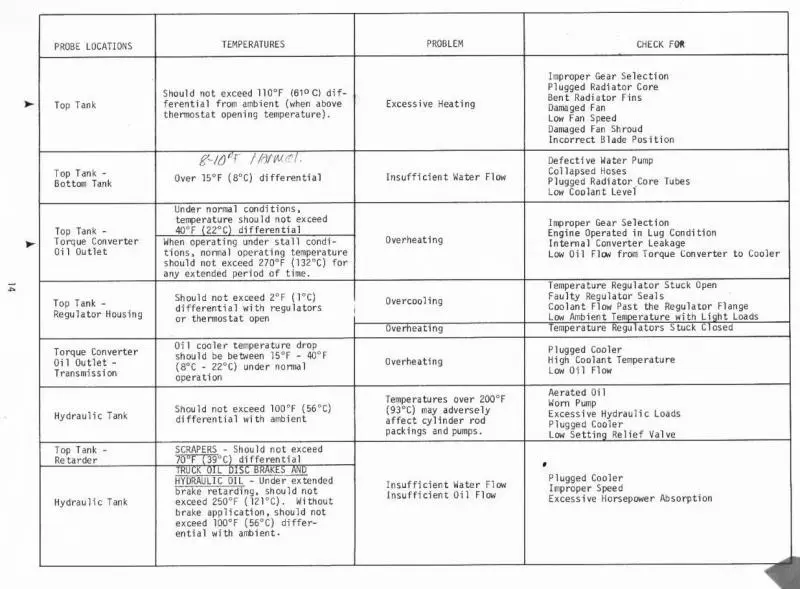

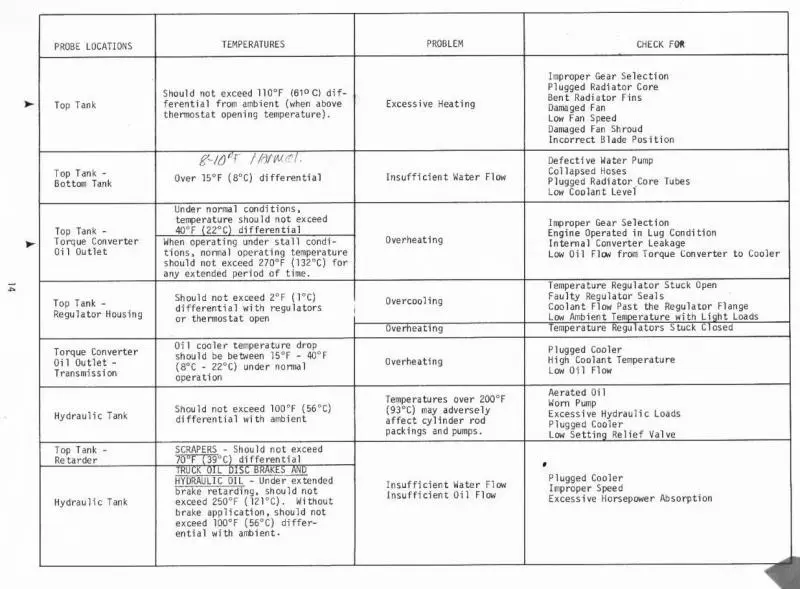

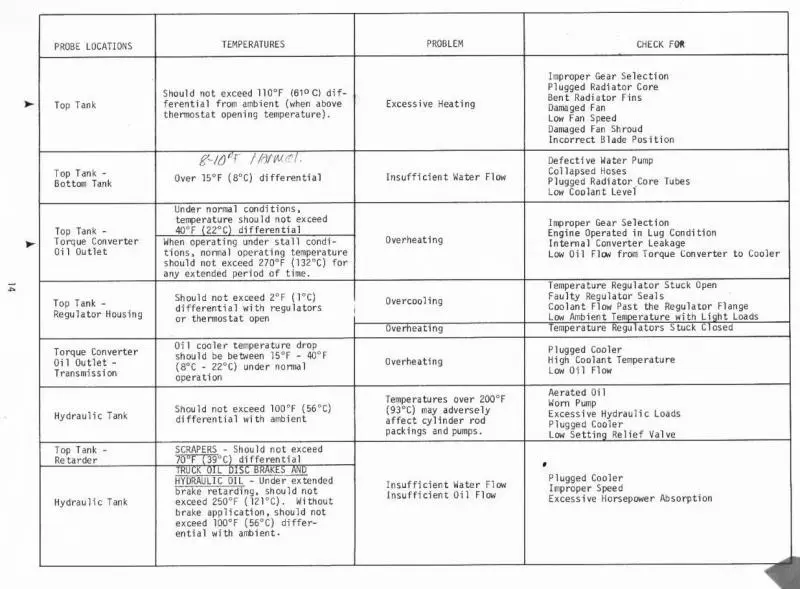

Chart below should give some indication of test figures for Troubleshooting a cooling system.

Cool down is I feel is best achieved at around half+ engine speed--more oil and air flow.

If your unit is fitted with a problematic air to oil TC oil cooler that clogged their fins easily in land clearing from dust, grass and leaf trash.

If in dusty conditions and some one hosed out the cooler and started operating again before the water had dried completely the dust/mud would solidify and be very difficult to remove short of removing the core and soaking etc.

We had a big problem with these in early days as owners ordered machines with rock guards and operated them in mud/clay. This would build up around the rollers and cause big drag that slowed the machine, robbed power and caused T/C overheating.

Overnight the mud in the rock guards would dry somewhat and stick in place causing drag forever more.

Removing the rock guards and cleaning out the spaces above the rollers and track frame alleviated the drag and overheat problem.

You seem to have good in spec. cooling for the T/C cooler.

Often we found on older units that the Fan shrouding, any rubber strips/flaps and cover plating could be missing, this reduces the air flow thru the radiator and cooler further adding to heating problems.

Hope this helps.

Cheers,

Eddie B.