Just for clarification, I have a 933 Traxcavator SN 11A0821 D2 Frame with five bottom track rollers, that was equipped from the factory with Electric Start it also has a WET Clutch. This was not a conversion done at a later date (as far as I know.....No pony motor or any indication on the firewall of having a pony motor installed) I have been working on this for some time and have posted on another thread about my Head gasket replacement. Thought it was time to put down some specifics about what I did.

Many thanks to ACMOC, Old Magnet and his exhaustive research and knowledge and restore49 for walking me though many of the steps and encouraging me to go the route of 42 MT STARTER.

The beginning: Original inertia drive starter was rebuilt last summer and has been slowly failing since. I believe now that I didn't get such a good job done. For one, the "expert" said that no parts were available. I have found a supplier that had all the parts available. Some how I was able to locate all......Hummmmmm.

Cost to rebuild for parts was approx. $440.00. I do have the part numbers for the Armature, Field, Brushes for the original factory starter if anyone wants them. Inertia Bendix parts were not found although I stopped my search after getting the parts price.

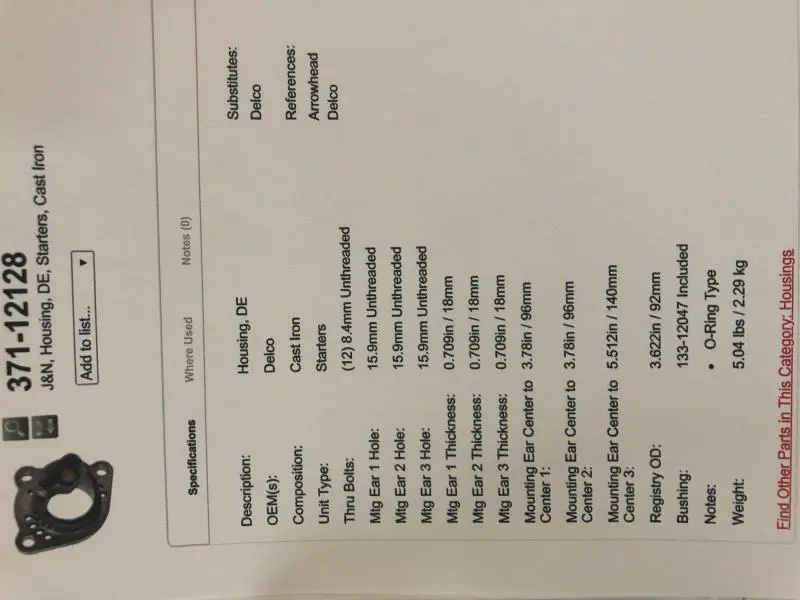

Decision to upgrade into a 42mt starter: I found that four (4) parts need to be obtained. Starter motor.....42mt. I believe they are all similar in their Motor and you will need to remove and replace the Drive End Housing so just finding a good deal on a rebuild 42mt is my suggestion. I purchased this starter (42MT P/N 8200957 from J&N Phone number 800 366 7100) new price was about $270.00.

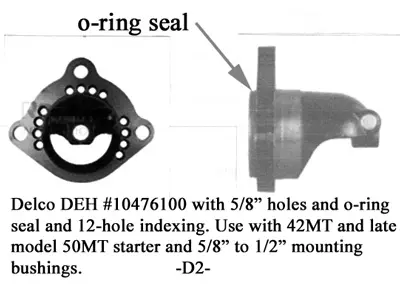

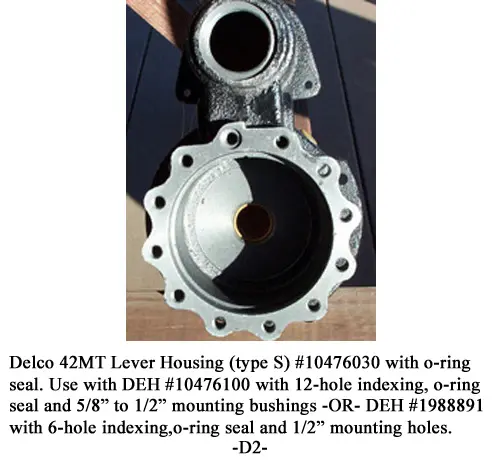

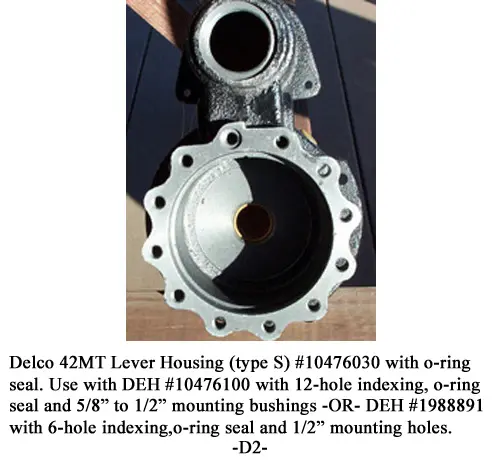

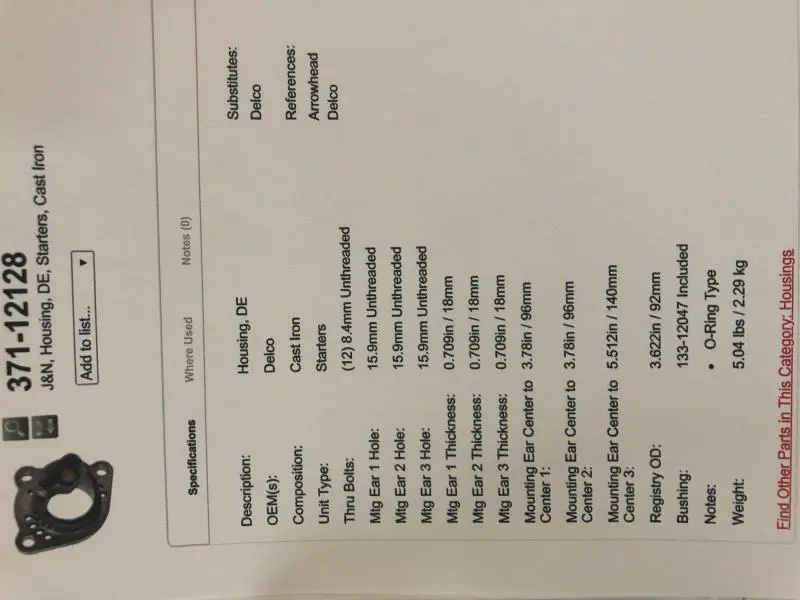

You will also need this Drive End Housing. Part number 371-12129. This housing was a direct proper fit to my existing DEH without any modification for it to fit the three (3) existing 1/2" mounting studs.

NOTE: You do have to modify the DE housing or the Bell Housing and I will detail that a little later in this post. Gasket for drive end to bell housing: PN 180-12141 (sold two(2) per package)

You will also need to purchase a 102751PG [attachment=58353]IMG_0573.jpg[/attachment]which is the Bendix for the starter with the 11 tooth helix gear. I purchased this from VanBergen and Greener in Illinois 800-621-3889. Cost was about $30.00 Just for record/knowledge here is a picture of the original bendix gear [attachment=58358]IMG_0515.jpg[/attachment]

There was a learning curve for me on this installation and required me to install and remove the starter more times than I care to say, luckily I do have an A-Frame with a chain fall and the task really only took about 20 minutes total (once I did it a few times). Remember that this is a Loader and the loader frame is perfectly placed in the way.

Assembly: Once all the parts arrived, this is what needs to be done.

1. Remove the drive end housing from your starter.

2. Remove the Solenoid and housing from the starter. I removed them as a system by just removing the bolt that ties the solenoid to the motor electrically and the bolts on the end of the housing/motor connection. This needs to be done to remove and install the new Bendix. This is a simple task, the Bendix simply slides on to the armature shaft. Note: Do not pull out the armature as it will require you to reinstall the brushes. After the Bendix is installed you can reinstall the solenoid housing and reinstall the electrical bolt.

3. Next step would be to install the DE Housing onto the starter motor/solenoid. This step is where some of the extra work needs to be done.

a. I have found through many of the installations/reinstallations that the DE Housing is not suited without modification for the wet clutch or the fact that the NEW drive gear is larger than the original drive gear on the inertia or the clearance of the nose to the flywheel ring gear.

First modification that I did was to remove 1/16" from the drive end housing on the outboard side to allow for the starter to move to the furthermost outboard location without enlarging the original 5/8" mounting holes that are part of the unmodified DE Housing[attachment=58354]IMG_0630.jpg[/attachment]. As a side note, my first installation did not do this modification and it caused the gear to engage but the gear was stuck in place. I did try this with the engine in Decompression for there was no worry of it starting and destroying my new starter. Once completed, it worked perfectly.

Second modification was to deal with the wet clutch problem. The DE Housing is not suited with an o-ring to seal the connection between the solenoid housing and the DE Housing. This required making a gasket to fit this connection as well as welding up the extra holes in the DE Housing[attachment=58355]IMG_0634.jpg[/attachment] that are there for the sole purpose of clocking the solenoid to clear the engine block, loader frame, bell housing , etc. anything that is in the way. You will see by my photographs the initial welding and the subsequent sanding/grinding to bring the machine surface back to flat[attachment=58356]IMG_0635.jpg[/attachment]. You will also see that for my installation it required the clocking of the solenoid to be inline with the top mounting stud[attachment=58357]IMG_0629.jpg[/attachment]. This made the solenoid clear the bell housing protrusion from the pony motor provision, and the loader frame. This created a small problem of installation of the nut on the stud. To solve this problem I determined what length the stud needed to be cut to so as not run into the solenoid housing once the starter was tightened up against the bell housing. Also a small amount of grinding on the solenoid housing and the nut corners. Special open end wrench was made out of an old router collet tool to fit the width and the small space for the length of the wrench. Note the notch in the end of the tool to accommodate the use of a chisel and hammer to tighten the nut.

Third modification: is the DE HOUSING opening needed modification via grinding the lower opening to clear the flywheel gears. This was minor and easily checked by just installing the DE Housing separately into the bell housing to verify clearance.

The sealer that I ultimately used was an aircraft fuel tank sealer, (my brother is an aircraft mechanic and turned me on to this product: Aircraft Spruce: AC TECH AC-350 B-1/2 3.5 OZ KIT AMS-S-8802

Part #: 09-05593

This is a two part type sealer with about 1/2 hour working time. Other time frames are options. This worked for me but it was 50 degrees in my shop. Any hotter and it would have been a trainwreck!!!

I applied this sealer to the solenoid housing/DE Housing connection and filled all unused mounting holes, installed the DE Housing to the solenoid housing and then proceeded to apply the sealer to the DE Housing/Bell Housing connection and gasket. Use gloves as this stuff does not want to come off with any known solvent. Only time and layers of skin. I then lowered the starter into the final location with the chain fall and installed the two lower mounting nut (partially as the upper nut needs to be started prior to the starter being pushed up against the bell housing. A long nose needle nose pliers was very useful. Making sure that the nut moved effortlessly on the threads was critical to ease the installation of this nut. Once this nut was snugged up I proceeded to tighten the two lower nuts and then back up top to do final tighten on the top nut. In the process of tightening the lower nuts I used a pry bar to move the starter to the outboard most location. Installation of the starter completed with the connection of the wire from the start switch to the solenoid and the battery cables to the main starter studs. This sealer is tough stuff and I would recommend that you install the starter and test that it is all aligned and working properly before you do the final installation with this sealer. I went this way with the sealer as I had already purchased this for a previous project and did not use it. Other sealers/gasket makers may just do fine but this is what I used. Hope I never have to remove this starter again!!!! I will edit tomorrow with the installation of photographs outlining a few of the steps that I think will help you all understand each step I took. Hope this helps someone in their project.