You have a wonderful day. Best wishes. Deas Plant.

Hi, bboaz.

I am open to correction here but I thought the clearance between the clutch fingers and the release bearing was supposed to be 1/8 of an inch.

With the clutch pedal depressed, can you get in there with something like a power hacksaw blade sharpened across the end and try to wedge the clutch plate away from the flywheel working progressively around the full circumference?

IF you try this, DO NOT drop this blade - or anything else - into the clutch housing - unless you like awkward fishing expeditions.

Another 'trick' might be to tow the grader with the engine shut down, decompression at "Run", Throttle at the "Stop" positiion, the transmission in a low gear and the clutch pedal depressed - like trying to loosen stuck steering clutches inna crawler..

Just my 0.02.

I once had a oil clutch in a 9u D6 stick. Once opened up the drive shaft on the oil pump was broken, so no oil circulating. The seal was out on the out put shaft to transmission. So I assumed we had been careless in adding oil, and had dust get in the compartment. After I tried to keep a paint brush in tool box to better clean around the vent/filler cap before removing. But with the tractor having around 15,000 hour at that time maybe the shaft was tired. As the bushings in the pump were not real bad. Well the hours are just a educated guess but the hood had number of 7000 to 9xxxx scratched in which I assumed were times the oil was changed. But no information has ever come to light as to the first owners. As I bought it from the bank after a big time but very short lived cattleman that went to prison for his deceiving the bank.

I am not recalling any damage to the clutch surfaces, as I only replaced one clutch plate because the outer drive teeth were almost gone. The old guy I used for help that had made his living as mechanic said he had never seen the friction surface wear out always the drive teeth were first to go in Cat wet clutches of the 1950's.

So with that said is there anyway to see if oil is circulating on the grader clutch arrangement? Without taking it all off the grader.

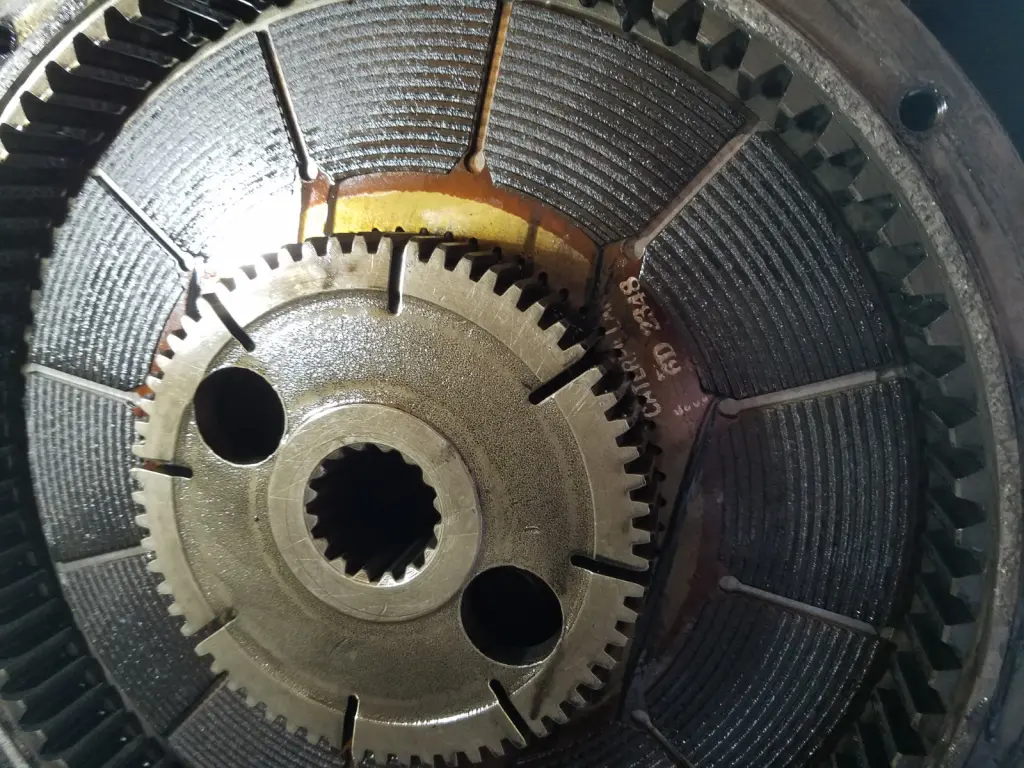

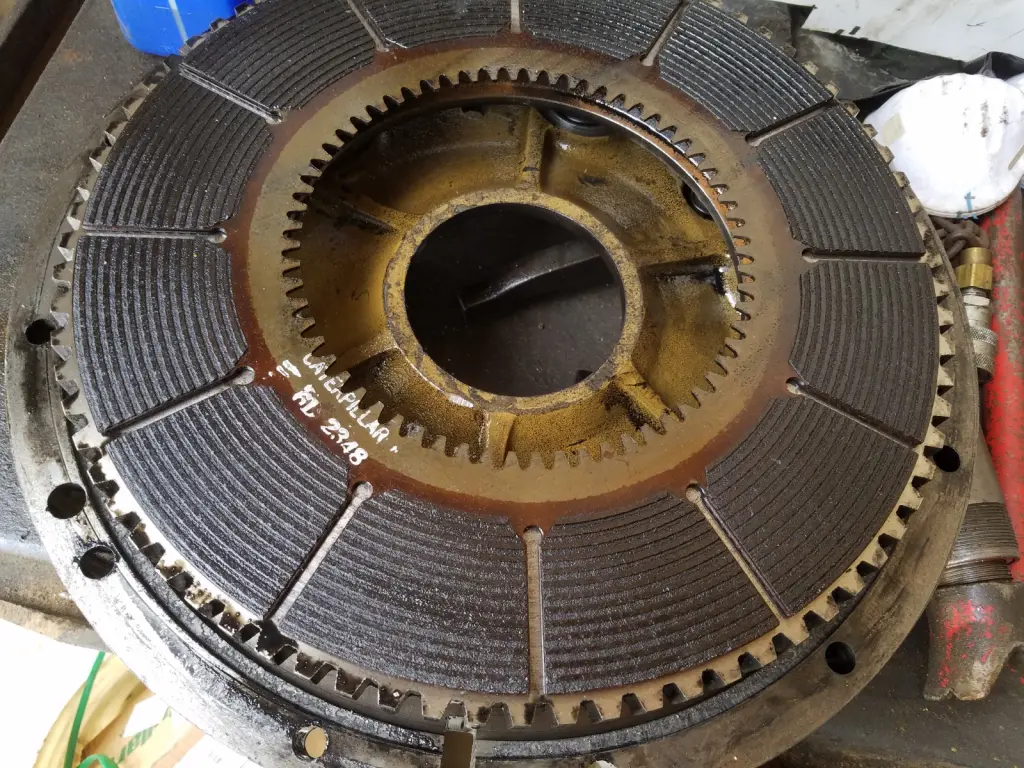

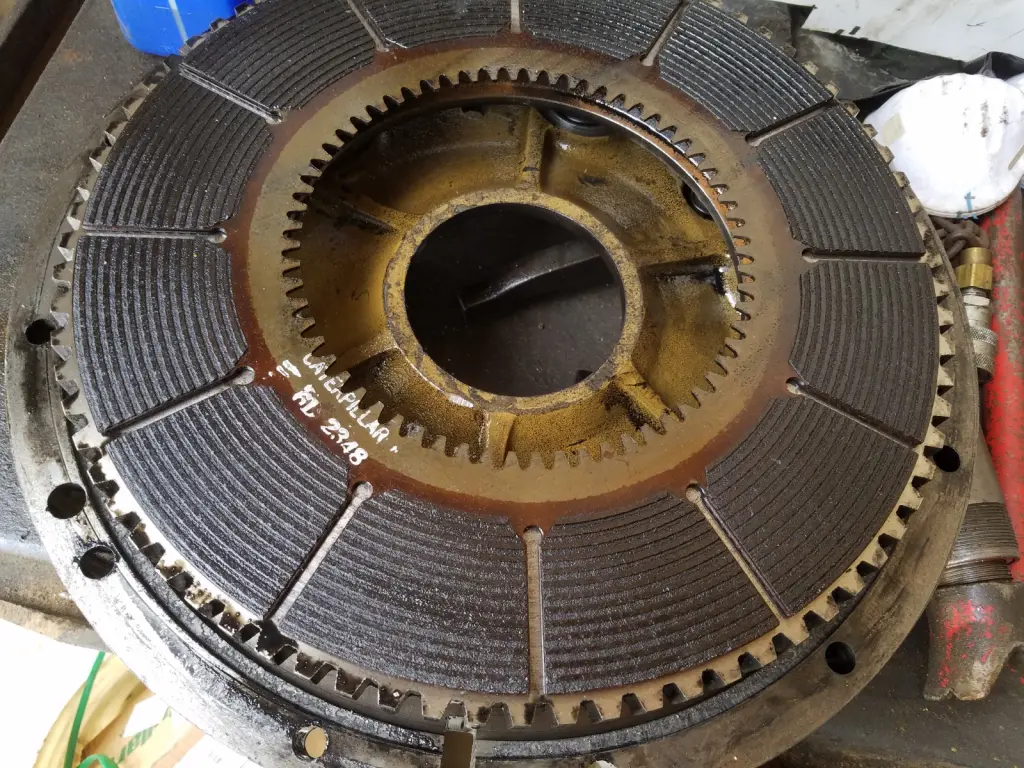

Pulled the motor to get to the flywheel clutch. The friction disk (6D234😎 are stuck to the flywheel (1) and to the Pressure plate (2). No rust and oil on everything. There looks to be a form of residue from the lining material on the center metal disk like the material from the lining has bonded itself to the center disk. I have not pried the disk off the pressure plate or the flywheel yet, I want the owner to look at it first. Nothing is discolored to indicate it got hot. Never seen anything like this before.

[attachment=72039]20230430_110952[1].jpg[/attachment][attachment=72040]20230430_111015[1].jpg[/attachment][attachment=72041]20230430_111006[1].jpg[/attachment]

You have a wonderful day. Best wishes. Deas Plant.

Hi, bboaz.

HMMMMMMM????????????? Int'restin'.

Just my 0.02.

Hi bboaz,

Don't they have an oil clutch that is feed is from the main engine that's why there's oil all over it?

I would just clean up the steel plate in the first photo and you should be right to go.

Regards

You have a wonderful day. Best wishes. Deas Plant.

Hi, rax200.

It was stated at the start that this is an oil clutch. Personally, I would like to know more about WHY it stuck before rushing into 'gitterrunnin' ' fixes. But that's just me.

Just my 0.02.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

how long had it sat for?

has the oil attacked the friction coating? if so what has caused the oil to do that has it became acidic or something?

This machine set for about 6 months. It took a pry bar to unstick the friction disk off the flywheel and the pressure plate. Each time I would pry one of the sections loose it would pop. They were really stuck tight. The friction disk stuck to the flywheel was also turning the center hub as in picture #2 which turned the input shaft to the transmission not allowing it to shift into any gear. There was some residue from the disk on the flywheel and pressure plate from the disk which came off with sandpaper and smoothed up the surfaces again. The clutch brake is operational, when the clutch is pushed all the way down the input shaft to the transmission cannot be turned but it was not enough to break the disks loose. Even driving the machine with the clutch engaged was not enough to break the disks lose. I really don't know how he got it started in gear but he managed to drive the machine about 4 miles to get it to my shop. I didn't even bring that subject up. The question is, Why did they stick in the first place. Spoke with a long time retired Caterpillar Mechanic that stated he had seen this a couple of times but it was very rare. He had no explanation for it either. I have new friction disks ordered to put the machine back together with. bboaz.