The rims on Caterpillar equipment are not the Widowmaker type. I have never questioned whether one would hold as it was being inflated but I do use a clip-on chuck and back away once the bead seats and pressure begins to build.

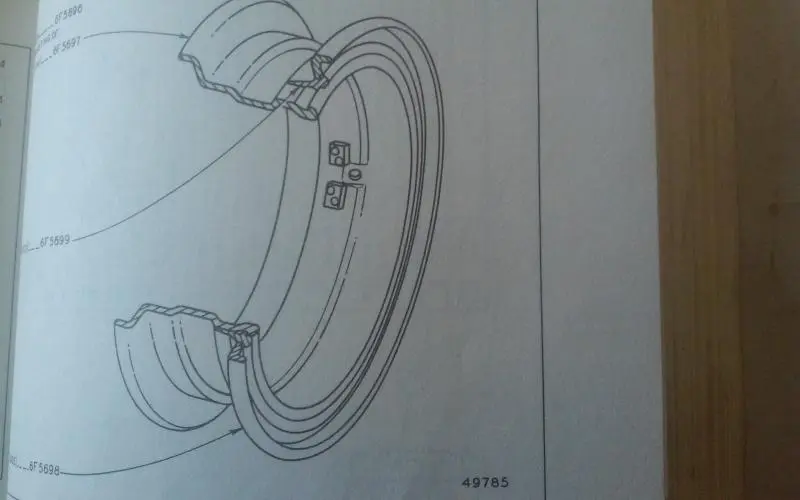

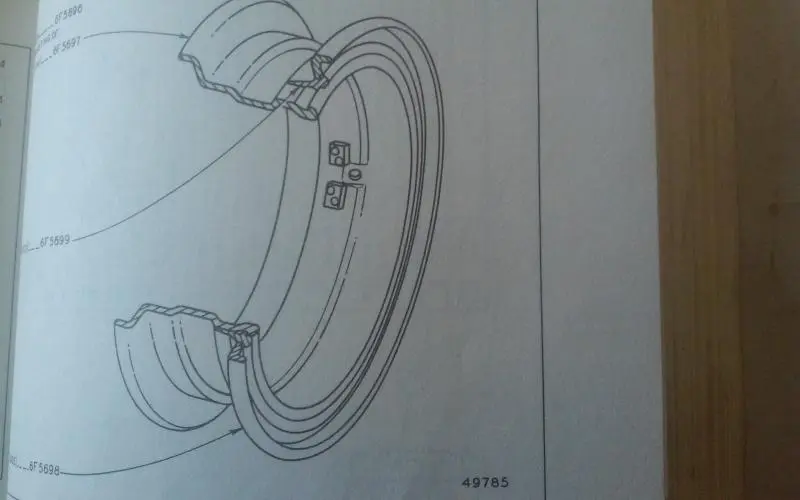

I am unfamiliar with the pegs you are describing but I have seen wheels where the locking ring was riveted onto the rim flange on one side of the split so it would not be lost or perhaps mismatched.

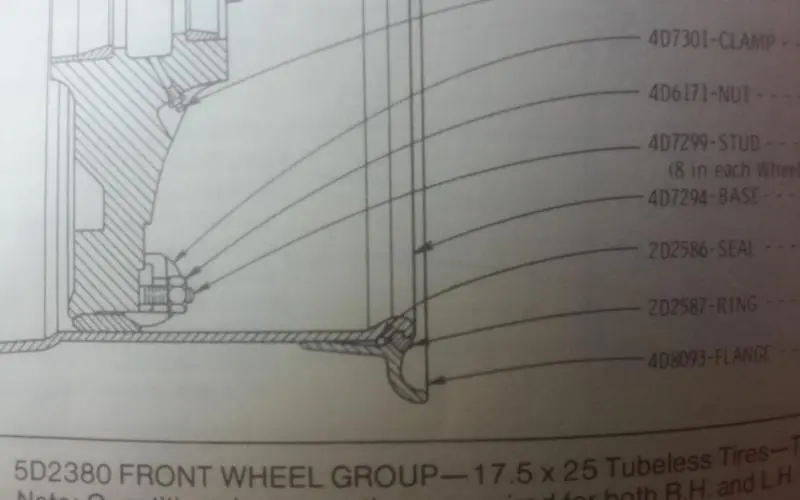

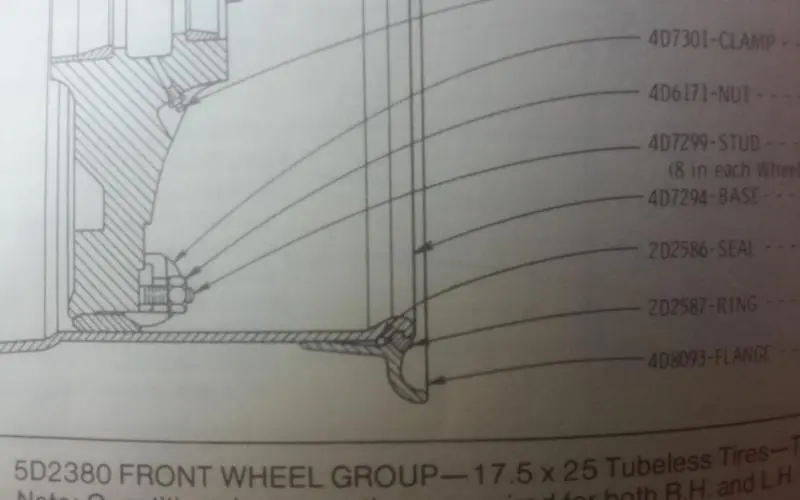

First some terminology so you know what I am talking about.......the rim base is the large section with one rim flange and the cleats or center to mount the assembly on the machine. Then there is a removable outer flange ring with a tapered bead seat on the inside and a chamfer cut in its outer surface to squeeze the lock ring tightly into its groove in the rim base, locking the rim flange ring securely onto the rim base.

The trick is to get the locking ring to fit tightly in its groove and clean all rust and dirt from the parts so nothing interferes with it gripping the rim base and being compressed tightly by the rim flange ring moving outward. If it doesn't fit perfectly, usually it is bent open a little so it doesn't grip the rim base tightly. If its bad i might try reshaping it by running it through a clevis or jaws of a vise and springing it closed with hand pressure or possibly using a tool of some kind. The end result should be a ring that is flat and whose ends butt up together. When you spring this open and force it into the groove in the rim base it holds itself in place until the flange ring moves out and traps it.

Obviously if the rim base groove or the lock ring are rusted badly, so they do not engage securely, do not try to reuse the parts,

When the lockring is just a little loose in its groove, I will clamp it in the rim base groove with several pairs of visegrips spaced evenly around the circumference. You should be able to clamp the pliers on so the jaws don't prevent the flange ring from moving outward and trapping it the lock ring so it cannot slip out of its groove as the flange ring tightens against it. The flange ring may have to push the visegrips out of the way as it moves out all the way, so do not put them on too tightly.

Finally you need lots of tire mounting grease and plenty of air.

Put a good coat of grease on the beads of the tire, put it on the rim,

put the flange ring on and press it down into the upper bead of the tire so it seals.

Put o-ring in its groove in the rim and coat it with grease.

Install lock ring as described earlier.

Remove valve core and attach airline to the stem and inflate tire pushing the flange ring up against the lockring and sealing against the o-ring.

If you cannot get air in fast enough to expand the tire and push the flange ring up, you can use handsful of the grease to pack the area between the flange ring and rim base. The stiff grease will allow enough pressure to build up inside the tire to move the beads out. Once you get this going right you don't want to be monkeying around with the lockring, wondering if it is tight in its groove etc. Take care of that ahead of time!

D2-5J's, D6-9U's, D318 and D333 power units, 12E-99E grader, 922B & 944A wheel loaders, D330C generator set, DW20 water tanker and a bunch of Jersey cows to take care of in my spare time😄