"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

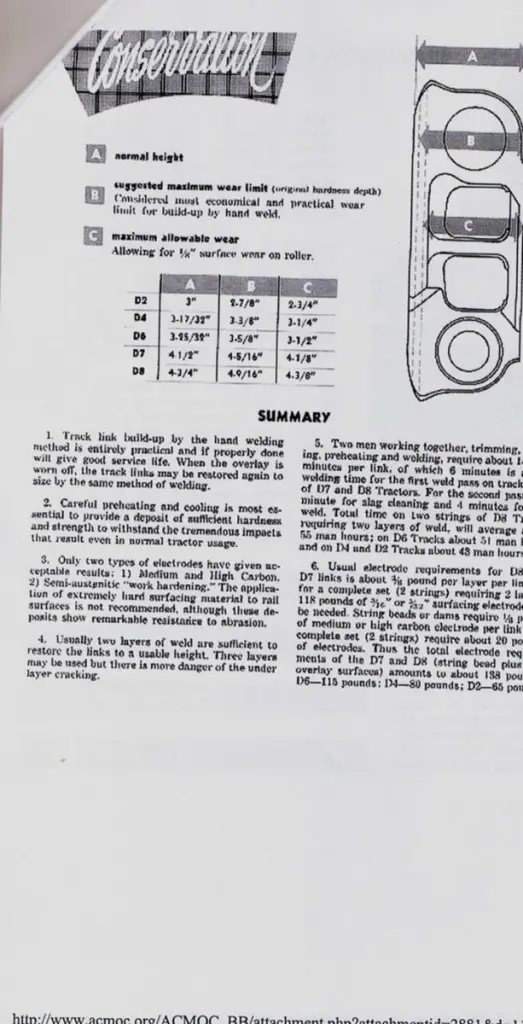

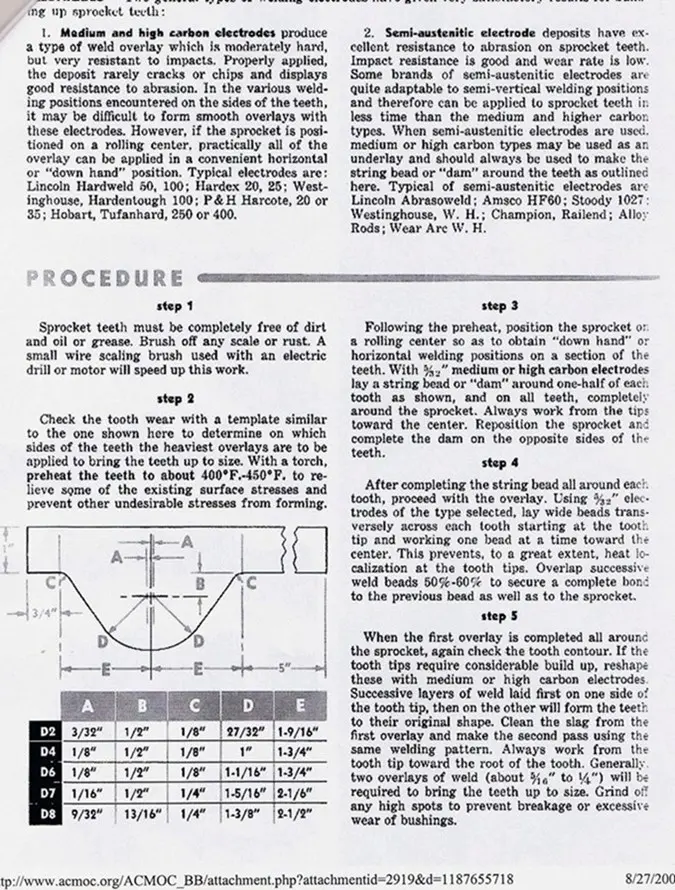

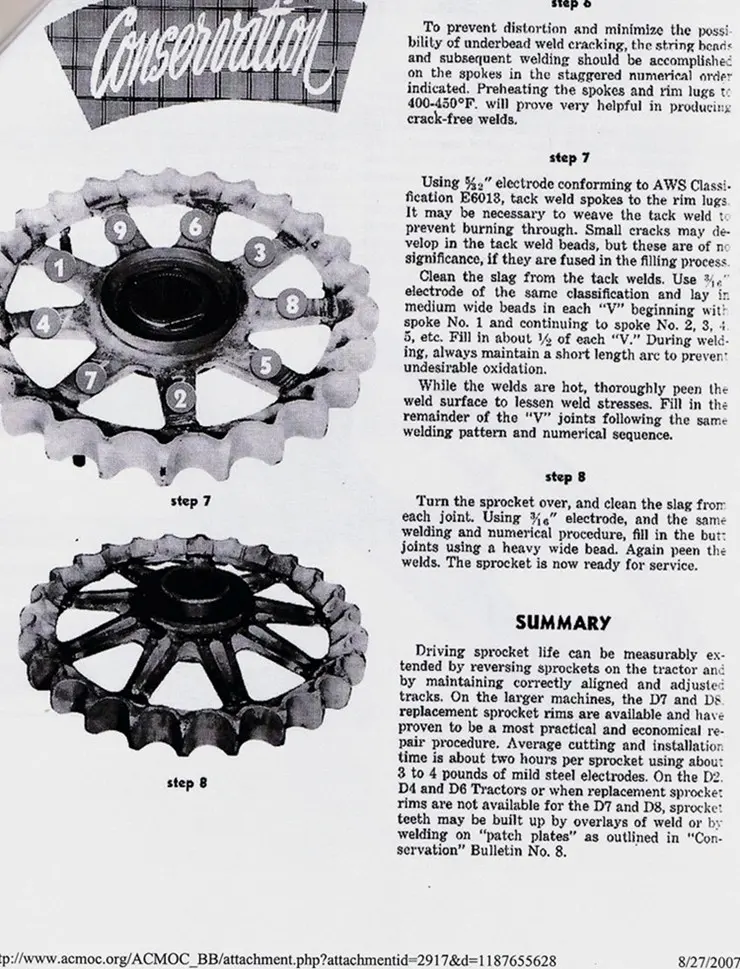

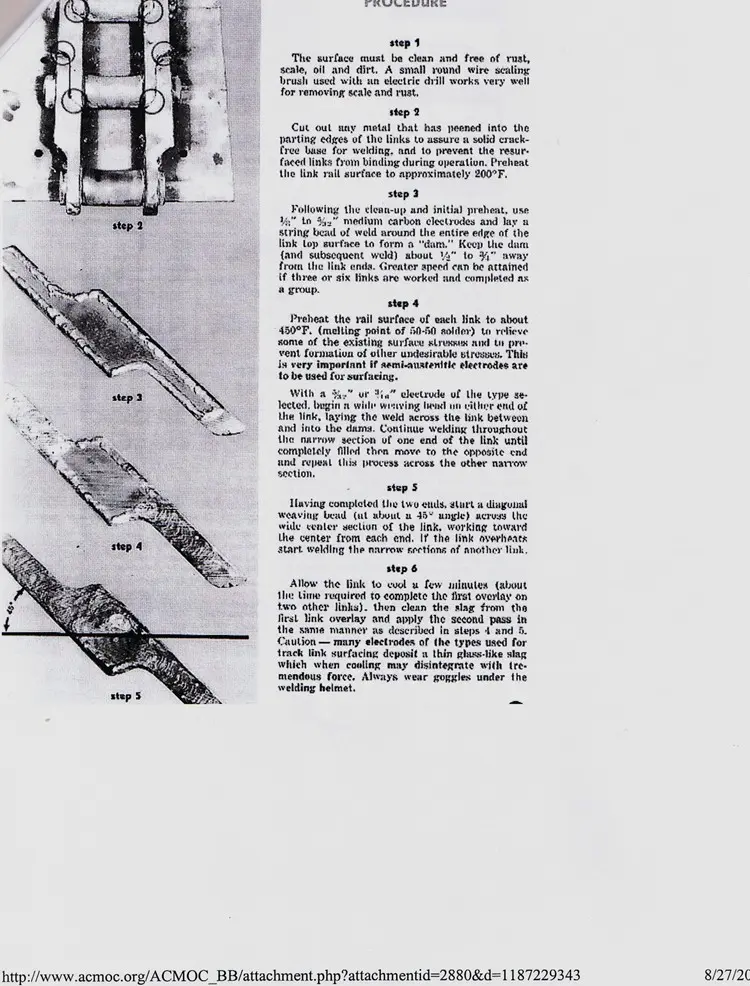

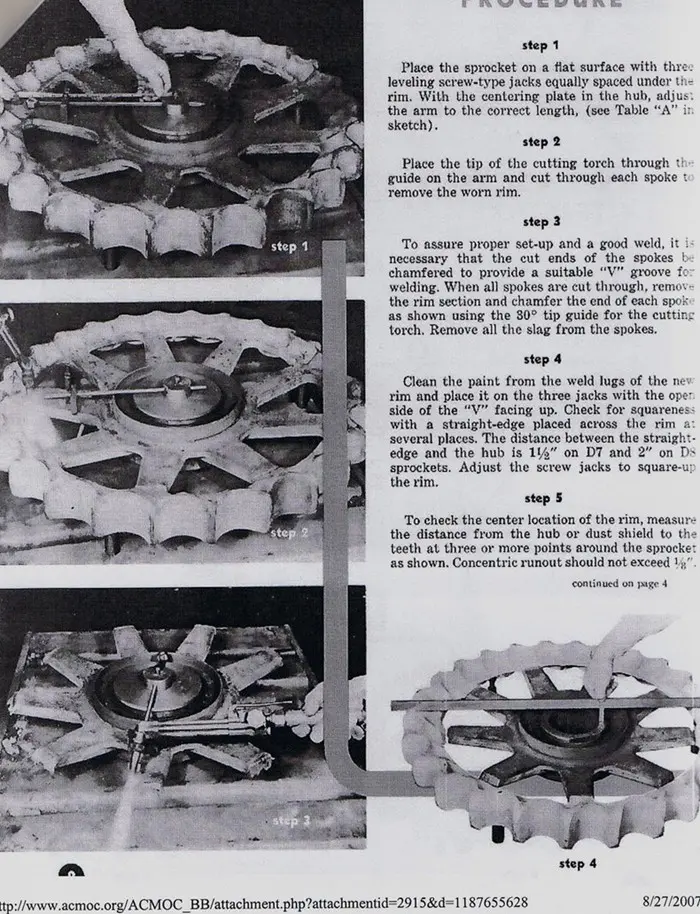

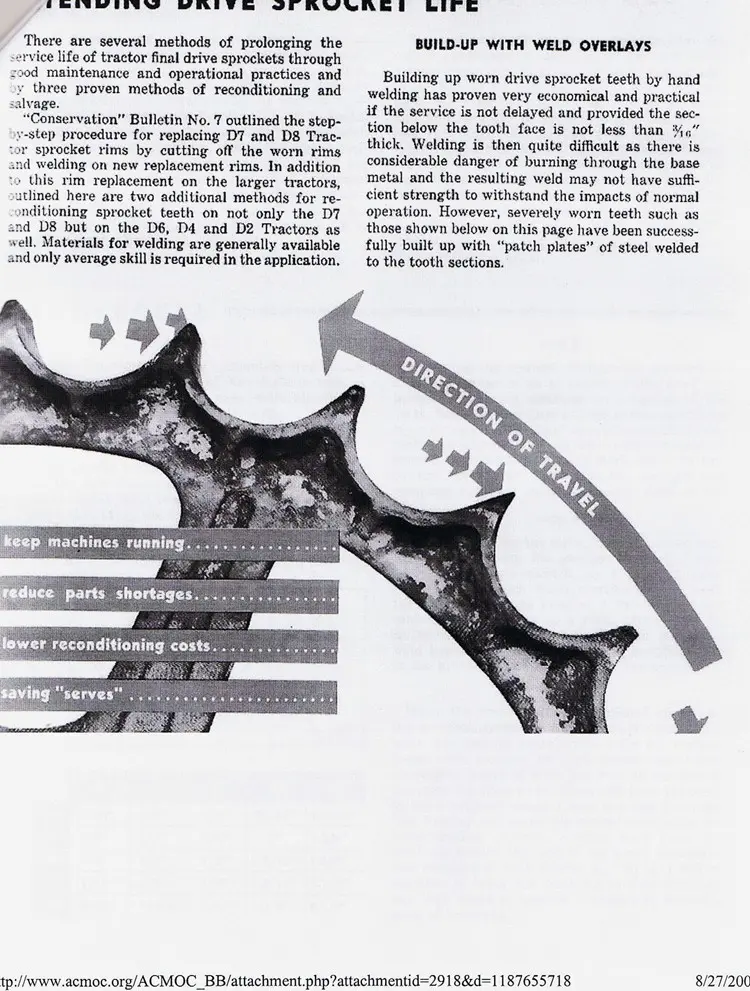

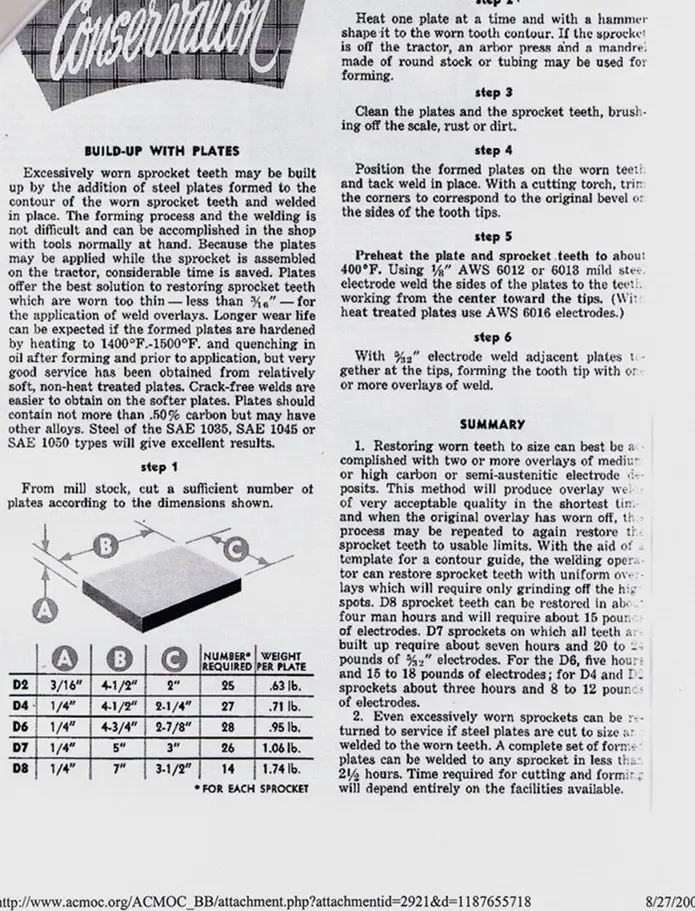

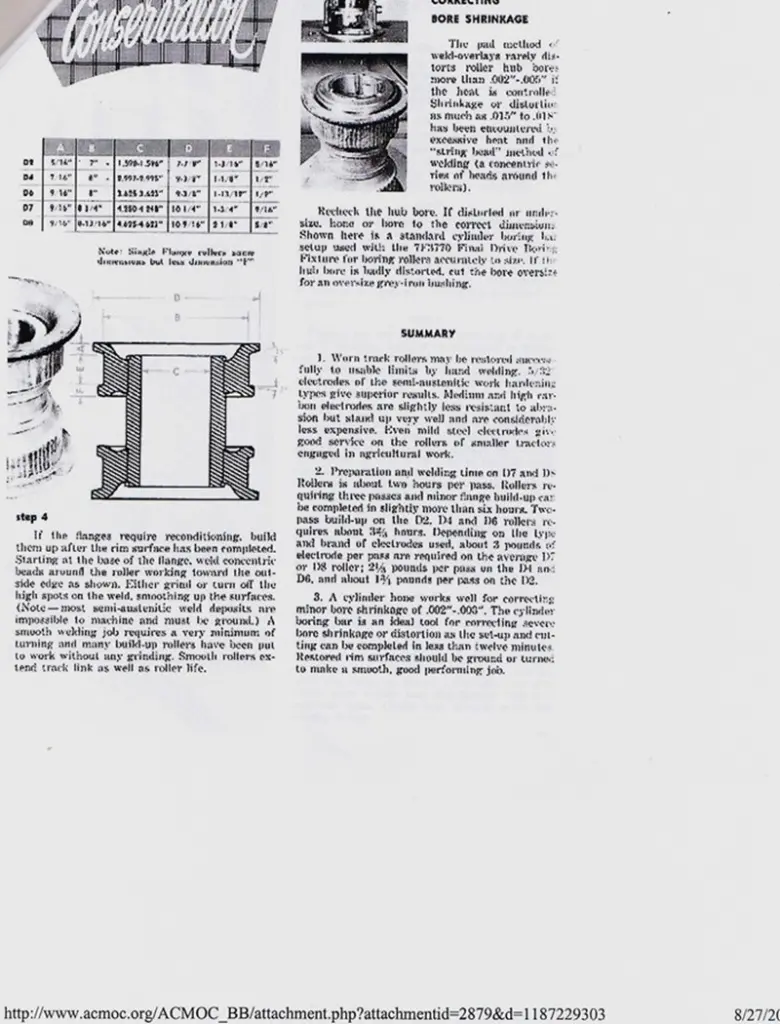

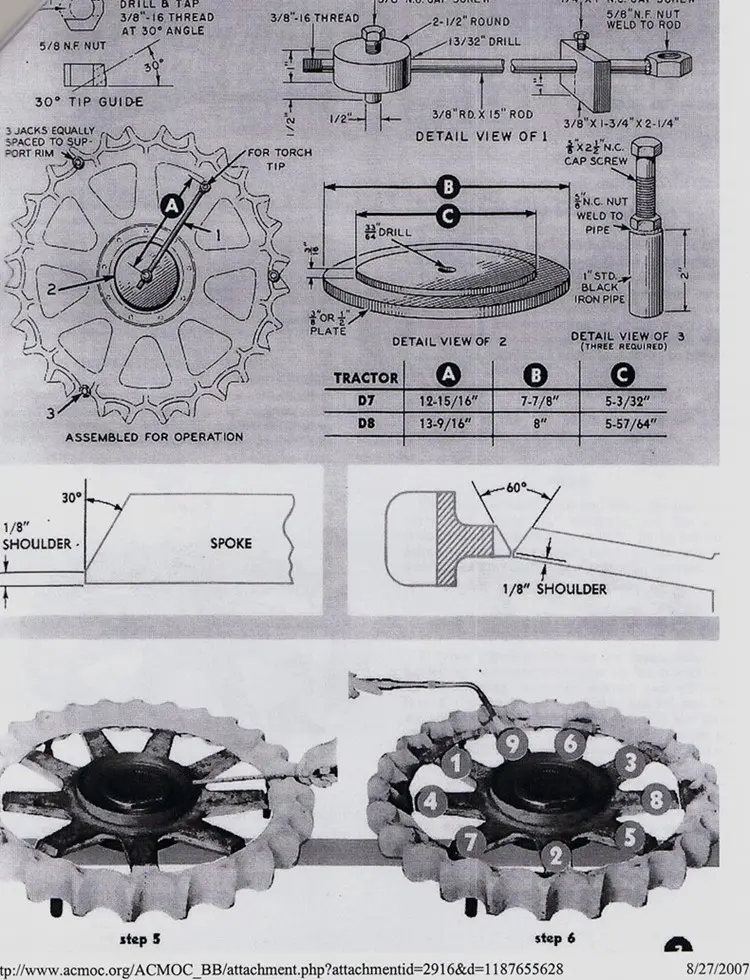

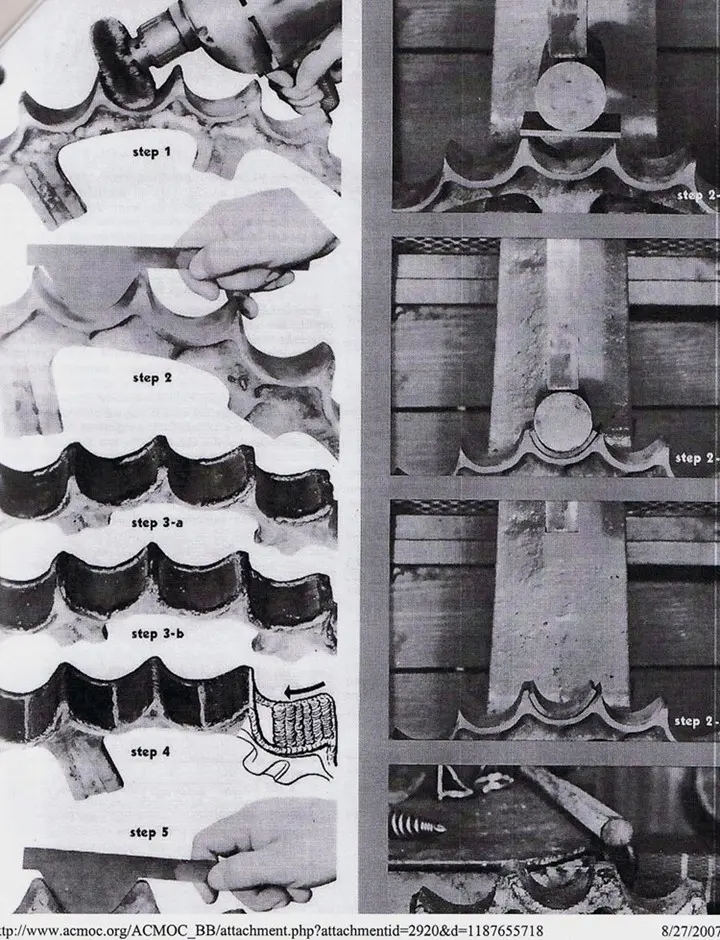

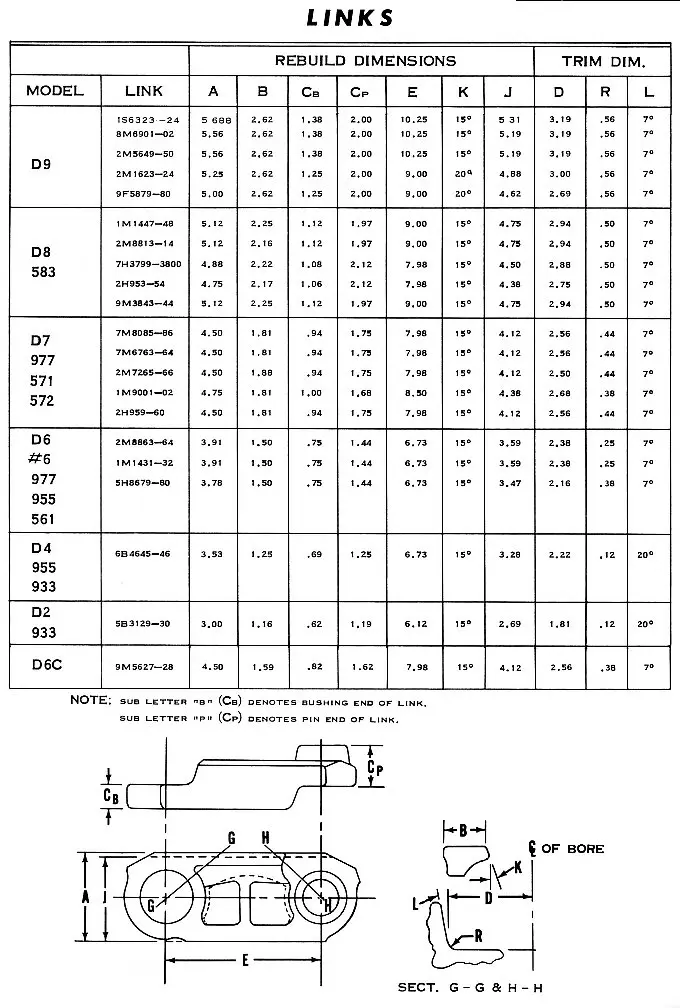

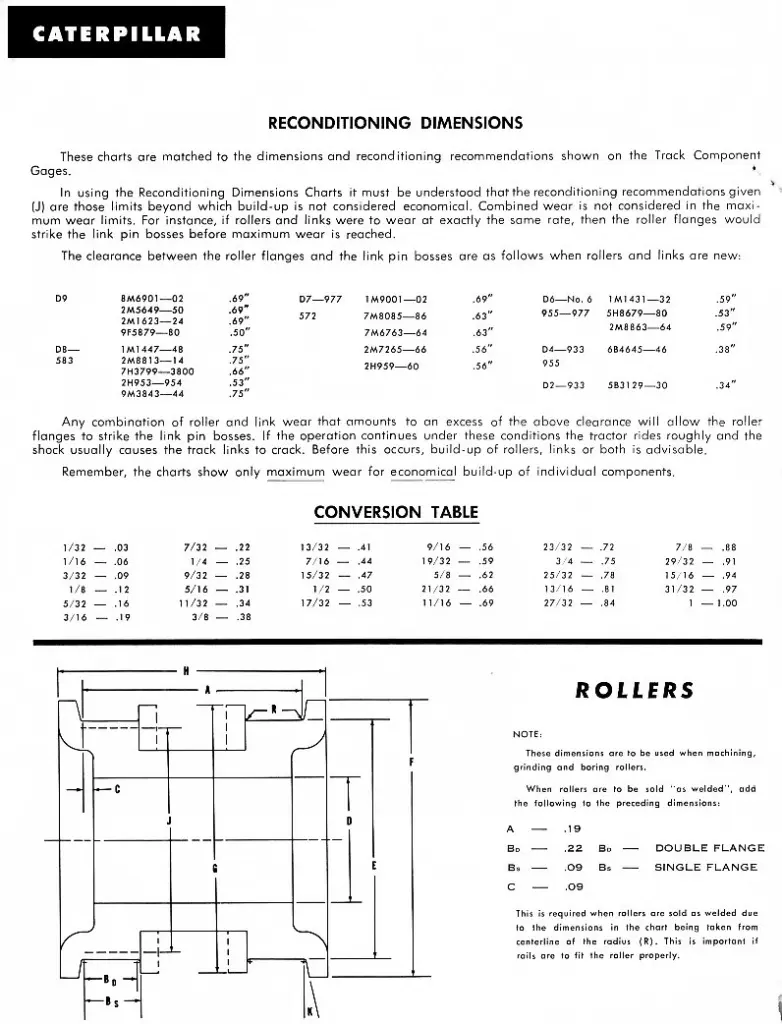

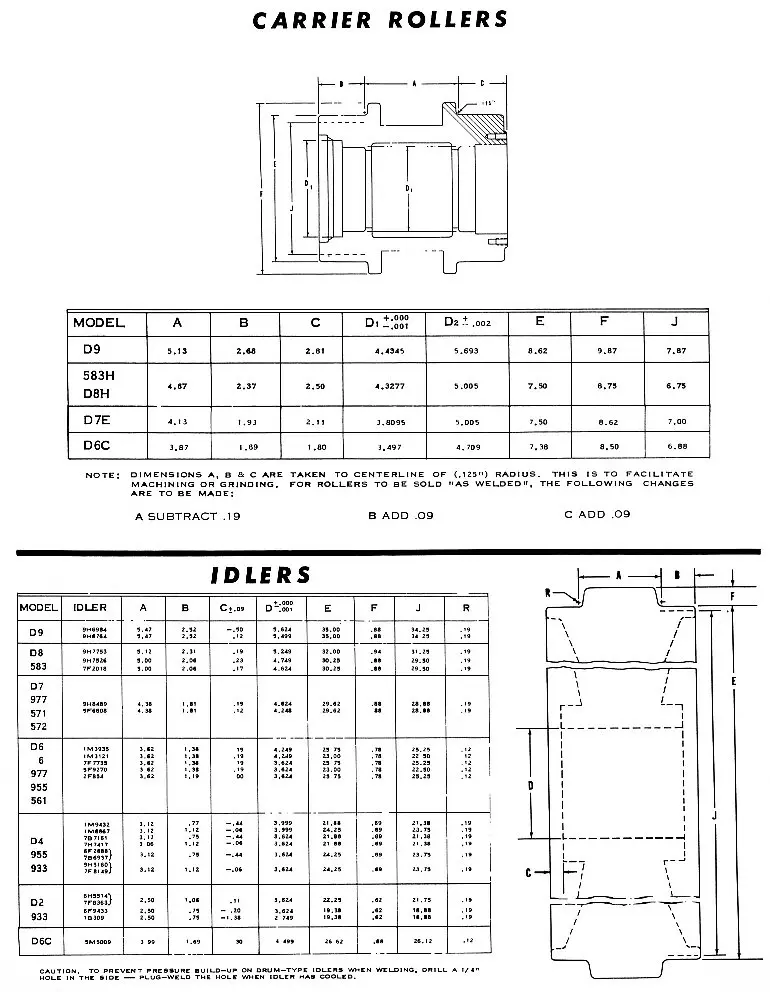

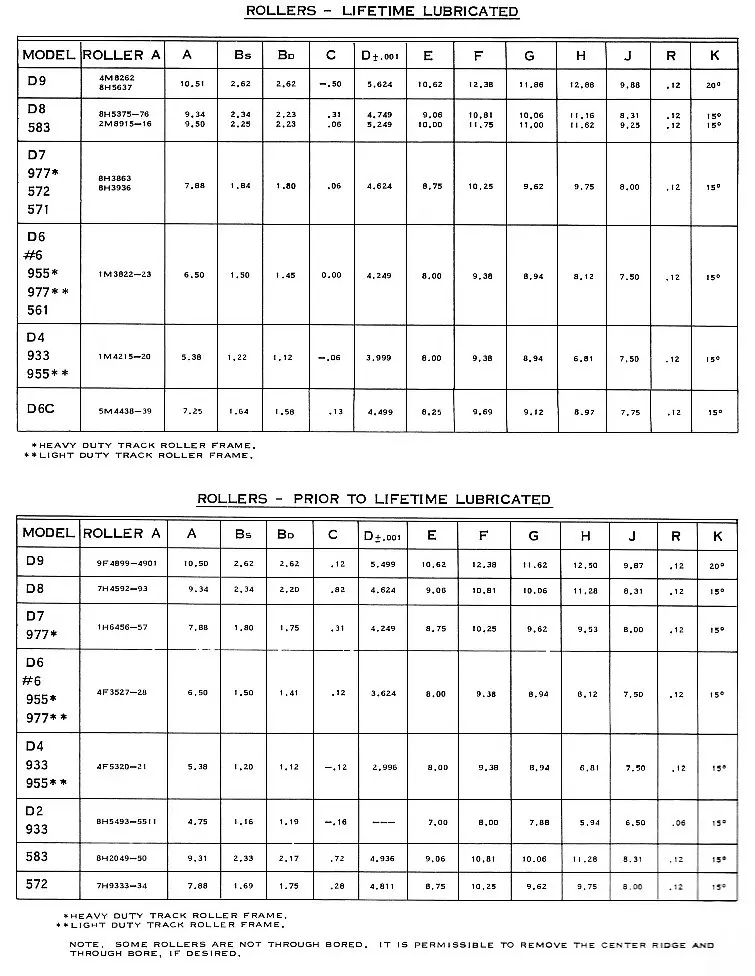

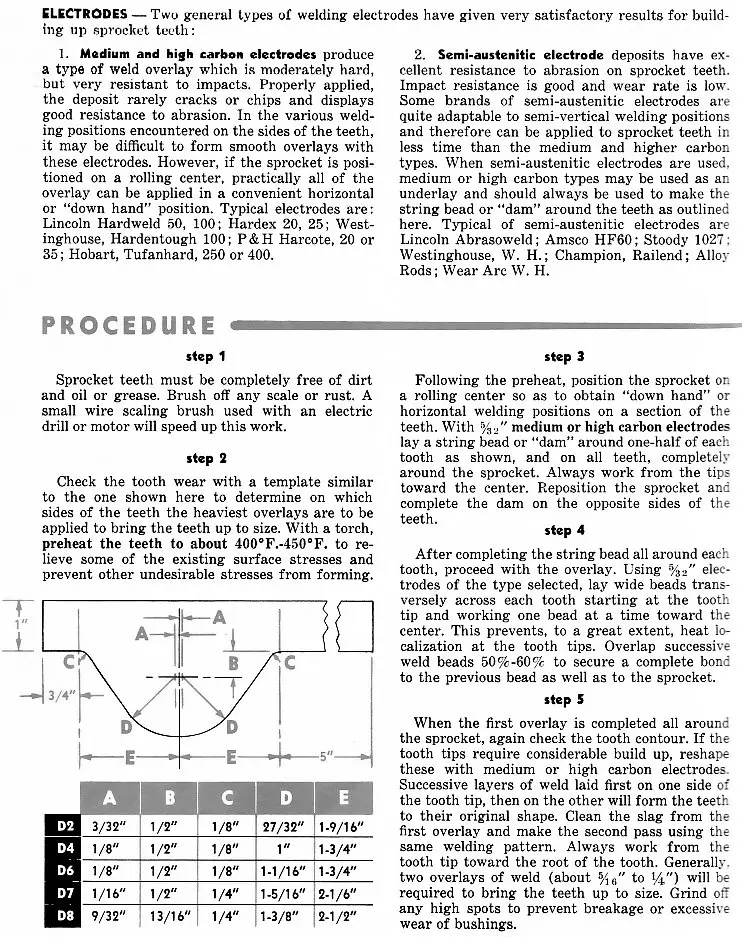

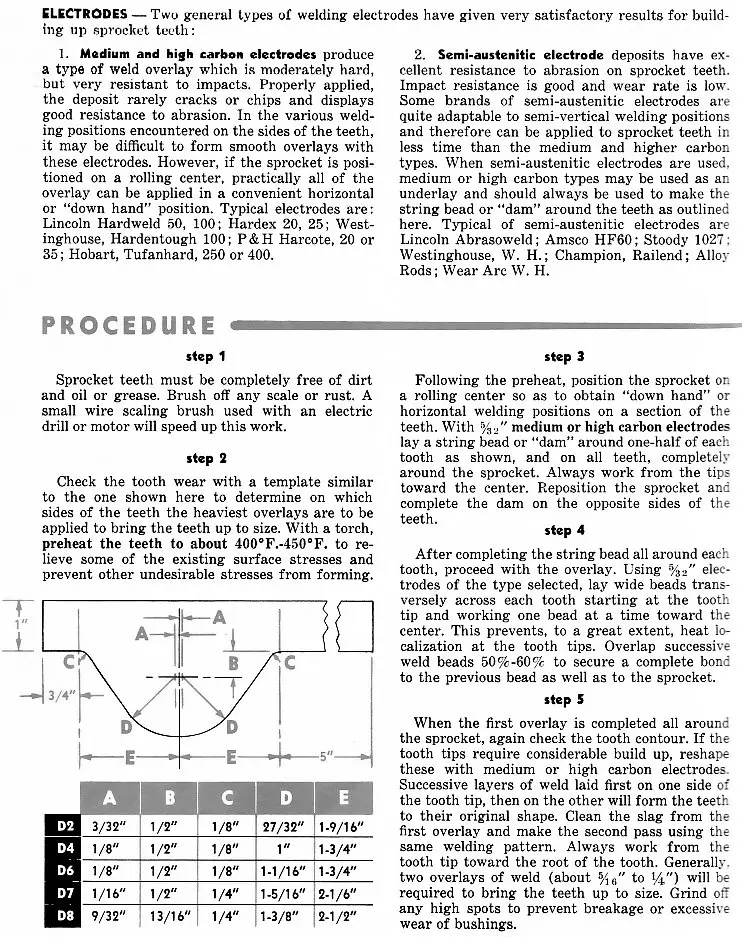

heres some data about reconditioning by welding.

[attachment=68207]UC_weld_repair_009.jpg[/attachment][attachment=68208]UC_weld_repair_013.jpg[/attachment][attachment=68209]UC_weld_repair_006.jpg[/attachment][attachment=68210]UC_weld_repair_004.jpg[/attachment][attachment=68211]UC_weld_repair_012.jpg[/attachment][attachment=68212]UC_weld_repair_002.jpg[/attachment][attachment=68213]UC_weld_repair_005.jpg[/attachment][attachment=68214]UC_weld_repair_008.jpg[/attachment][attachment=68215]UC_weld_repair_011.jpg[/attachment][attachment=68216]UC_weld_repair_003.jpg[/attachment][attachment=68217]UC_weld_repair_007.jpg[/attachment][attachment=68218]Stoody Reco Dim 4.jpg[/attachment][attachment=68219]Stoody Reco Dim 1.jpg[/attachment][attachment=68220]Stoody Reco Dim 3.jpg[/attachment][attachment=68221]Stoody Reco Dim 2.jpg[/attachment][attachment=68222]tooth rec 2.jpg[/attachment]

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

any of the soft hardface electrodes so abrasicord 600 etc

thank you Trainzkid88....yes there's loads of information in those conservation manuals...anything is possible with time and effort (sometimes you have to give up flogging a dead horse though)

-was mainly looking for personal experiences with regards to wear and toughness of rebuilding with 7018 etc..?

-and the Rockwell Number of 7018...if anyone has references...or ?

https://www.google.com/search?client=firefox-b-1-d&q=Rockwell+Number+of+7018

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality