Hi OF,

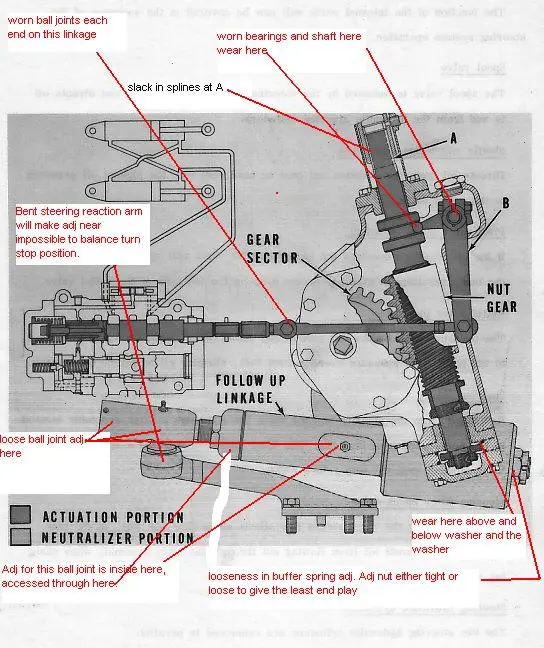

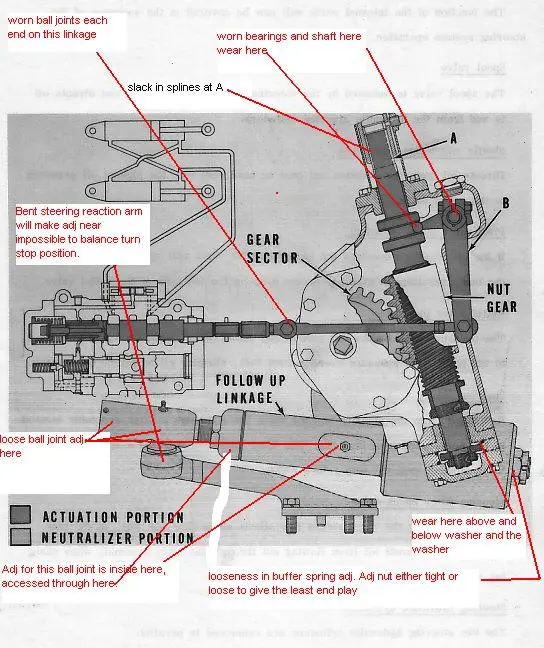

Scans below from a 966B are basically the same setup and so may help--it is an accumulation of wear in the ball joints and other areas as outlined--wear can also be in the box itself at the signal lever that connects to the hydraulic valve where the end of the lever engages the sleeve groove and so moves the lever as the worm rises and falls as turns are made--usually this is a place of lost motion that causes slow turns.

The rose joints on said linkage rod can be worn causing lost motion also.

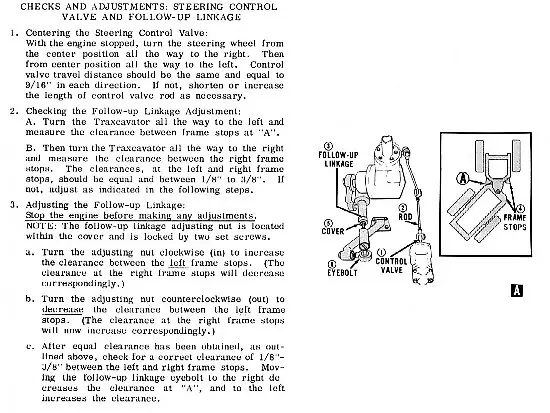

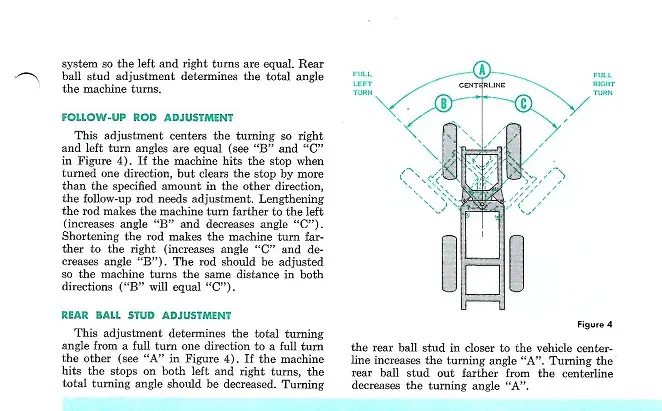

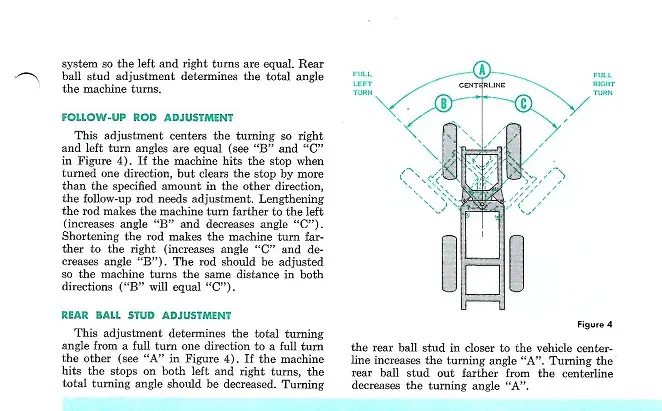

One scan covers turn centering and the amount of turn so it does not clash with the stops when turning.

Had several machines with bent front frame connection arm being bent due to accident damage or being forced to turn when engine not running--in this scenario the steer wheel needs to be turned to keep up with turning speed prevent loading the connection arm when outside force is used to say straighten a machine for pushing with dead engine or such.

Hope this helps.

Cheers,

Eddie B.

Hi Team,

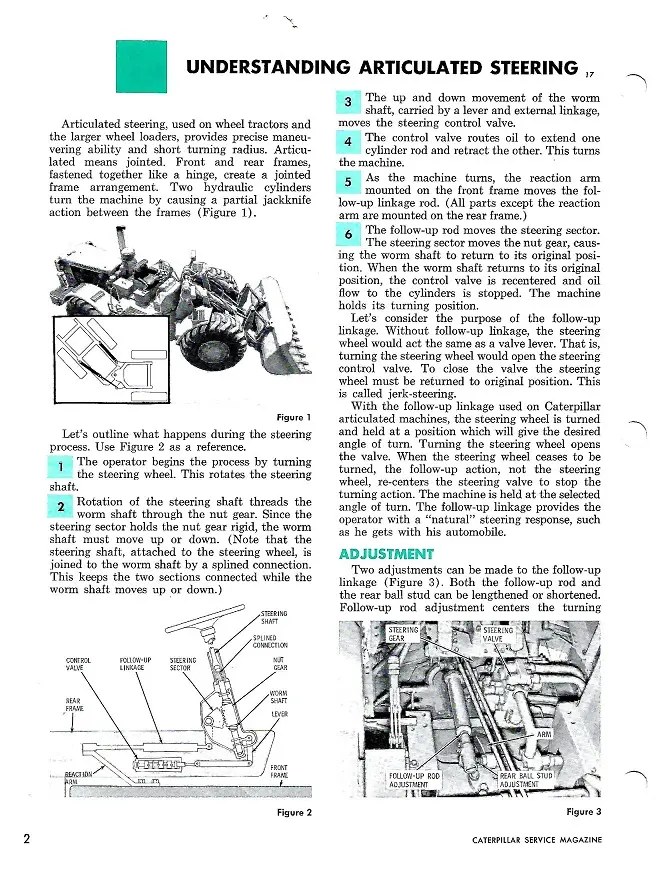

looking for something else I found this Service Magazine article and have added the scans below.

S/Mag. June 15 1967.

Cheers,

Eddie B.

Thank you again, Eddie B.!