You are not capturing the oil flow to boost one side. You should pull the lever back, feel resistance and then feel the lever move easier as you continue to pull back when the oil flow in the booster gets trapped in front of the piston. The oil flows through the center of the pistons untill you pull a lever and the plunger comes back and closes the hole off. Try both levers at once and see if you get boost on both levers.

Later Bob

ok, i'll try. thanks dw

Hi Daryl,

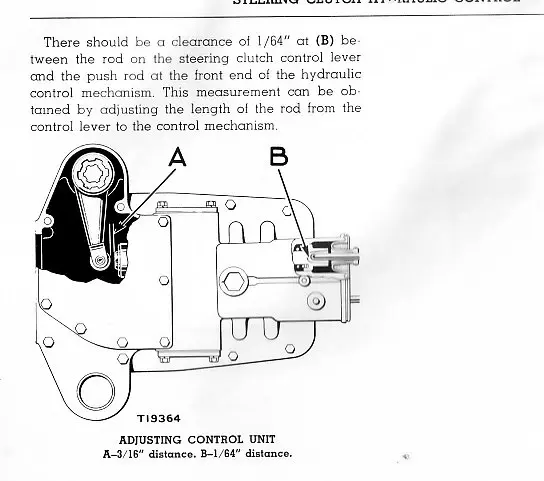

below are scans from the Service Manual on the adjustment of the booster linkages, if you have not got them. Also is the system operation.

Be sure the booster is full of oil to the bottom of the thread in the filler neck of the booster.

Adjust the linkages as described and see if you have success.

Grab these now while they are up.

Cheers,

Eddie B.

Hi Daryl,

below are scans from the Service Manual on the adjustment of the booster linkages, if you have not got them. Also is the system operation.

Be sure the booster is full of oil to the bottom of the thread in the filler neck of the booster.

Adjust the linkages as described and see if you have success.

Grab these now while they are up.

Cheers,

Eddie B.

Before you start adjusting things are the linkages moving free?I do a lot of work with my tractor around trees and little sticks smaller than a pencil will get between the steering lever and the little rubber bumper under the floor plates.The clutch is released but if there is not any free play on the one lever the other side doesn't provide any hydraulic boast to the other side. So make sure the lever is all the way forward on the side that works.

But if this and adjustment don't fix it then you can be having the throwout bearing going bad.This always feels like the boaster is just not putting out on that side.Hope you don't have to go that deep to fix it.

Ray

The push rod into the booster is just a ball & socket affair. If dirt/rust/crud is keeping the "piston" from reaching the forward end of it's stroke, it will cause the same situation as described regarding free and full movement of the linkage and levers. Some times you can remove the rubber boot and clean and oil where the push rods go in and get results.

thanks for the advice, haven't had time to work on it yet. dw

The oil leaks out of the resevoir after a few hours of use , Where is it going and is it very hard to fix? Boosters work great when oil is full> Thanks, Steeltracs

Hi Steeltracks,

oil can leak from a few areas on the booster unit.

1 is out of the pump drive shaft seal and into the bevel gear/trans oil compartment.

2 lower pump and sump gaskets under the booster into the above area.

3 out of the servo shaft seals each side of the main unit body into the respective side steer clutch housings.

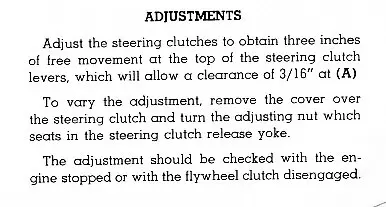

4 out of the steer lever push rods--you can see this leak at the front of the booster, these are the hard ones to fix as you need to pull the alloy seal retainers to get the seals out without destroyin/gouging the carrier bores.

The others require lifting the fuel tank a bit to get the booster out. They are awkward and heavy as they need to lift straight up to disengage the clutch yoke splined shafts.

If you remove the big round rear cover plate of the main bevel gear housing you can see the booster sump etc and maybe see where your major leaks are--provided you have no rear attachment on the rear of the machine.

Hope this helps.

Cheers,

Eddie B.