Pulled my 922b wheel loader out of the weeds this week. The antifreeze jug AND the plastic bucket had cracked and let water into the exhaust!

But, the engine turned through two revolutions with a socket on the crankshaft pulley bolt and I need it to handle some bulk bags of seed that are just a little too heavy for my skid steer loader. So, after cutting the saplings out of it and airing up the tires we blocked the loader boom up, chained the bucket so it would not dump the accumulated debris from about 10 years of sitting, chained the rear to the top quick hitch hook of a largish tractor and took it to the shop. Trip was uneventful except I was reminded the rear axle seals leak gear lube into the CV joint spaces whenever the axle is tilted. Got to the shop with just a little dripping down the tire on the low side, but over the next couple hours , the rest of a quart or more drained out of the CV "ball" housing onto the floor.

Long story short, pulled injectors, added diesel to cylinders to mix with water etc, covered holes with a heavy rag weighted with a big wrench and turned it over with starter. Then dried out PC chambers with compressed air and reinstalled injectors and attempted a start. No fuel up to pumps so I started chasing that. I think I have gotten to the bottom of that now by fixing a crack in the fuel filter base and am waiting on lift pump shaft seals and new injectors. It runs pretty nice on starting fluid and would even idle a little on diesel whenever I had pumped the fuel up with the priming pump or pressurized the tank with air, so I am hopeful the engine will be sort of OK.

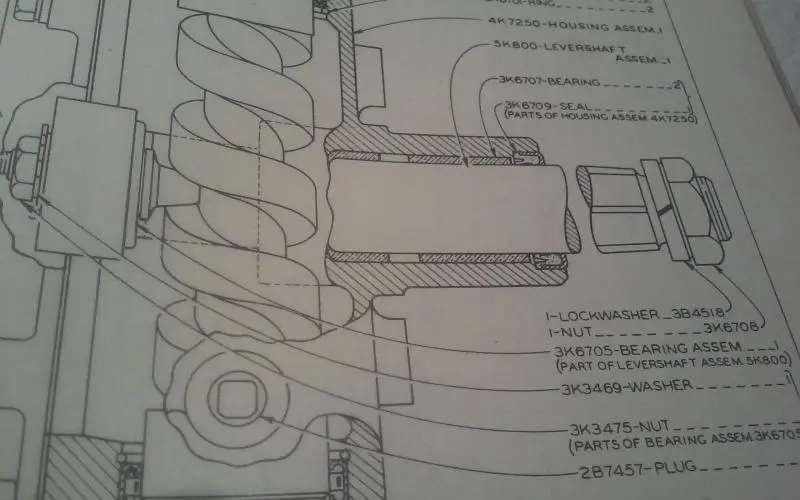

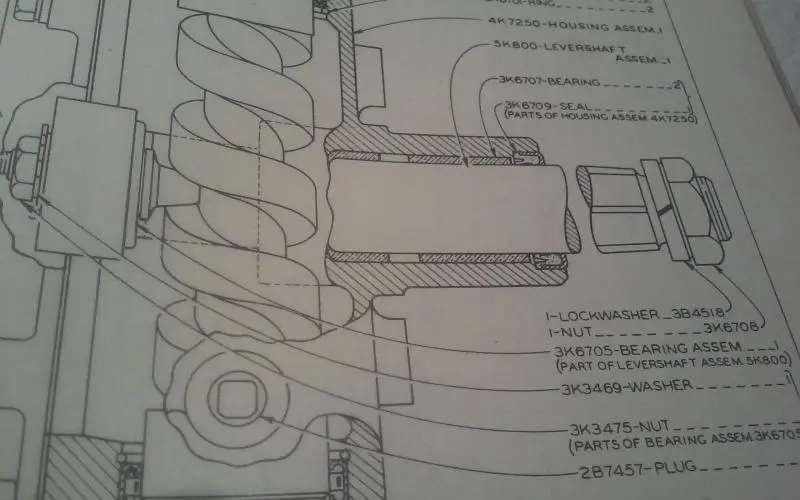

With that all on the way to being sorted out, I turned to the steering which is the reason it has been sitting so long. I went through the same steering failure on our 944 a few years ago and realized that the 922 likely had the same problem with a failed steering arm "follower" pin bearing assembly. 3K6705 is apparently still available from CAT......... for $1150-ish! NOT in the budget for this project. I was lucky enough to have had a parts 944a that I got the bearing rollers I needed for the 944 repair done previously and I was hopeful I would have enough good pieces to fix one more. Turns out the bearing in the 922 was completely rusted solid and had resulted in the tip of the finger being completely destroyed. Apparently ground into bits since I have not found any large pieces in the box. But the one remaining part of the 944 box was that shaft/finger part and it wasn't in too bad of condition, some rust and brinneling where the rollers run was the worst of it. The finger end that engages the worm gear looked very nice.

So the plan was to reassemble one good bearing using the good shaft and the rollers. I should have known the rollers were not up to the task when I had to drive the shaft out of the rusted assembly. I had put a gear puller on it after removing the adjusting nut and tried to press the shaft out with it in place in the steering box, but it wouldn't budge until I heated the arm and finally the whole bearing assembly came out of the arm. Turns out that was a good thing since everything was so rusty.

After wire brushing all the rollers and sanding the outer race and replacement shaft, I reassembled it all using a shim washer under the stock washer to get the slack out of it. It would turn with pliers but the rollers were just sliding, so I took it back apart and worked over the outer race a little more aggressively using a stone held against the race while it was spinning in a lathe. This smoothed out some more of the rust pits that formed on either side of the contact spot of each of the 12 rollers, but at the cost of increasing clearences.

Next project was to find some new rollers. First try was too big, so my idea that I would be able to recover the increased clearance from wear and cleanup did not work, at least with the bearings i had on hand. The other LM67048 bearing I had looked like it was about the same as the original rusted stock rollers. The first side stacked in so nicely that I could fit in 13 rollers instead of 12........but they wouldn't roll, just skidding. So it was back to 12 which looks bad always with an uneven spacing since this thing has no bearing cage. But it rolls easily and the rollers roll like they are supposed to! So I searched up a second bearing to get enough rollers to finish the second side and it turned out pretty nicely. I have it pressed back into the steering arm, all the rollers stacked into it (stuck in grease until the last one is put into place on each side) and adjusted so it has no obvious slack in it, but still turns easily with pliers. I took it back apart so I could pull the outer race back into the steering arm with a 3/4" bolt and a couple hard washers and a nut. It went back in a lot easier than it came out!

The steering feels fairly smooth with no power assist and rear wheels off the ground, so I am hopeful this will be a good repair for a machine that will likely see very limited hours for the foreseeable future. The shim washer I used to get the clearance down while adjusting the bearings is not hardened, but I don't expect it to wear much since this thing runs in oil and will never turn more than a few revolutions as you crank it from lock to lock. I need to check the service manual since the steering box itself has 4.5 turns of travel, but the adjustable steering stops limit it to 3 turns lock to lock. Probably cannot put that much angle in the CV joints.

D2-5J's, D6-9U's, D318 and D333 power units, 12E-99E grader, 922B & 944A wheel loaders, D330C generator set, DW20 water tanker and a bunch of Jersey cows to take care of in my spare time😄