Hi dead axle,

in a word, yes.

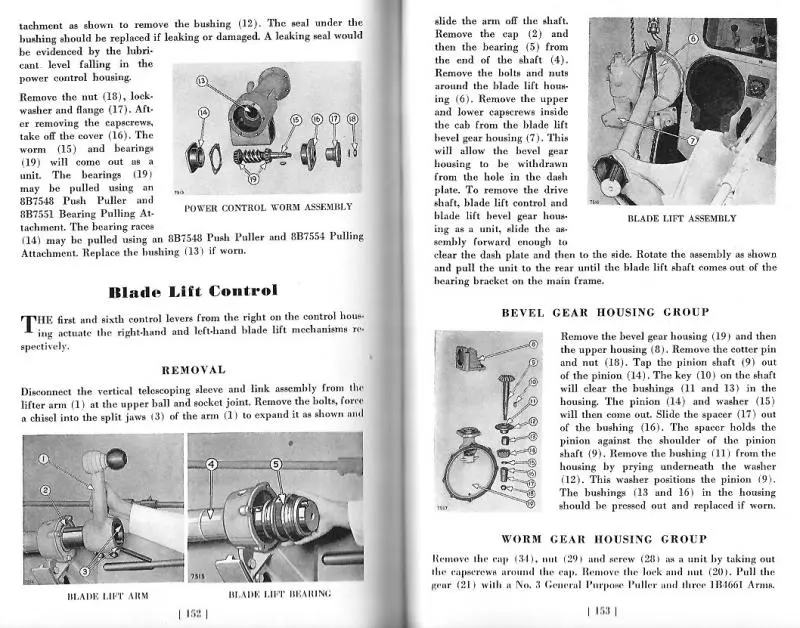

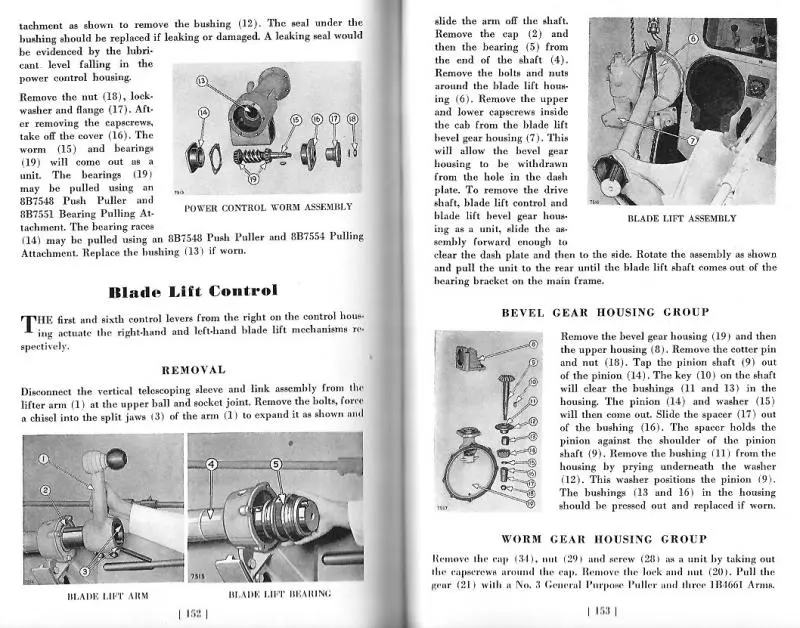

Scan from a 1943 Motor Grader SRB should be the same or similar.

Hope this helps.

Cheers,

Eddie B.

[quote="edb"]Hi dead axle,

in a word, yes.

Scan from a 1943 Motor Grader SRB should be the same or similar.

Hope this helps.

Cheers,

Eddie B.[/quote]

Thank you very much for taking the time to post those illustrations, that is very helpful! Can I ask you what publication those came out of. Thanks again for your help!

Hi Team,

publication is a small yellow Servicemen's Reference Book (SR😎 For Caterpillar Diesel No 12 Motor Grader, Form No7401-A, Dated 9-43.

This not marked with a S/No but would be for the 9K and later on for 7T Graders the same Form No 7401 but with the -C iteration (level-edition) change level.

I used this book only because the data is on one pair of facing pages.

Another later yellow SRB I have is marked for Serial No's 8T, Form No 30124-1, Dated 7-53.

In fact any Grader Book up to around the 99E has similar controls if not the same--as said above, the likely only difference is the 4 cylinder engine instead of the six and shorter blade, main frame and likely a few other items.

We used the No 12 books at the Dealer as a guide for the smaller graders as I do not recall any books being about for the smaller ones.

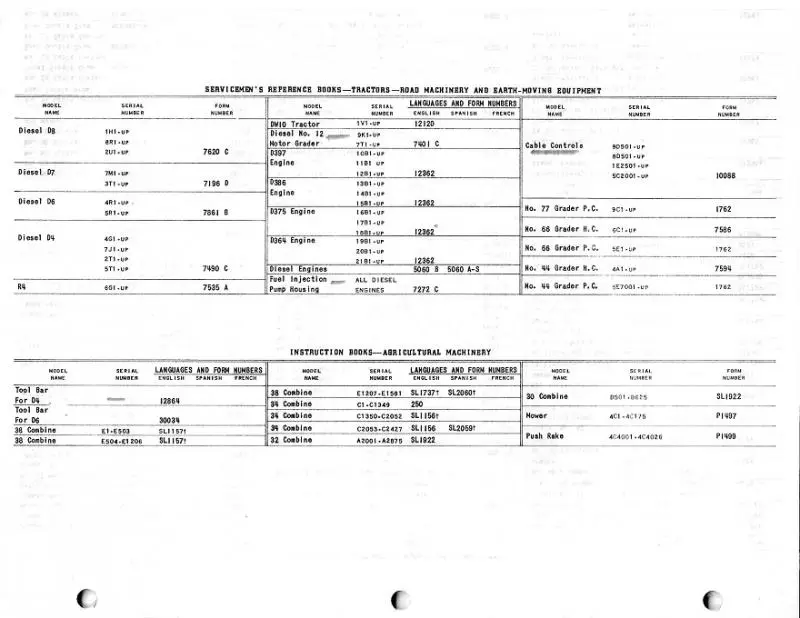

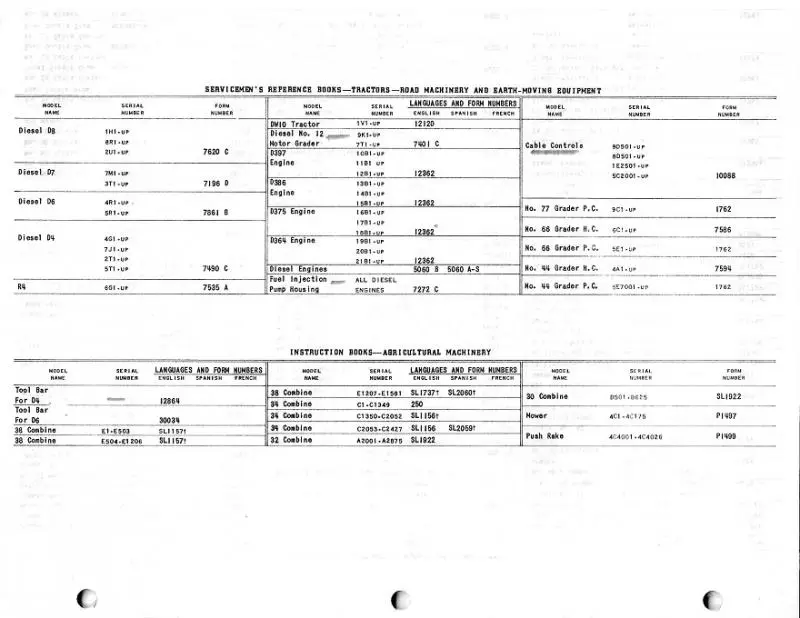

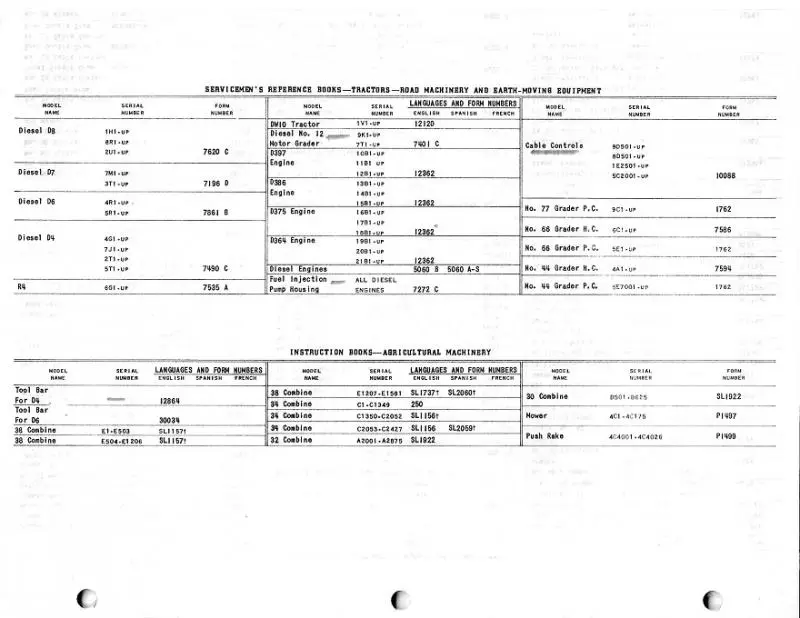

Scan below shows what Servicemen's Instruction Books were available in 1950--the latest such publication I have and saved from the trash can when i was an Apprentice at the Dealer.

Thinking back on those bent shafts, if they were bent bad enough the outer support bearing had to be oxy cut off to get the shaft out of the frame support, needed a big press and some heat, along with some heat and shrinking methods to try and true them up--likely may be too sharp of a bend in a short distance to do much with.

Cheers,

Eddie B.

You have a wonderful day. Best wishes. Deas Plant.

Hi Team,

publication is a small yellow Servicemen's Reference Book (SR😎 For Caterpillar Diesel No 12 Motor Grader, Form No7401-A, Dated 9-43.

This not marked with a S/No but would be for the 9K and later on for 7T Graders the same Form No 7401 but with the -C iteration (level-edition) change level.

I used this book only because the data is on one pair of facing pages.

Another later yellow SRB I have is marked for Serial No's 8T, Form No 30124-1, Dated 7-53.

In fact any Grader Book up to around the 99E has similar controls if not the same--as said above, the likely only difference is the 4 cylinder engine instead of the six and shorter blade, main frame and likely a few other items.

We used the No 12 books at the Dealer as a guide for the smaller graders as I do not recall any books being about for the smaller ones.

Scan below shows what Servicemen's Instruction Books were available in 1950--the latest such publication I have and saved from the trash can when i was an Apprentice at the Dealer.

Thinking back on those bent shafts, if they were bent bad enough the outer support bearing had to be oxy cut off to get the shaft out of the frame support, needed a big press and some heat, along with some heat and shrinking methods to try and true them up--likely may be too sharp of a bend in a short distance to do much with.

Cheers,

Eddie B.

[QUOTE=edb;222735]Hi Team,

publication is a small yellow Servicemen's Reference Book (SR😎 For Caterpillar Diesel No 12 Motor Grader, Form No7401-A, Dated 9-43.

This not marked with a S/No but would be for the 9K and later on for 7T Graders the same Form No 7401 but with the -C iteration (level-edition) change level.

I used this book only because the data is on one pair of facing pages.

Another later yellow SRB I have is marked for Serial No's 8T, Form No 30124-1, Dated 7-53.

In fact any Grader Book up to around the 99E has similar controls if not the same--as said above, the likely only difference is the 4 cylinder engine instead of the six and shorter blade, main frame and likely a few other items.

We used the No 12 books at the Dealer as a guide for the smaller graders as I do not recall any books being about for the smaller ones.

Scan below shows what Servicemen's Instruction Books were available in 1950--the latest such publication I have and saved from the trash can when i was an Apprentice at the Dealer.

Thinking back on those bent shafts, if they were bent bad enough the outer support bearing had to be oxy cut off to get the shaft out of the frame support, needed a big press and some heat, along with some heat and shrinking methods to try and true them up--likely may be too sharp of a bend in a short distance to do much with.

Cheers,

Eddie B.[/QUOTE

Well again Eddie I can't thank you enough for taking the time to give me this information. I was wondering if a Servicemans Reference book was even available for a model 212 as I had never seen one listed for sale. You answered my question about that! The lift shaft on mine is bent severely. It was a city owned machine and looks like someone backed into a bridge girder or something and bent it forward right at the taper. I've been conversing with someone on here about a parts machine and I'm considering a pretty lengthy drive to go and aquire some parts and just wanted to get an idea what is involved. I would also be interested in seeing what it takes to get the control unit out of one. Thanks again...

[QUOTE=edb;222735]Hi Team,

publication is a small yellow Servicemen's Reference Book (SR😎 For Caterpillar Diesel No 12 Motor Grader, Form No7401-A, Dated 9-43.

This not marked with a S/No but would be for the 9K and later on for 7T Graders the same Form No 7401 but with the -C iteration (level-edition) change level.

I used this book only because the data is on one pair of facing pages.

Another later yellow SRB I have is marked for Serial No's 8T, Form No 30124-1, Dated 7-53.

In fact any Grader Book up to around the 99E has similar controls if not the same--as said above, the likely only difference is the 4 cylinder engine instead of the six and shorter blade, main frame and likely a few other items.

We used the No 12 books at the Dealer as a guide for the smaller graders as I do not recall any books being about for the smaller ones.

Scan below shows what Servicemen's Instruction Books were available in 1950--the latest such publication I have and saved from the trash can when i was an Apprentice at the Dealer.

Thinking back on those bent shafts, if they were bent bad enough the outer support bearing had to be oxy cut off to get the shaft out of the frame support, needed a big press and some heat, along with some heat and shrinking methods to try and true them up--likely may be too sharp of a bend in a short distance to do much with.

Cheers,

Eddie B.[/QUOTE

Well again Eddie I can't thank you enough for taking the time to give me this information. I was wondering if a Servicemans Reference book was even available for a model 212 as I had never seen one listed for sale. You answered my question about that! The lift shaft on mine is bent severely. It was a city owned machine and looks like someone backed into a bridge girder or something and bent it forward right at the taper. I've been conversing with someone on here about a parts machine and I'm considering a pretty lengthy drive to go and aquire some parts and just wanted to get an idea what is involved. I would also be interested in seeing what it takes to get the control unit out of one. Thanks again...

You have a wonderful day. Best wishes. Deas Plant.

Hi, dead axle.

Personally, I think replacement would be the wise move as opposed to trying to straighten it. If it has been as severely bent as your description leads me to believe, I think it would be a pretty safe bet that there will be SERIOUS weakening of the metal in that area due to stress and trying to straighten it would only add to that. Cutting and re-welding by someone with a HEAP of clues on that sort of work might be a better option than trying to straighten it.

"A HEAP of clues"??????? I recently 'edu-mack-ay-ted' a pretty experienced heavy equipment mechanic regarding straightening bent hydraulic ram rods, thanks to an object, PRACTICAL lesson on the topic that I received 24 years ago this year with a MUCH more severely bent ram. Hell, we didn't even have a press for this 'edu-mack-ay-shun'. We used a Cat D9H ripper and some sunshine.

Just my 0.02.

[quote="Deas Plant."]Hi, dead axle.

Personally, I think replacement would be the wise move as opposed to trying to straighten it. If it has been as severely bent as your description leads me to believe, I think it would be a pretty safe bet that there will be SERIOUS weakening of the metal in that area due to stress and trying to straighten it would only add to that. Cutting and re-welding by someone with a HEAP of clues on that sort of work might be a better option than trying to straighten it.

"A HEAP of clues"??????? I recently 'edu-mack-ay-ted' a pretty experienced heavy equipment mechanic regarding straightening bent hydraulic ram rods, thanks to an object, PRACTICAL lesson on the topic that I received 24 years ago this year with a MUCH more severely bent ram. Hell, we didn't even have a press for this 'edu-mack-ay-shun'. We used a Cat D9H ripper and some sunshine.

Just my 0.02.[/quote]

Ah yes, a story I can relate to! One of my fellow mechanics at a Caterpillar oriented logging outfit ,tried to straighten a chrome rod from a 950 wheel loader lift cylinder. He had it in the press when it snapped in half and turned it into a helicopter. Scary stuff!! Back to the grader...I believe I have found parts from a donor machine to replace that lift shaft as mine is beyond getting straight again. Many thanks to the Australia contingent!!

You have a wonderful day. Best wishes. Deas Plant.