Reply to edb:

Hi Stew,

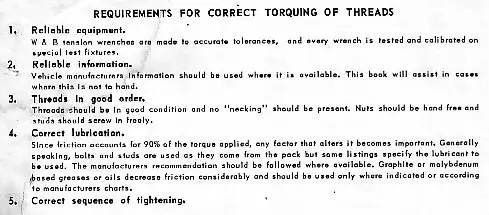

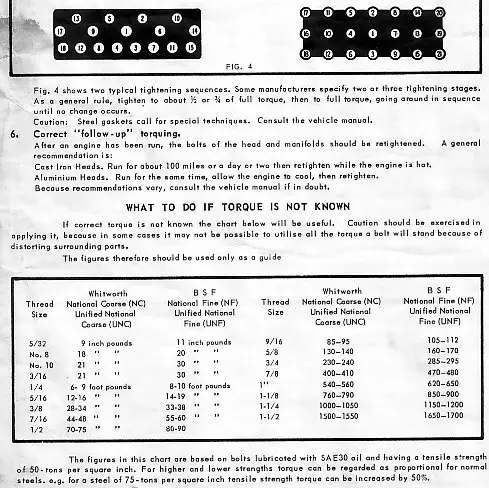

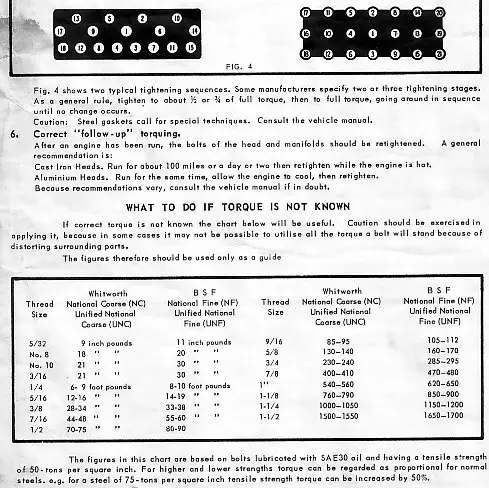

scans are from my local made Tension Wrench instruction book and gives some insight into torquing unknown fasteners.

Way back in the day of 2 Tons etc. there were likely no torque wrenches, the length of the wrench handle with a sensible steady pull/push applied gave the torque needed.

My take on this is that it should be remembered most fasteners back then would only be structural grade mild steel and with the advent of the Grading system for higher strength fasteners came the need for more precise torquing.

This explains the reason that given sized wrenches have given length handles, so to speak.

At the end of the day common sense should prevail and feeling for fastener yield/stretching, threads stripping etc. should be taken into account--err on the side of caution and use finesse to torque old stressed fasteners.

If it feels spongy at the torque you select try a lesser torque.

Hope this helps.

Cheers,

Eddie B.

[quote="edb"]Hi Stew,

scans are from my local made Tension Wrench instruction book and gives some insight into torquing unknown fasteners.

Way back in the day of 2 Tons etc. there were likely no torque wrenches, the length of the wrench handle with a sensible steady pull/push applied gave the torque needed.

My take on this is that it should be remembered most fasteners back then would only be structural grade mild steel and with the advent of the Grading system for higher strength fasteners came the need for more precise torquing.

This explains the reason that given sized wrenches have given length handles, so to speak.

At the end of the day common sense should prevail and feeling for fastener yield/stretching, threads stripping etc. should be taken into account--err on the side of caution and use finesse to torque old stressed fasteners.

If it feels spongy at the torque you select try a lesser torque.

Hope this helps.

Cheers,

Eddie B.[/quote]

That’s great Eddie b. Really appreciate that, that’s great info. Thank you