If you have enough carcass parts laying around to do a visual parts examination and they physically match up, I would interchange with no hesitation! After all, it is a learning experience!

Thank you for the reply. Hopefully I can get at the clutch this week. I have been busy with a 100 year old bank safe and the 2 Ton service manual just showed up today. Once we get the original clutch out we can compare more clutch discs. I am not optimistic there will be enough good ones. Anyone else out there had a 2 Ton clutch apart?

[attachment=60116]IMG_4945.jpg[/attachment]

Yes I have had one of those out before. That one looks like fun as the toothed ring that is in the flywheel needs to come out if you are not splitting the tractor.

I've done one, they are a nice easy tractor to work on, nothing too heavy, felt seals everywhere for simple oil control, designed for farmers to wrench on, from memory there are 3 lined plates in there, I remember I had to get mine relined and screwed up, not the first time either, not knowing the new thickness of the original clutch lining material, I ended up going too thick, and while I could get the clutch pack back together and fitted in the tractor, there wasn't enough free play room in the pack to allow for the clutch to be disengaged.

I ended up removing one of the plates, and leaving only 2 in there, it's never slipped once.

I think I have some D2 4U steering clutch plates in the shed, plus I know I have the spare main clutch plate still, I just keep forgetting to compare them.

Good luck with your 2 Ton, they are a really nice tractor, really advanced engineering at the time, wet brakes and steering clutches, single lobe cam shaft, overhead valves, the same oil used right through the tractor, they were sold in big numbers here in Oz in 1927 and 1928.

Mike

Hi Team,

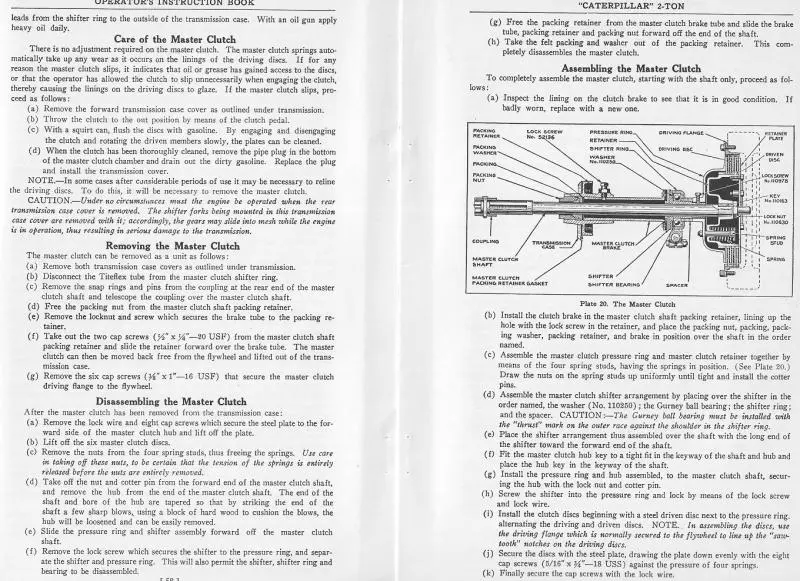

scan below from the grey 2 Ton Operator's Instruction Book, Form No 4024.

Hope it helps--repeats what has been said above.

Cheers,

Eddie B.

Thank you for the replies. The service manual certainly helped to understand the clutch removal. Pretty nice set up as once the transmission shaft coupling is removed there is enough room to slide the complete clutch and shaft assembly back to remove it. The clutch assembly is now out. Of coarse the clutch plates, inner toothed ring, and the outer toothed ring were very rusty and made us earn our progress. We also had to remove the clutch pedal throw out bearing shaft because with the clutch assembly being frozen solid we could not tip the transmission shaft up enough to clear it. Normally there would be enough give in the teeth of the disks and toothed ring

to lift up the rear. Naturally one half round key would not budge from the key way on the shaft. We had to use every trick in the book, some old ones from my uncles and a few modern high tech ones from me to finally prevail. The toothed outer ring that bolts to the flywheel gave first. Once out that ring was persuaded to leave the clutch linings.

Funny thing is, this cat must have been been parked with a stick on the clutch before my uncle bought it. It was all rusted in place with the clutch springs compressed. Fortunately, we have a spare clutch from the parts cat that is in pretty good condition. The disks are shot though. I forgot to take pictures. I'll take a few next time.

Finally got around to comparing the clutch plates, the D2 4U steering clutch plate is smaller than the 2 Ton plate, plus as you can see, the teeth are completely different.

When I had my 2 Ton plates relined they were too thick, because I didn't have the original thickness spec, the linings on mine are around 0.155" thick each side, I've got a feeling the new spec was actually 1/8", someone here can confirm that I'm sure.

Mike

Hi Mike,

Great work on the 7J, i would say you will have it ploughing the padocks very soon.

Have you tried the 2 Ton plate up against one off a D4 as they are bigger.

Regards

Finally got around to comparing the clutch plates, the D2 4U steering clutch plate is smaller than the 2 Ton plate, plus as you can see, the teeth are completely different.

When I had my 2 Ton plates relined they were too thick, because I didn't have the original thickness spec, the linings on mine are around 0.155" thick each side, I've got a feeling the new spec was actually 1/8", someone here can confirm that I'm sure.

Mike