Sounds more like internal transmission issues to me. Not unusual to see some oil squirting from the trans with cover off between shifts but should not do that after a gear is selected.

It squirts oil out continually, so much that it coats the top cover of the transmission. When the tractor is first started, no squirting oil is visible, then after shifting to a gear, the oil starts squirting and it doesn't stop.

That to me indicates you have transmission clutch piston sealing issues.

I went back out last night and started the Cat up and went through all gears at WOT with brake on hard. After giving time for the oil to circulate through the transmission, the oil only squirted for about 2 seconds when I switched gears, it stopped after 2 seconds in each gear. I did this for about 30 minutes and it never changed, but my pressure was still low, around 200 psi. I am considering getting another transmission pump to see if the one I bought was defective because it seemed to have a little slack in it when the pump was dry. At this point I am probably grasping at straws, but there is a cause and there is a solution. I just have to find it.

Good chance that could be the problem if the pump came from the "land of almost right". Should detect little to no axial movement on a new pump.

Hi Team,

the plug in the valve body you refer to would be removed to test what Cat calls "Initial Pressure" of the Direction Clutch Modulating Relief Valve (MRV)

Initial pressure is when the Modulation Relief Valve load piston stays back in the relaxed position.

This low pressure, usually around 40 PSI, is so the clutch engages softly and then as oil is fed in behind the MRV Load Piston the MRV spring is compressed at a fixed rate of pressure rise to its set maximum pressure.

The MRV load piston oil is supplied thru an orifice in a floating check valve so it can dump the oil trapped behind the load piston quickly ready for the next clutch engagement where the process of modulated clutch pressure rise starts again.

If the load piston or its check valve are sticky or there is crud floating in the system that can periodically block/restrict oil flow thru the check valve orifice or the load piston leaks more oil than can flow thru the orifice then the low pressure you see may occur--I stand to be corrected as it is some 35 + years since working on these things.

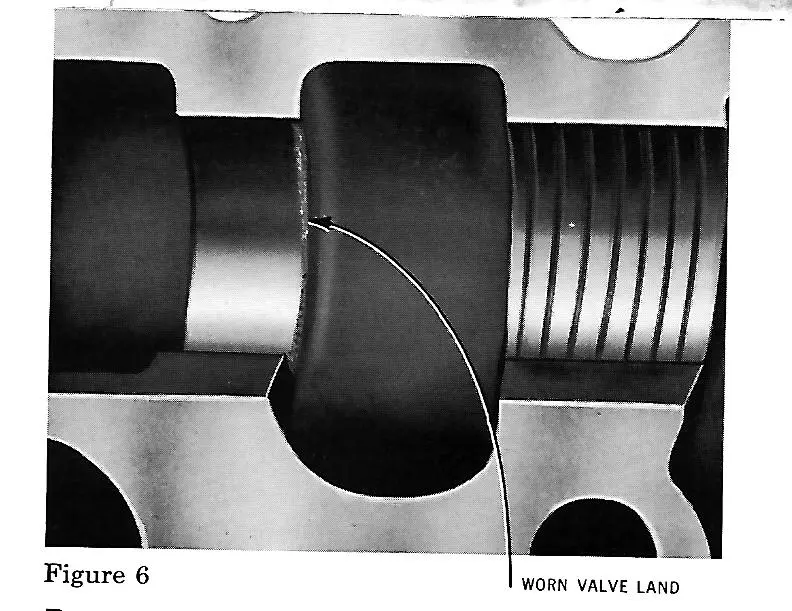

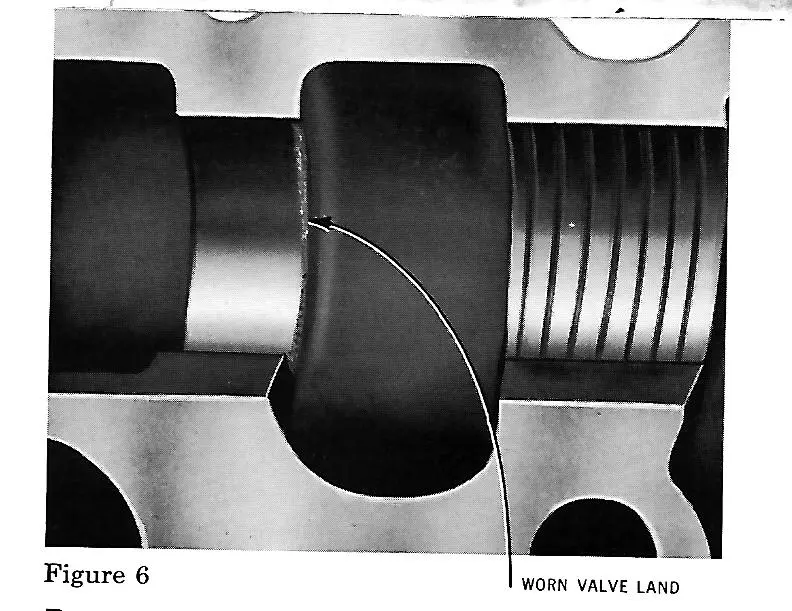

From memory at least one erosion wear point to check is the valve body land that aligns to the rear face of the MRV load piston when it is in the compressed position as dirty oil will scour this land away and I guess if enough is scoured away then the load piston will not full travel to achieve full valve set pressure--a similar erosion takes place on the valve body relief land for the working end of the MRV. really need a Parts Book to be able to describe the position of these lands clearly, I do not have literature for these later machines.

The grey sand blasted wear lines/tracks to the sharp edges of lands would be evident as you look in thru the ports on a dismantled valve group.

We often had to discard such erosion worn bodies due to excessive leakage issues.

Cheers,

Eddie B.

I would think a drop from 300 psi to 200 psi when the oil warms up is more related to pump condition than control issues.

The conditions seem to vary, first you say pressure dropped to about 50 psi but later state holding 200psi. Could be there is both a control and pump issue.

[quote="Old Magnet"]I would think a drop from 300 psi to 200 psi when the oil warms up is more related to pump condition than control issues.

The conditions seem to vary, first you say pressure dropped to about 50 psi but later state holding 200psi. Could be there is both a control and pump issue.[/quote]

Yes, there very well could be both involved. I did a test this morning on the machine with this result:

On startup and during the test I never touched either brake pedal or engaged in any gear. This takes the transmission mainly out of the picture except the 40 psi lubricating oil through transmission.

Let idle (throttle between the "o" and the "v" in the word "governor") for 30 minutes - pressure held a steady 295 psi the entire time from startup to 30 minutes. There was no oil squirting or visible in the test port.

30 minutes into test, the throttle put to "e" on the word "governor" - pressure held 295 for 5 minutes and then started dropping. There was no oil squirting or visible in the test port.

After 10 minutes the pressure was 260. After 15 minutes the pressure was 225.

Throttle put to WOT 48 minutes into test, pressure was at 210 50 minutes into the test when I throttled it down and idled it before stopping the engine. When I went to idle, the pressure dropped to 190 psi.

Probably going to order another pump this week and try that avenue again. What is the definition of insanity again?:confused2:

Your positive the springs were good in the control valve and modulating relief valve?