Hello everyone,

New to the group and to dozers. Picked up a '66 D6C a few months back and have been running it hard - loving it. Been clearing land and the machine has been bulletproof until two days ago. SN 96AXXX

The Problem:

Forward and reverse work fine

Cannot get neutral - shifter won't move far enough back

Only way to stop is to shut it down

With engine off, I can pull the shifter back and feel it ratcheting/clicking on something, but it springs forward when released

Still won't engage neutral

Machine Details:

Powershift transmission

Unknown service history (got it used)

Just pulled the seat and cover plate - absolutely filthy under there, lots of debris

What I've Done:

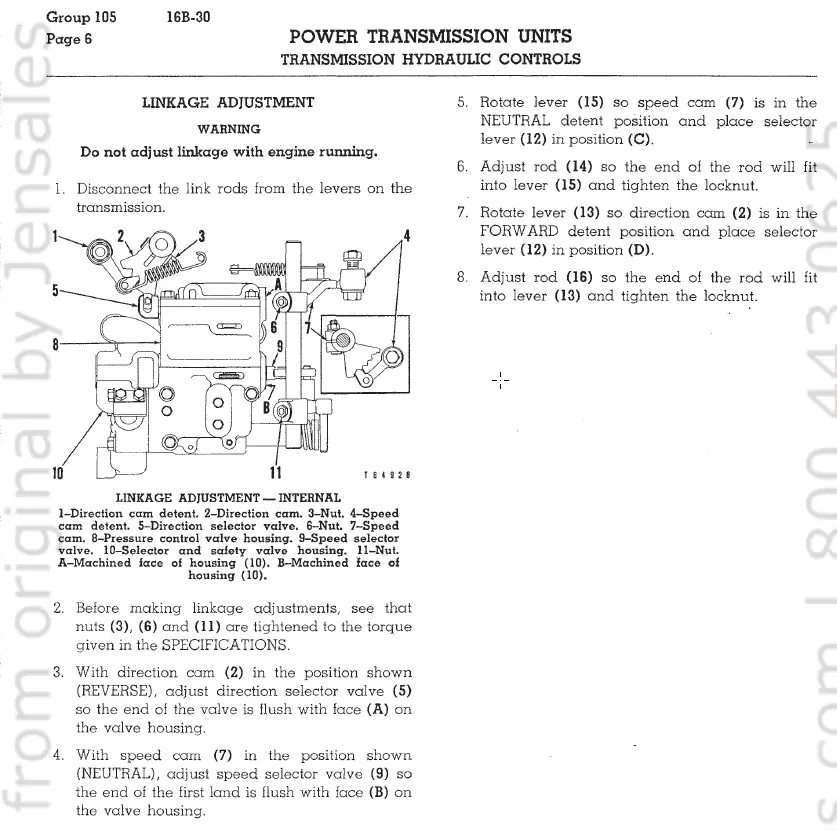

Read up on internal linkage adjustment procedures

Cleaned out the debris

Based on how it feels, seems like the selector needs to move just a hair farther to catch neutral

My Theory: Given the condition under there and the fact it almost gets to neutral, I'm thinking the internal linkage needs adjustment. But this is my first dozer and I'm not a pro mechanic.

Questions:

Does this sound like linkage adjustment, or should I be looking elsewhere?

Anyone experienced this specific symptom before?

Anything else I should check before pulling the cover?

I know getting into the linkage is going to be a job (and probably involve drilling out some broken bolts), so want to make sure I'm barking up the right tree first.

Thanks in advance for any guidance

I have attached the linkage adjustment instructions I was planning on using.

1966 D6C

1966 D6C

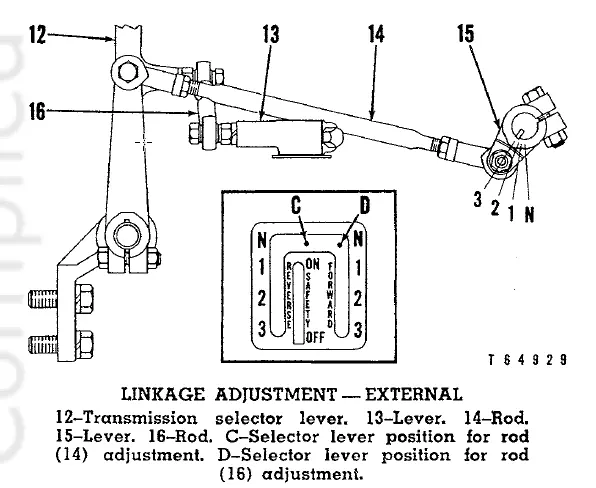

Yes, check adjustments. Do the external adjustments first (missing in your instruction post)

Thank you OM!

This is the extrnal view that was referenced in the previous attached pic:

1966 D6C

Thank you again for confirming what I suspected OM. I cleaned of the area and soaked everything in PB Blaster for over 24 hours, I am hoping the fastners come off without incident. Given the number I have to remove the odds are at least one will give me issues.

I will let you know how it goes!

1966 D6C

Hi, Jprice1101.

Does your powershift control lever have much 'loose' movement when it is in any of the gear-engaged positions?

That is an older machine with a good few joints in that linkage - may be worn to the point where there is too much slack in the linkage itself to be able the get back into neutral.

Just my 0.02.

You have a wonderful day. Best wishes. Deas Plant.

Thank you both for sharing your thoughts and insight.

DP - I was thinking the along the same lines... it does have a little movement when it was working and in gear, but not much. The control lever is a bit worn at the top where it slides in the selector channels. It will need some attention soon, it is below 1/4". But that is a project for another day.

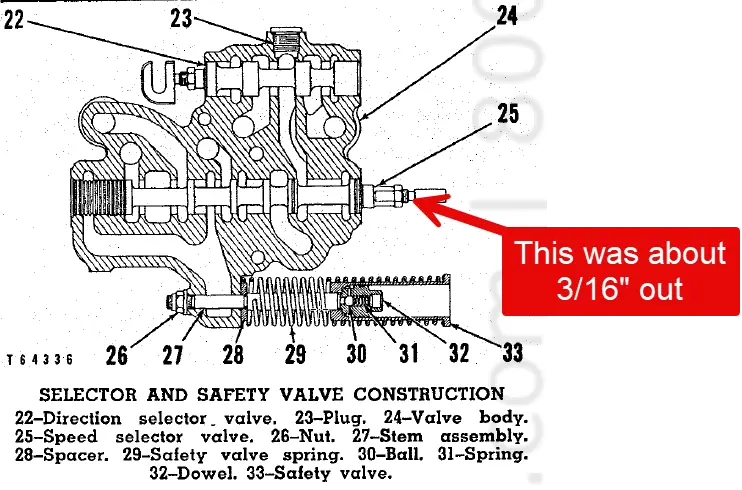

Update - Surprisingly all the nuts came off the cover on the transmission without breaking. Looks like them being covered in oil kept them from rusting in place. There was an issue when I got to step seven on the adjustment procedure. The retaining nut on the speed selector valve was loose. I could turn the valve with just my fingers. The "first landing" they describe in the procedure was out of the valve body about 3/16". I do have a cross-section view of the valve body, but I do not know which paths control what action. I have included the cross section view that I am referring to. I am hoping that with this valve back in place it will be back to operating correctly. I have to do some clean up on all the parts I removed and the mating surfaces before I am able to test it out.

1966 D6C

Hi, Jprice1101.

I'm no 'ex-spurt' but I suspect that that 3/16" might be the problem.

Just my 0.02.

You have a wonderful day. Best wishes. Deas Plant.

Hello again!

DP, I am no expert either, but it was pretty apparent that it wasn't right!

Update:

I made the adjustments to both the internal and external linkage. I got everything sealed back up and all the covers torqued down. I then crossed my fingers and fired it up. Everything functioned properly!!

As a matter of fact, the shifting is better than it ever has been. It now has really positive "clicks" when shifting between the gears and moves much smoother with less force. I even have all three gears, both forward and reverse. Previously there were only two gears available each way. The prior owner said when I bought it from him that third gear wasn't used, and he didn't think it was working correctly. Although I do agree that I will rarely if ever have a need to go that quick it is nice to have it functioning properly.

Having that sorted out is a huge relief. Now that I have spent some time under those panels and the seat, I have a new list of "to do's." First is going to be getting all the sticks and dirt scrapped off and cleaned up; it is a real mess. I don't like working on things that are caked with grease and grim.

Next, I am going to update the wiring. There was a ground wire under the seat that is being held on by a pair of vice grips. I can understand getting something working long enough to get it moved to a better area, but these have been there for a very long time. (On the plus side I do have another set of vice grips now!) I am not even sure if that wire connects to anything. It looks like some "modifications" have been made over the years. The original wiring conduit is still there, but some of the wires go to nothing. And there are other wires held in place with zip ties, and others with electrical tape covering the splices. None of this is surprising to me seeing that the machine is almost 60 years old, but I think I can do a little better. I am going to replace all the gauges in the process. I have the wiring diagram and it only has a handful of wires, so it shouldn't be to bad.

I did have another question: The blade has a power tilt and can manually be pivoted to make it angled either to the right or left. All of this works well enough. It would be nice if the hydraulics would hold the blade in position, but it slowly bleeds down, not fast just enough that some adjusting has to be done wen pushing a long distance. This has nothing to do with my question...under the arm that holds the blade (I think it is called a C-arm) there are a few brackets that are below this arm close to the ground. In my research I think these were for some sort of wear shoe maybe? Is this correct? If they are what do these look like, could they be fabricated or is there a place that sells them? If they are wear pads that support the blade and limit the amount of digging it will do and keep the blade at the same height I would be interested in learning more about them. Any insight would be greatly appreciated. I will get some pictures of the brackets today and post them later on.

Thanks again for all the advice!

1966 D6C

Congratulations! Sounds like a work in progress; plenty of excitement whether using the machine or just tidying things up. Glad that you got the shifting figured out. Is there a remote chance the original owner had purposly set the shifter to not use third for safety reasons? I mention locking out of gears on orchard machines is why I ask.

If you are referring to what I consider "training wheels" (the skids behind the blade). They seem to be a normal thing on a D2 or D4 machine. I do not have any on my D5 or D6's here.

Have fun with your new toy. JM

jm - If these are "training wheels" I may need to get me some, any ideas on where to get some? Could I possibly fabricate them?

I would guess that the ones for the D2 or D4 overall design would be the same, they would just need to be larger for the D6. I have checked in the part books I have and these are not referenced in the. Does anyone have any pictures or drawings of these item?

Here are the pictures I was refering to above.

1966 D6C