4F6979 crosses to the 4F6980, used in a variety of generator groups, for both the 6V and 24V.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

We’re doing a engine swap on our D47U by taking a good 315 power unit that came out of a Bucyrus-Erie shovel.

I’m going to use the 40amp generator like you show.

When pulling apart I noticed the different gear diameters.

[attachment=68414]98750B00-96F2-4410-9267-F7DEE344B5DF.jpeg[/attachment][attachment=68415]D53628F5-8406-421C-ACD7-B2AE1986D1B3.jpeg[/attachment][attachment=68416]D7D93BDD-A541-42EC-9412-9B7E9E841DCA.jpeg[/attachment]

It appears that, depending on which generator you have, you can run both the 24V or 6V generators with the small 19t gear and 17T idler and the 4F6979-4F6980 housing, or run the 6V generator with the larger 26T gear and the 4F6978 housing, no idler.

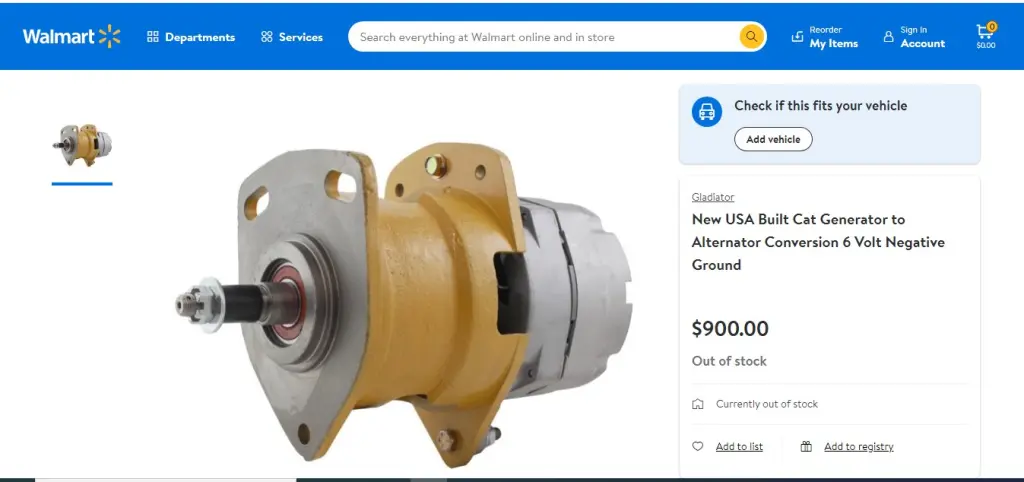

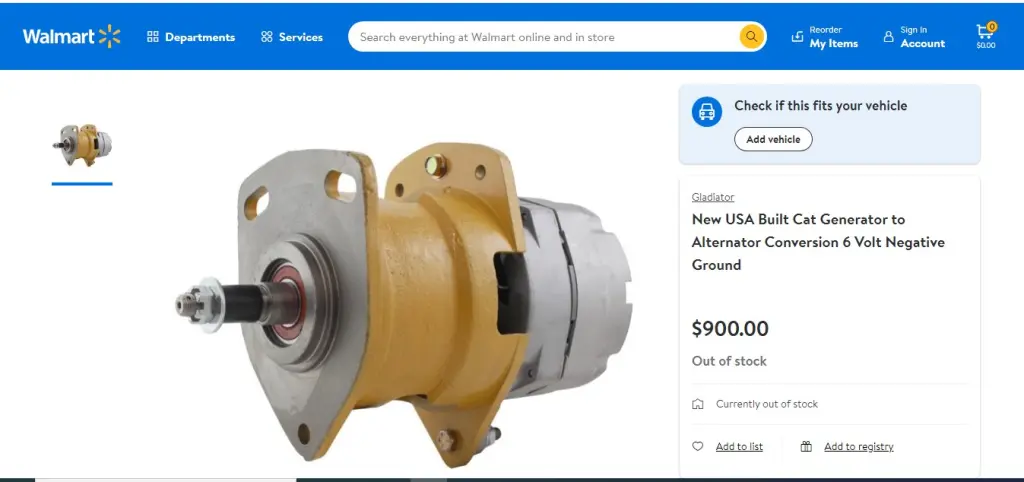

Thanks for all of the info. Today I found out that the 6V American Bosch still works. I don't have the heart to chop up a working generator and finding 12 or 24V fields seems to be an issue, so on the shelf it goes for a future project. I am now beating the bushes for a dead core to cut down and mount an alternator to. My other D6 has a alternator mounted to the top of the generator with a belt drive. It works well. My plan is to build my own version of the $900.00 mount as sold by Walmart. I plan to use a Love Joy coupling. The alternator will get a new fan blowing the correct direction. The pulley will be replaced with a spacer and the nut will be replaced with a love joy that will have two flats milled so a wrench will fit and the center threaded match the alternator. I plan to shorten the generator body and reinstall the rear cover with the shaft exposed. Reason being is I want bearings on each end of the driven shaft to provide support for the gear to prevent linear and axial thrust alignment issues under load. I will work out the fine points just as soon as I get a core apart on the bench.

Good on you for choosing not to butcher a good working component. I kept the 6v 18a generator on my D2 and use an electronic regulator and an Optima battery. Works great. I see though that GM one-wire alternators can be configured for 6v negative or positive ground. Really is quite the versatile component and dirt cheap

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality