Lots of Youtube videos....some good, some not so much, but should get you started

Lots of Youtube videos....some good, some not so much, but should get you started. Some of the best are on a channel posted by squatch253. He posts here as Sasquatch. One is starting a D2 which is very similar to your grader in every respect. He explains some of what is going to happen before he does things.

Things to check before starting

Pony motor oil not diluted with gas or coolant. Best to drain it and refill.....only takes about 1 1/2 quarts drain spigot is on rear surface of the main clutch housing on the left side of the machine.

Other pint of oil in the pony air breather. Might take close to a gallon in the diesel engine air breather. Clean used motor oil is fine for these cups if you want to save a little

Oil level in the pony pinion gear/clutch compartment.... plug to check it right there on the side near the clutch lever....motor oil is fine in there. This is important because the whole pony motor timing gear and pinion drive train is lubricated from that sump.

Oil level in the diesel injection pump housing....again motor oil is specified....fill to level of plug on side

Drain any accumulated fluids from pony cylinders through petcocks on bottom of the heads...this can also be used to clear it if you flood the engine.

Check coolant in diesel radiator and bleed any trapped air from the pony through a small petcock on the water return elbow above and inboard of the decompression lever.

Pull decompression lever out pointing away from engine to decompress the diesel to make it easier for the pony to get it rolling.

Pony mag switch on,

gasoline valve on. This may be on the control side of the engine or may be a valve on opposite side under gas tank outlet/sediment bowl or possibly both. Pony tanks are notoriously prone to rusting inside and can be so bad the outlet spigot/valve above the sediment bowl is clogged.

choke control is black knob on left, pull it out to apply choke.

Pony throttle is on right... pull it out to idle the pony for initial starting attempt. A properly functioning pony will usually start best at idle setting. As you push it in you simply allow the belt drive governor to have more throttle travel and ability to run the pony up to speed and respond to load.

Its a good idea to manually move the throttle to governor arm linkage and make sure its moving freely. It should feel a little spring loaded in the decelerate direction but mainly just needs to move back and forth freely.

Also a good time to make sure governor pulley and water pump pulley both spin freely and roll the pony through a couple turns

Make sure grader transmission is in neutral before starting and diesel throttle is closed.

Check gear lube in small gearbox under the floor where the powershaft from the transmission turns up to the PCU with all the control levers. Also look in the small hinged door on the cover of the vertical shaft. There should be a special soft shear pin through a shear flange in there and a place for a couple of spares. This should not be a bolt, but a pin. A bolt may allow you to snap the drive shaft if you still have some control clutches in good shape.

Most old graders have well worn dog clutches on the various levers of the PCU. Good knobs and a pair of gloves help but do not usually totally mitigate the "knuckle buster" quality of the controls. You want to aggressively push or pull the levers in or out of engagement. There is no "feathering" those dog clutches.

One option you may want to consider is pull or push starting the diesel engine and just bypass the pony all together if it won't cooperate! On good ground it will not be too hard to start it but the grader is heavy and may require more than a pickup etc to get it rolling. Steering is slow and it is always easier to work in straight lines pulling and pushing unless you have plenty of room. If it is in decent shape it should start within a few yards, but sometimes it is hard to find the right gear etc the first time out of the gate. If you are in reverse and moving forward or vice versa, you will know about it because the oil in the diesel air cleaner will puke out the top! If you persist in pulling or pushing with the transmission in the wrong gear, the engine can even start and run backwards (not all that badly in my experience!). You will quickly notice the oil and exhaust coming out the air intake, simply close the throttle to stop the engine, select the correct gear and go again.....no harm done usually.

Good luck!

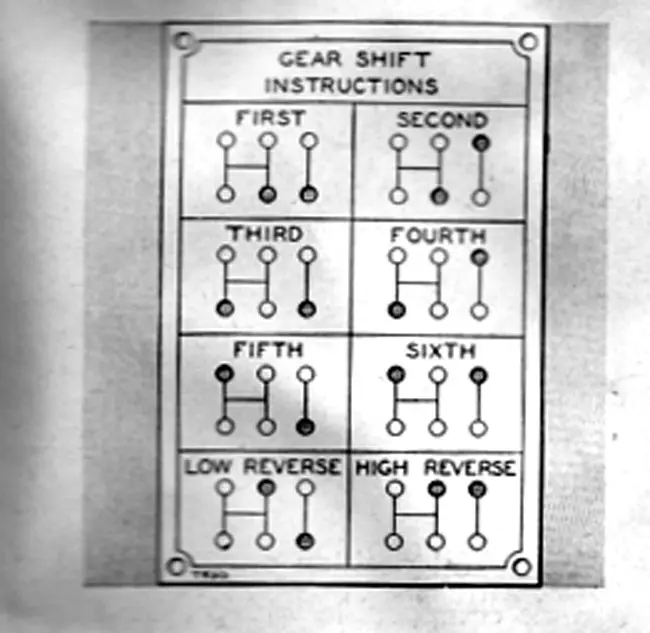

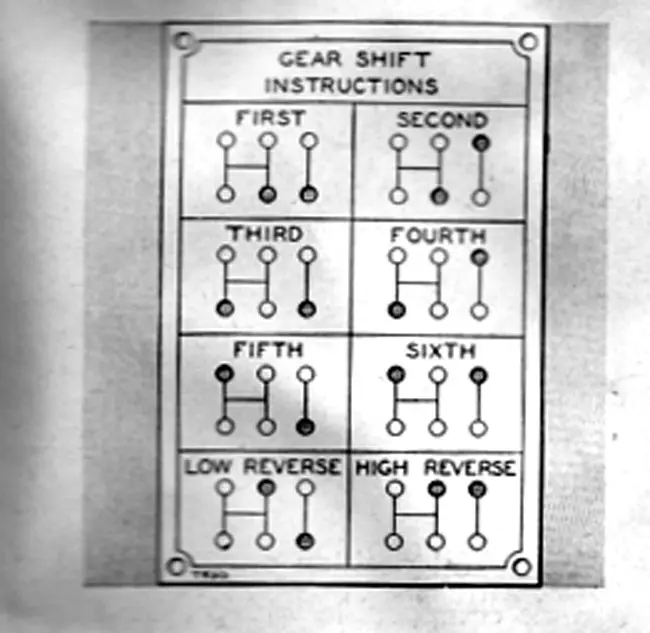

Jersy,great post. May I add, my shift pattern chart was un readable. Stick to the right and forward is reverse. Stick to the right and back is first forward. Solid stick far right is 2 speed. Back is low, forward is high. Good idea about towing because lots of problems can be in the pony. Do yourself a favor and get new fuel filters if it hasn't run in over a year.. Clean out the fuel tower and replace the filters first. I have a shop vac and a small 110 generator. I put it on blow and stuff the hose in fuel filler opening with rags. It has lots of volume with not much pressure. Gives enough pressure to push fuel up through fuel tower and injector pump. Check for gunk in the fuel tank by opening the fuel drain valve under the cab. Lots of luck.

my shift patter plate it hard to read as well. it was made of steel and not brass so it rusted easy.

Really appreciate all the help! Got it hauled home and and unloaded this morning now I’ll get to put all your advice to work!

Clean looking machine. Is it an optical illusion or does the rear drive tire look larger than the front drive tire? Or maybe the angle the picture was taken.