Camaroman, I think it is possible, if you can get it off the main would be a lot nicer to work on a bench, they are heavy to lift by hand but definitely possible to do, careful of gear hanging out the bottom of pony block, also make sure you remove all the bolts/nuts between the main and pony block, yes there is a few hidden in the gap. triple check with a torch after you clean the area for them, they lay in wait to break the pony block casting.

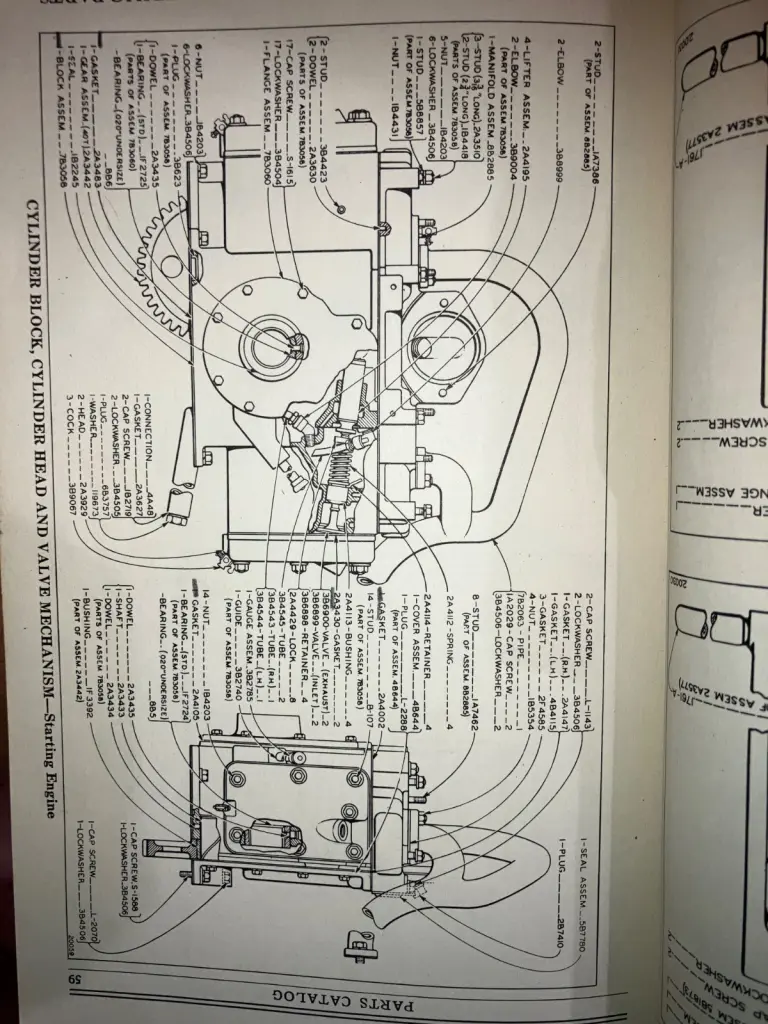

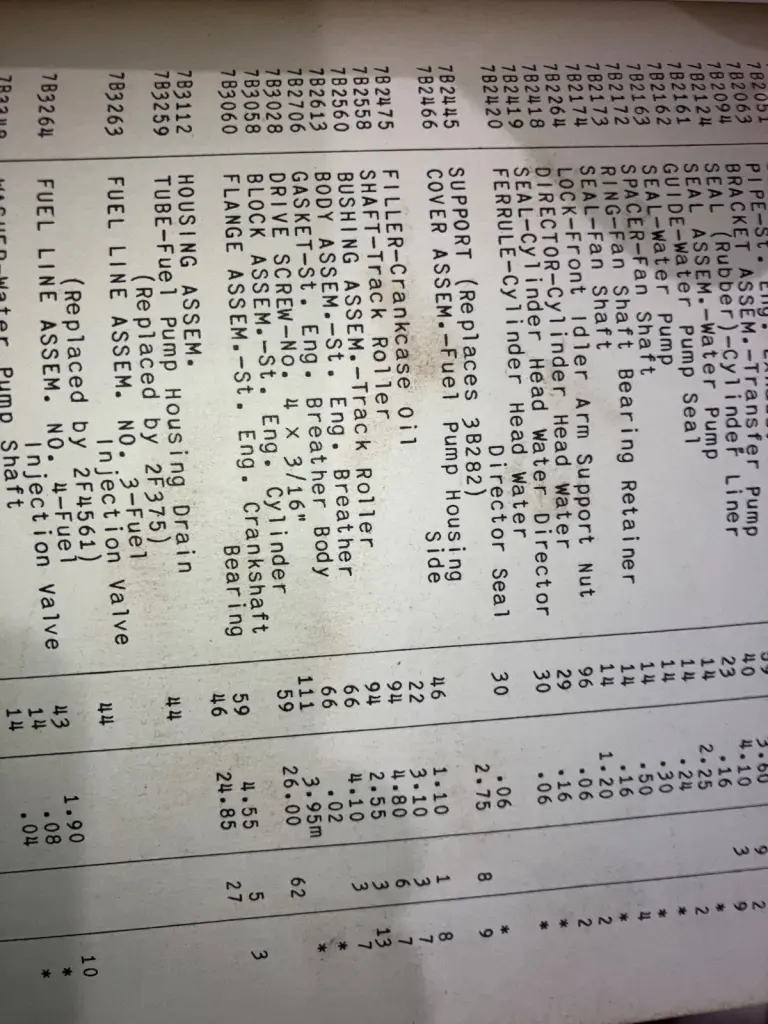

From Form 8480 “Parts Section Diesel D4 Tractor For machines 7J6753 to 7J9999 inclusive and 2T1 & UP”, published March 1944.

From attachments 7B3058 Block Assembly weighs 62 lbs (1944 cost $26.00), and Manifold Assembly 8B2885 weighs 22 lbs (1944 cost $12.60).

I think those are your heaviest items to approximate from, totaling 84 lbs minimum. The Starting Engine can be lifted by hand with all the other “stuff”, but it’s an awkward lift and high risk for damaging, in my opinion.

Keep working safely-

Maybe check the magneto drive gear

yes thanks - i do own a marine engine repair shop so used to working in tight spaces and I have all kinds of variations of the trusted 9/16 and 1/2 sockets 😊

All good - as it is the Lords day of rest I will be pulling into this this week as im taking a week or two off from work anyway to tinker on my new to me toy 😊

Prob tear into the pony monday. I did get the carb out and did an extensive clenaing incl drilling out the lead plug and clearing the pilot channel as it was 100% blocked with crud. Also sanded down a float from a quadrajet and drove the original bracket into the foam- and also matched a rubber tipped needle (they seal much better than the old metal ones imo) - hack job but zero fuel leaks past the needle (i will still use a manual shut off valve) but the carb did come out nice.

Also noticed the starter making some awful grinding noises so will be checking everything out.

Another forum member noted the oil could be leaking past crank seal into clutch area so I might as well pull the whole unit and do a farmers "thorough" going through so i can reliably crank the main engine over without worrying.

I do have an oem parts book on the way and a pdf version of the workshop manual - thanks!

Bummer on your pony motor. One step forward and sometimes a few back...If it was mine, first thing I would do is remove the 1/2" plug at the front cover and shine a good light and look at the mag gear as the previous poster pointed out. Sometimes it can just be a chipped tooth making it bind. I am bit of a lazy person at times, so try the easy stuff first; rock the pulley back and forth by hand and look at the movement. If it sounded like running on one hole and loss of power I would tend to think you would hear some popping if you lost a valve.

I hate to think that you stuck one piston by overheating that pony; I would remove the heads and most likely the cooling ports are plugged with crud. The D2 and D4 ponies do not have a water pump, so the main has to be spinning to circulate water throughout the system.

Crossing my fingers that it is just something simple! JM

I did rock the fw back and forth at one point it was stuck then I managed to turn it almost a full revolution.. I had no idea about the mag tooth thing so will check. Yes hopefully sth small but after watching laol and seeing the amount of crud I would at least pull both heads to verify they aren't plugged.

So if the clutch housing is full of oil due to a bad crank seal prob take care of that too as that wd ruin the pony no oil. I wonder if oil contaminated clutch would slip and cause the loss of power..

My first dozer so not quite familiar with all the systems just yet

I had oil loss and one postermentionedit can drain back into clutch housing which could explain where mine all went in a weeks of short runs.

You might be able to pull that 1/2" plug without removing anything besides the hood. Oil can be lost via the pinion clutch housing, that big O ring can be a bugger to deal with.

No pressure from here, we all get to educate ourselves on this old iron!

Good luck. JM

Which plug is that? Hood is off. U mean to check pinion oil level? Sorry I'm barely beginning to know the names ..

I know the pinion housing takes oil. I did notice the main lever to turn main would not stay in place. I do not know how to use these things I kept having to hold it in place to spin main..

Hopefully I didn't toss sth up.. I did watch some videos before and made sure to pull the sma engage lever but could not feel anything so just proceeded to use large lever manually