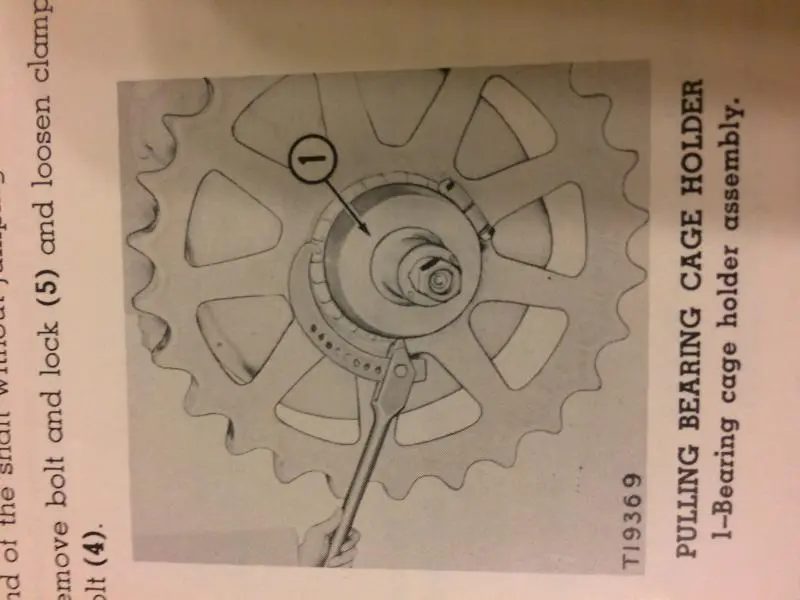

Yeah,had that in the D-7-17-A I had purchased,it seemed to do the job,however previous owners failed to keep those rear bearings tight,resulting in the cages becoming stripped of their threads,found this when it was it was dis-assembled ,firstly try and tighten

the rear cages,they never seem to be over-tightened,[always loose]. my opinion,again

leon

Very good advice to tighten the rear bearing hubs.

My 17A leaked quite badly on one side so I took the time to loosen the hub nut with a home made socket welded to a 12 foot bar then tightened the hub as per the book - which was quite loose. No oil has leaked since.

It's a bit of a job but worth trying. I would not be keen to add thick oil which will likely have poor lubricating qualities.

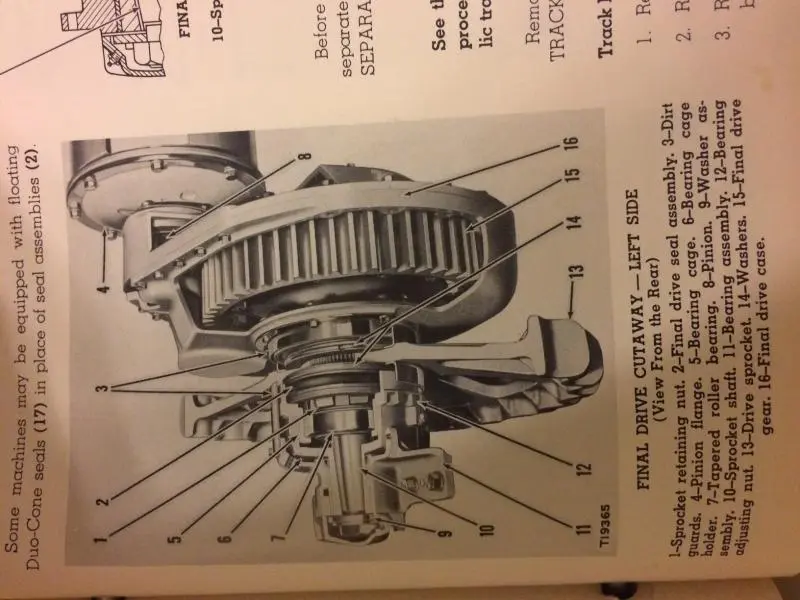

The large nut that requires the special wrench.

You should check the retaining smaller nut for tightness. I loosened mine to be sure the assembly was properly located, then tightened with a long bar.

The large castellated adjusting nut does require a special tool, but I have used chain with a long bar to make the adjustment. A bit crude I know but it works tho it takes a bit of fiddling to wrap the chain around the hub and engage it with a bar. Others might used a pry bar and a jack to lever the hub around or a cold chisel. I don't favour that method as the keys usually bust off.

The hub should be loosened before tightening counter clockwise.