There is only one pump that supplies circulating oil to the main clutch and the booster and runs continuously. A pressure relief valve limits the pressure to 350 psi. I would expect to see full pressure to the supply side of the booster whether the clutch is disensgaged or not.

Hi Team,

as OM says the system is limited to 350 +/- 10 PSI by a relief valve.

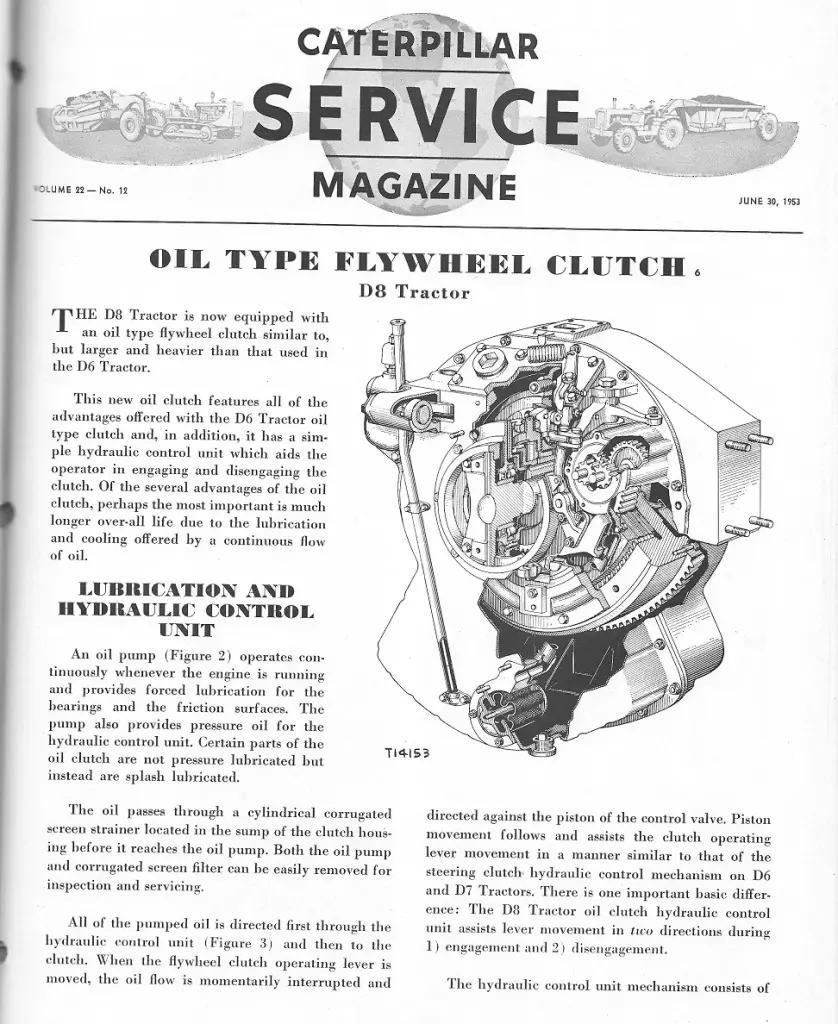

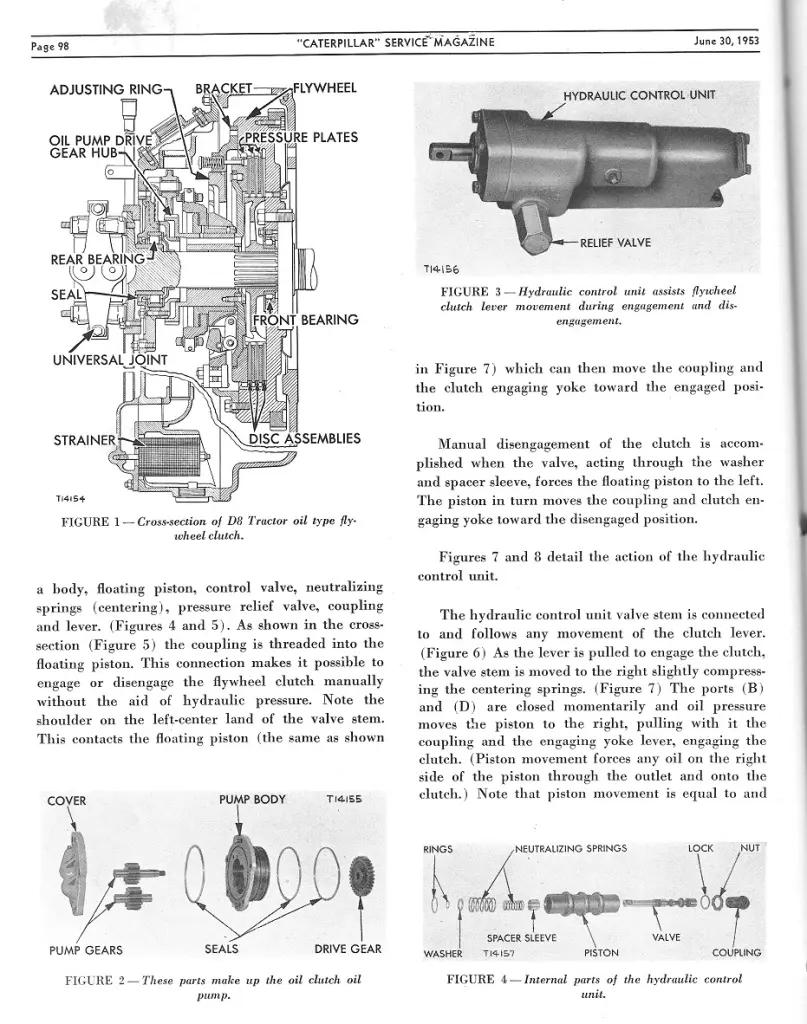

The oil pump supplies oil for clutch lubrication and cooling at low pressure as well as up to the set pressure whenever the clutch lever is moved back to engage the clutch and/or is held there--you would likely build to full RV (Relief Valve) pressure in this mode.

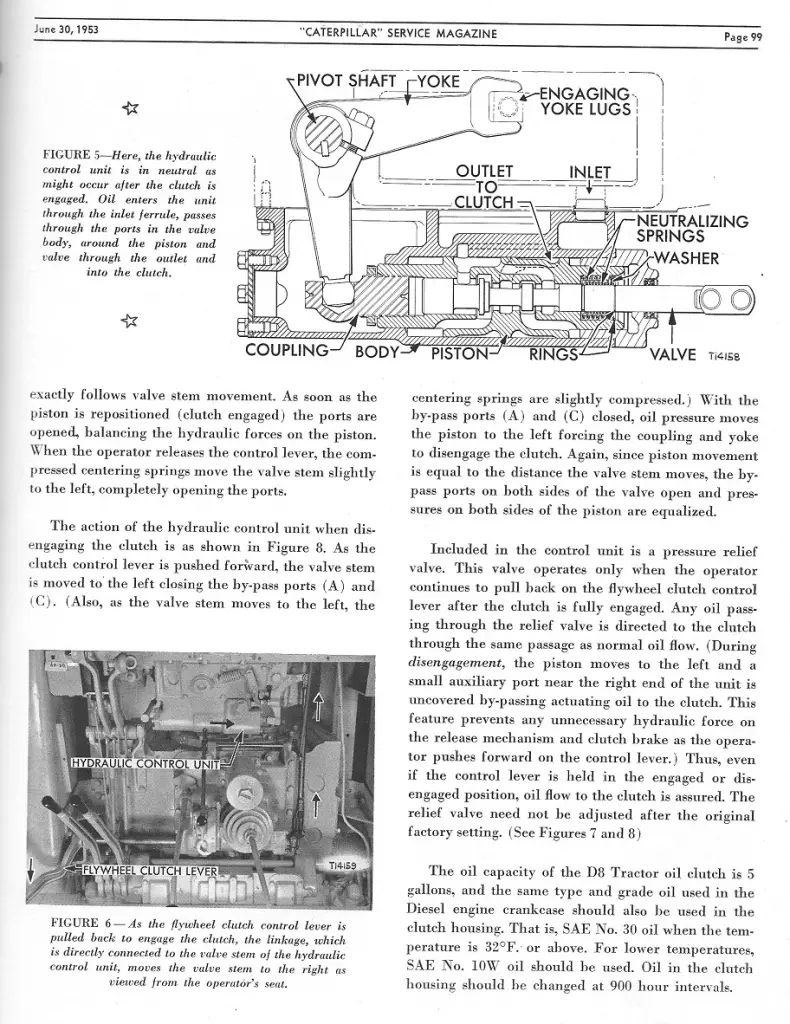

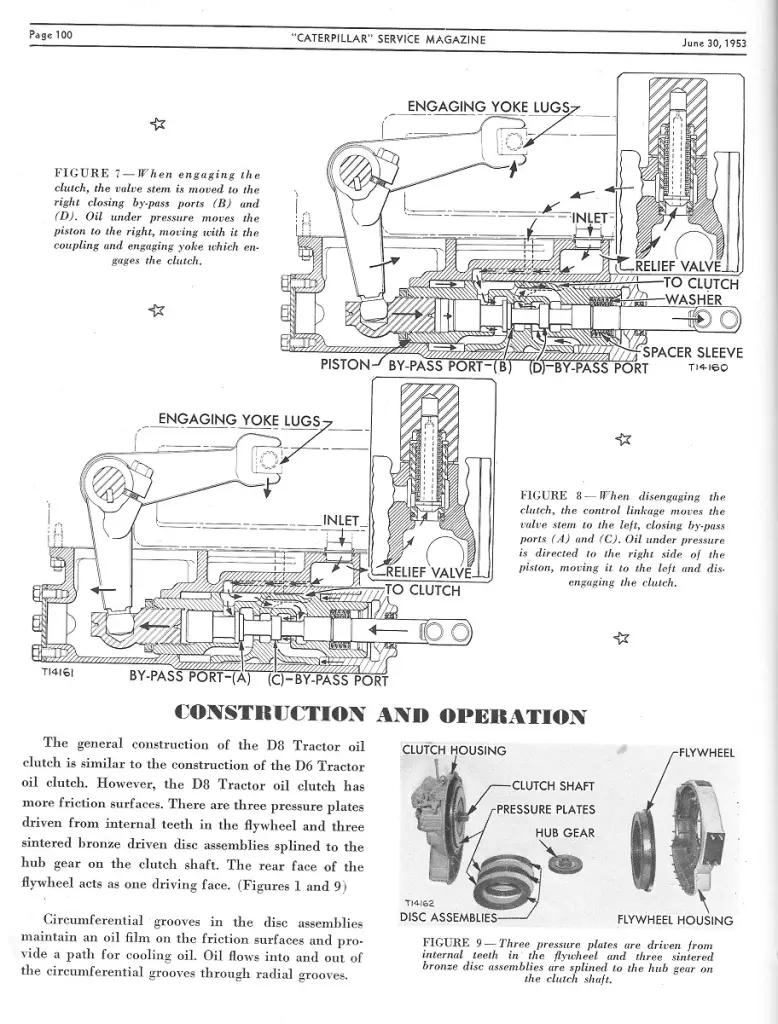

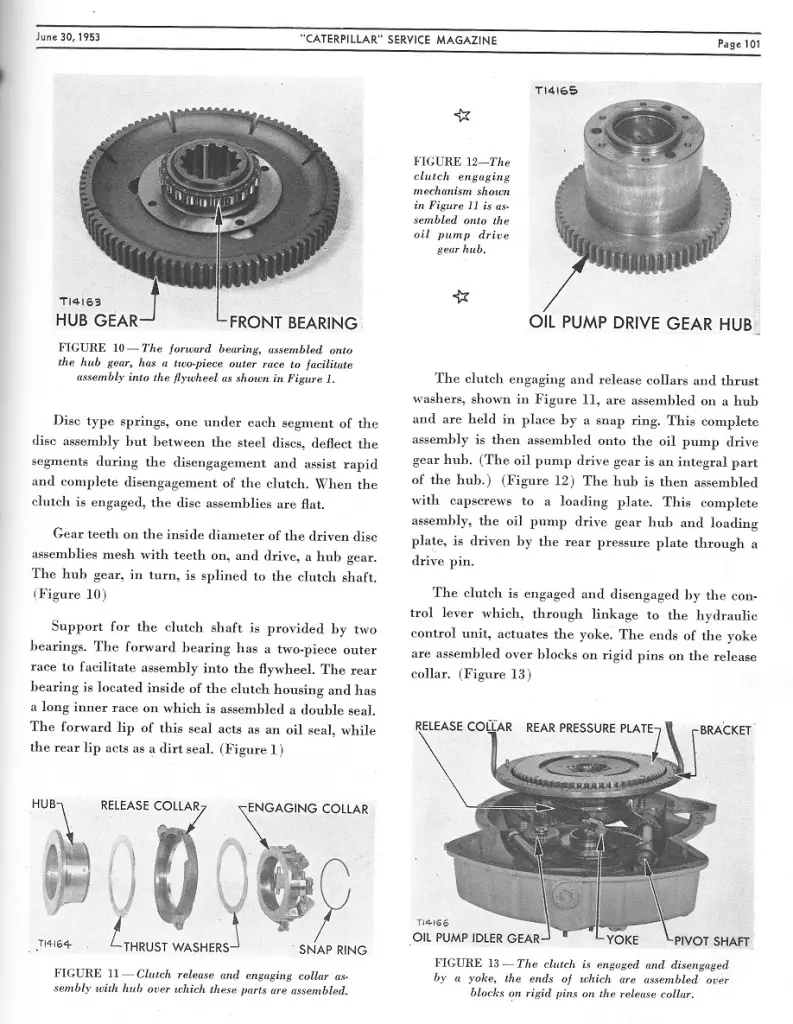

Reading the Service Magazine (June 30, 1953) that my scanner will not copy at present, it seems that when the clutch lever is moved back to engage the clutch the control valve moves and pressure in the system rises until it either reaches the set pressure of the RV or engages the clutch at the pressure required to meet the adjusted clamping force the clutch was last adjusted to (a higher pressure but not necessarily maximum RV pressure) or worn down too (a still lower pressure than the RV setting)

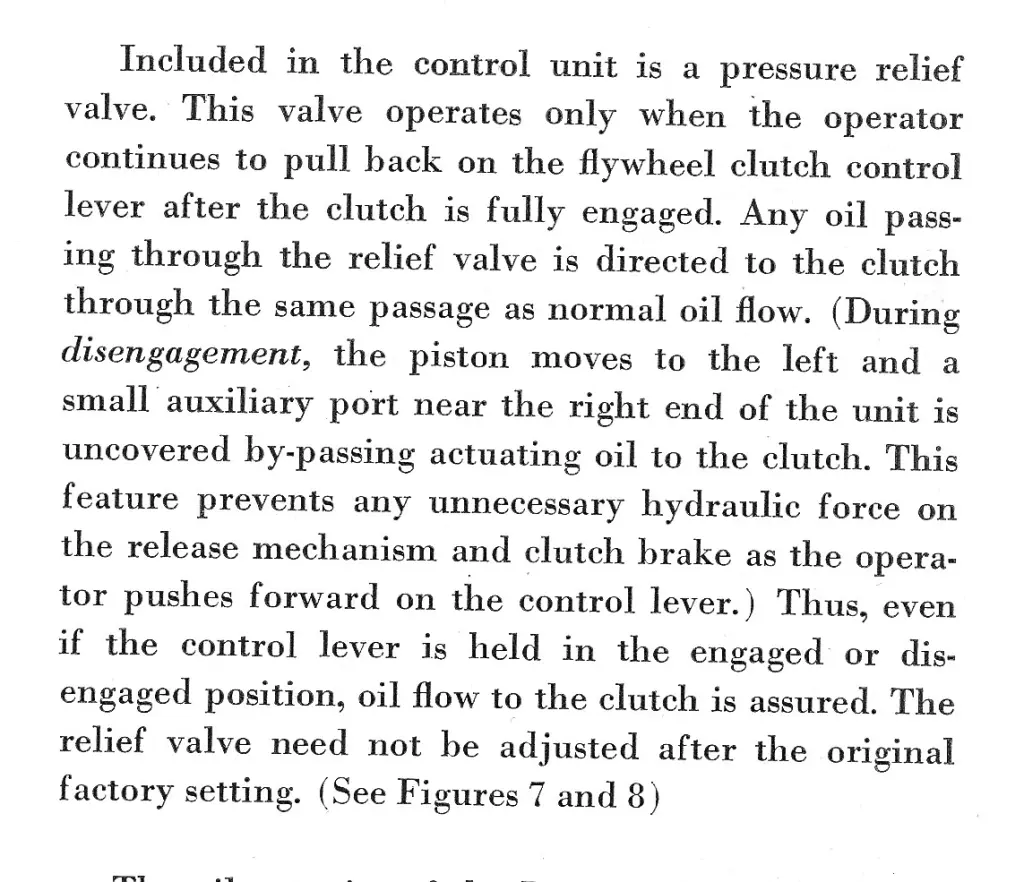

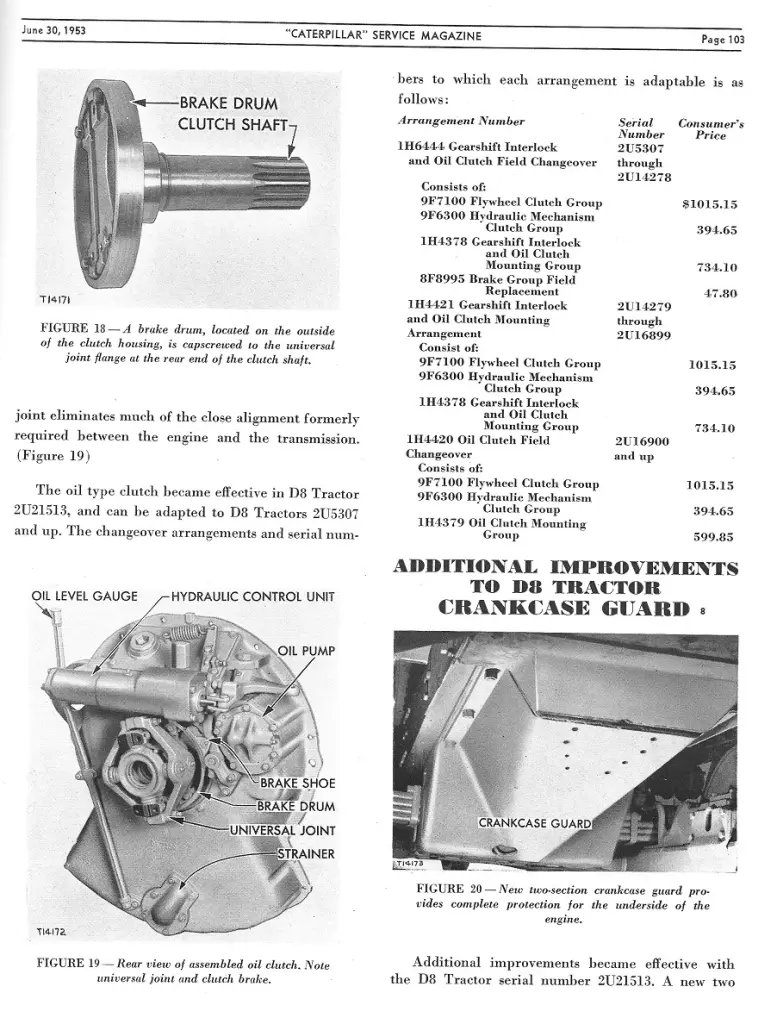

There is provision to still supply some oil to the clutch lube system when engaging or disengaging--when I get to post the scans it will become clearer.

There is little pressure assist in disengaging the clutch to save excessive forces on the clutch release mechanism and clutch brake as the operator pushes forward on the clutch lever.

Hope this helps.

Cheers,

Eddie B.

thanks for your input.

So here is what I have done. I screwed a gauge into the port on the hydraulic control mechanism. When I engage the clutch i pull back on the lever and after the clutch is engaged i dont have pressure at the port. If i pull the clutch lever moving the servo in the pistion of the hydraulic control mechanism (about 1/2 inch) pressure builds to 350 and i can hear the pressure relief valve open. if i release the clutch lever the pressure drops back down. The servo is spring loaded and returns back 1/2 inch opening the port that releases the pressure. I assume that this is normal? Is it?

Does the hydraulic control mechanism only aid in engaging and disengaging the clutch? It doesnt maintain pressure against the clutch discs correct?

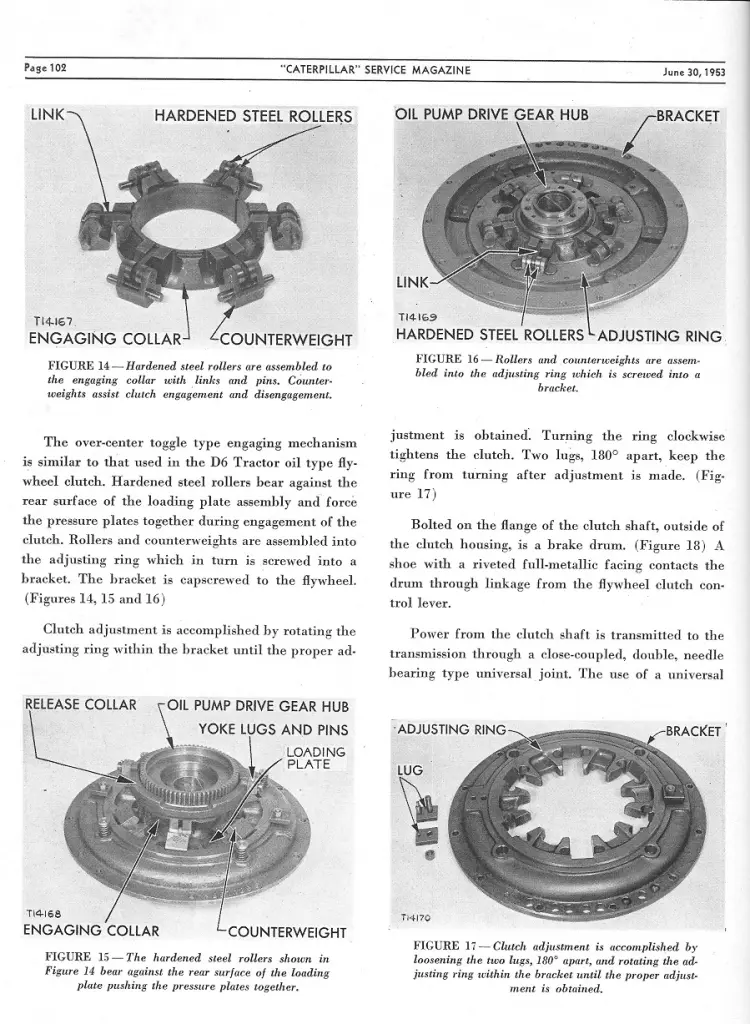

i think that the mechanical linkage is what maintains pressure on the clutch discs not the hydraulic pressure. is this correct?

They hydraulic systems that I have been around dont maintain pressure at the rated pressure until a port is closed which allows pressure to build. But after the task is completed the pressure doesnt maintain and bypass through the pressure relief valve, the valve is released and the oil flows as volume but not under pressure. Im thinking that it would be the same on this hydraulic control mechanism.

thanks

great thanks

can you tell me what the initial setting is on the main clutch. I've read in the operators manual that it is 120 to 130 lbs of pull below the handle on the clutch lever and Ive read in the repair manual that it is 25-35 lbs of pull. can you tell me which is correct?

The 120 - 130 lbs is for the 14A (Direct Drive)

The lower rate is for the 15A (Torque Converter) drive.

Two different types of oil clutch.