I don't see that torch work???? There is some kind of black object hanging outboard of the engine side panels in that one picture you posted. Is that what your referring to?

Can you post the s/n for the tractor.....if you did before I sure can't find it.

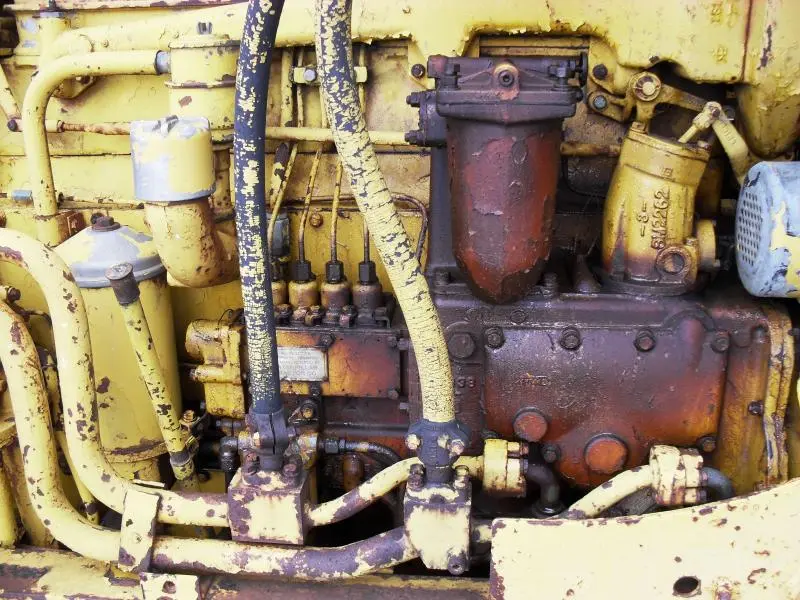

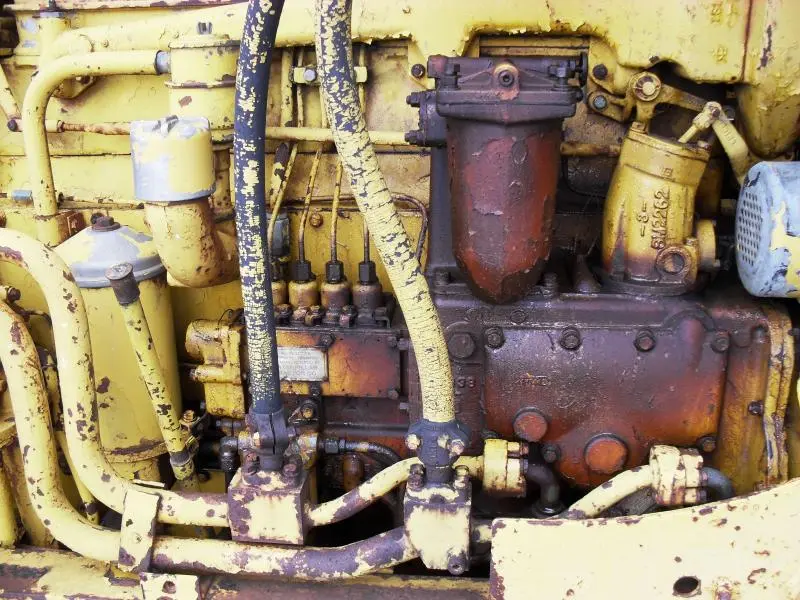

[attachment=12355]D7E IP.jpg[/attachment]I could not find the SN for the machine. I thought it was on a badge by the decomp lever but not there.

Let me post the IP pic.

Yup, does look like torch work......bad.

Check the rear of the steering clutch case, upper LH side. Should be a s/n tag or stamping there.

Hi fastline,

under the small rectangular plate below the injection pumps you will find the pump lifters. These are connected to the pumps plunger by a yoke.

From a post I did around Xmas time, I offer the following :-

"Always resist the temptaion to force the rack to move as you can cause the gear to turn on the plunger and ruin the factory set position.

Spray your favourite loose juice on the plungers and lifters.

The best way I have found to free up the plungers is to gently lever any of the stuck lifters/plungers up and down until each one is free to return by the return spring pressure/force.

You will find when they all can move freely up and down the rack should then move easily.

When you go to start the main have the air cleaner pre screen off and a suitable piece of steel plate or wood to close off the air to the main if it tends to overspeed. Also have a 3/4" open end wrench at hand and after blocking the air flow loosen the injection lines to finally stop the engine--make sure to wear safety specs and keep your skin clear of the injection/fuel spray or you can get severe blood poisoning from any fuel injected into you skin"

The discolouration in your pic I have seen before from a fuel leak on machines that have sat for a long period.

Hopefully it is only that and not an overcooked governor housing.

Hope this helps.

Cheers,

Eddie B.

Not being a specialist in mechanical injection anyway, I was asking Bob about what to expect under that cover. That is all dry under there, is it not? From what I understand, the individual plungers like to stick in the depressed position and not return so if they do not cycle, they cannot pump fuel into the individual injector lines?

So does it take all 4 of them to stick to get a no start or will one hang up the rack so no fuel is provided? Probably make a LOT more sense once I am in but machine is a long ways from me so I have to be mentally be prepared I guess.

yeah, I have that very concern about run away and already had that intake block in mind but wondering if a run away is common on these or not? Is there any way to verify proper operation before firing?

Yes, it should be dry under the cover, as in no accumulated fuel.

The plungers need to be free to pump as well as rotate. One sticking can stop the works. Also fairly common to have the rack stick in its guide bushings.

It's that fuel filter housing that looks like it could have been scorched as the paint is gone and down to bare metal.

I am going to call the owner today to ask about the heating.

I was warned twice now about trying to manually move the rack to free it if stuck but I have to ask then, if it is stuck, how do you free it without concerns of losing timing? Seems there is a timing gear that is sensitive and if moved, we get to start over.

The key is to work gently....start by rolling over the engine to see that the pump lifters function....that's half the battle. Get your fingers in there an feel for backlash of the quadrant gears on the rack. It's these quadrant gears that are to be respected. They are screw friction clamped to the pump plungers (not doweled or keyed) and indexing can be lost if forced.

Once you know these items are ok you can go for the rack which can stand reasonable force if the other items are ok.

Well that's what works for me, others may have recommendations.

Here are a couple of pics......not specific to your model but close enough for what you are doing. Bubble #1 is your rack connection in the governor. Other is typical cross section.

Fastline;

If you should need a set of pumps, I have a set that came from and engine like what you have. They have been tested and are all above the "GOOD" line.

Write to me if you should need 4 [email protected]------Bill Walter