The seat tanks are adjustable for leg room.I can not remember if it is 1,1.5,or 2 inch increments,because you have to change the pipe in the fuel line.The operators book tells you how.Had a friend with one and always talked about moving his seat back as he was over 6 feet tall but never did as there was no easy way to extend the hydraulic pipe and he only used it a few hours a year.So if you are not a tall guy you could maybe move the seat forward.

Ray

It sounds like you may have the later model D2. They were extended a little longer in the clutch area.

Probably the simplest thing for you to do at this point is cut the pipes and extend them.

Another possibility is the setup from a D4 might fit. I just measured a set real quick and it looks like it is approx.

5' 2" from the flange on the selector valve to the inside of the curve in the back. I can drag them out and get a better measurement if need be.

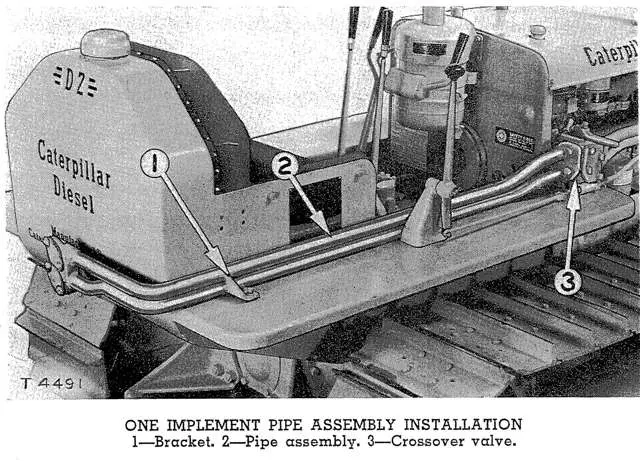

It would be great if the seat were adjustable but my serial number is 4U3630 and the adjustable seats began with serial number 4U6373. My seat is not movable. The later 4U tractors that allowed the clutch to be removed without removing the engine were longer than the earlier models but mine is definitely an earlier 4U. I am thinking of removing the flange that couples the pipes to the crossover valve and welding "extensions" to the pipes where they are most separated and rewelding the flange to the extensions.

I'm a little confused trying to figure out how your rear pipes could be too short, I have always been under the impression the D2's of your vintage had only one length rear pipe assembly, not a shorter one to accomodate the fender tank models. I've scoured my #44 hydraulic parts book and that covers the 6W, 7W, 8W, and 9W series #44 control units, and it lists only one rear hydraulic line group for the D2, containing the 7F4170 rear pipe assy. This pipe fits the seat-tank models perfectly, but every fender tank unit I've seen with it clearly has the pipe a good 6" behind the seat box, indicitave of the fender length difference between the two setups. Are you sure the pipe you have hasn't already been modified shorter? A picture of your current situation may be helpful too. I'm not trying to second guess your conclusions, just interested in finding out if there is actually two different length rear pipes for these D2's. If it would help, I have two D2's with the #44 rear pipes, I could measure them both to compare specs with yours if you would like.

My 44 hydraulic control is a 4W series which is the predecessor to the 6W. I have a parts book for the 4W series and it shows the same 7F4170 pipe assembly that Toby mentioned and a second pipe assembly with a part number of 3H3481. I need 55" from the face of the flange that couples to the crossover valve to the inside edge of the pipe after it turns 90° at the tank. My pipes are about 51". My pipes are bent more than 90° because, and I am guessing, that the previous owner backed into something that pushed the remotes in toward the seat thus bending the pipes at the angle. My current measurement is based upon bending the pipes back to the original 90° angle. I can't give you a photo because I dropped the pipes off a my blacksmith's shop for him to do the extension work and to correct the bends. Thanks Toby for looking.

Ahhhh, that explains a lot. What you have is the obscure optional "rear bumper," not hydraulic lines. 😆 I too looked through whatever books I have on the #44 and didn't see a shorter option. I wonder if you might not have a rear pipe from a #41 hydraulic. My parts book shows 2 different rear pipe options, both without a cross over valve. They are PN 1H7237 and the other is 1H7372.

I show the early 4U up to 6372 as using a 7F4170 pipe assy. and the 6373-up using a 3H6481 pipe assy. (think your 3H3481 is a typo)

I can also find reference for the through pipe assy from pump to rear under group #9F4828 for the two valve system but I can't find any info on it. I suspect it is in the D2 #44 parts book only which I don't have.

How early is that 4W pump? The first 484 units didn't come with float provision although I believe it can be added.

Yeap! I mistyped the part number; the number that I intended to enter was 3H6481. The serial number for my 4W control is 4W294. I suppose that it is possible that the previous owner could have straightened and rebent the pipes thereby shortening the pipes to better fit a tractor with a fender tank. Because the pipes are abnormally bent at the 90 angle, I can't tell for sure what happened... moving the 90 degree bends would be a major project! Unfortunately, there is no part number on the pipe assembly. When I get it back from the blacksmith I will post a photo. This recently purchased D2 tractor has been in a neighboring farmer's barn for many years and hadn't run for the same many years. He was the original owner and because it did not have hydraulics, it did not get much use. It is compete including all the tinwear and in aesthieticly excellent condition... only a couple of very small dents in the back of the fuel tank. I have changed all the fluids and adjusted everything, repaired the pony exhaust manifold pipe and rebuilt the magneto. Based upon my mechanical assessment, it may need a new master clutch and new rear engine seal. The diesel engine is slobbering out of the exhaust pipe and I hope that after putting it to work for day that it will clear up. If not, I will have to put some new rings in it. Otherwise after painting, it will look like new... well almost! My point is that I want the tractor to be as close to original as possible. If the reworked pipes don't measure up in appearance to the rest of the tractor then I will be out looking for a replacement pipe assembly. I am really anxious to put the tractor to work with the hydraulics and see how well it performs.

Yeap! I mistyped the part number; the number that I intended to enter was 3H6481. The serial number for my 4W control is 4W294. I suppose that it is possible that the previous owner could have straightened and rebent the pipes thereby shortening the pipes to better fit a tractor with a fender tank. Because the pipes are abnormally bent at the 90 angle, I can't tell for sure what happened... moving the 90 degree bends would be a major project! Unfortunately, there is no part number on the pipe assembly. When I get it back from the blacksmith I will post a photo. This recently purchased D2 tractor has been in a neighboring farmer's barn for many years and hadn't run for the same many years. He was the original owner and because it did not have hydraulics, it did not get much use. It is compete including all the tinwear and in aesthieticly excellent condition... only a couple of very small dents in the back of the fuel tank. I have changed all the fluids and adjusted everything, repaired the pony exhaust manifold pipe and rebuilt the magneto. Based upon my mechanical assessment, it may need a new master clutch and new rear engine seal. The diesel engine is slobbering out of the exhaust pipe and I hope that after putting it to work for day that it will clear up. If not, I will have to put some new rings in it. Otherwise after painting, it will look like new... well almost! My point is that I want the tractor to be as close to original as possible. If the reworked pipes don't measure up in appearance to the rest of the tractor then I will be out looking for a replacement pipe assembly. I am really anxious to put the tractor to work with the hydraulics and see how well it performs.