Leave the track pads on and run the front up against about a 12 in. block hooked under the grouser. Would really help to have some type of pin holder to support the drive pin, usually bolts to a hole in the grouser. Then it's BFH time....don't hurt yourself.....a little heat will help but don't apply to much to where you loose the temper (steel that is LOL). I'm getting to old to do those anymore, last one was for a D6 and I got a hell of a workout. From now on it's hydraulic pusher for me.

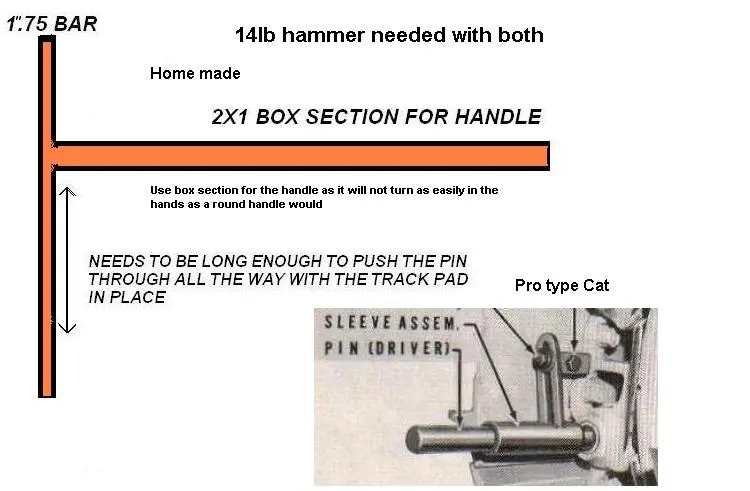

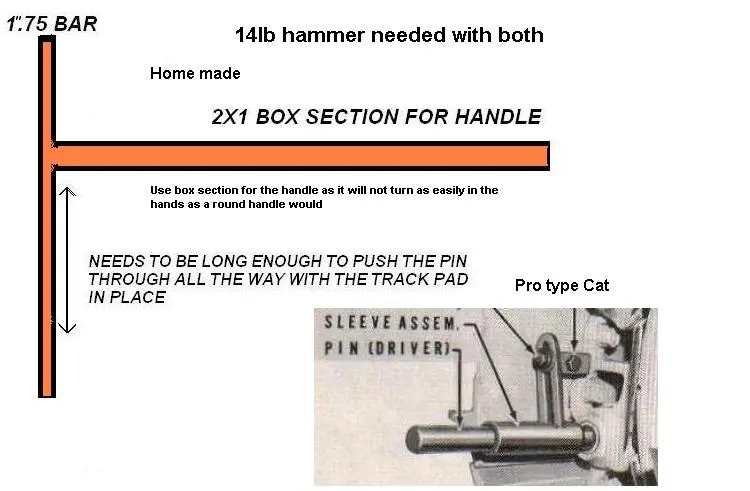

Follow Old Magnets instructions to set the track up for pin removal, you need to make up a pin driver, a piece of bar a bit smaller than the pin with a handle welded to it for a helper to hold or make one like Old Magnet suggested that bolts to the pad,when the driver is made first try to knock the pin out cold and if it does not move after half a dozen blows of at least a 14lb hammer or so heat the link boss rather than the pin,do both sides,the pitcure below will give you an idea of the the drivers,no hammer required with the hydraulic one,you and the helper use eye protection.

AJ

Thanks Gents,

Ended up getting a drift from a neighbour, set it up on top of the C frame on top of a piece of 2x6, got myself a step up level with the C frame swung the 16lb Tool-fine adjustment like a golf club and it came out fairly easy.

l had a feeling the press method was probably causing binding.

Did a quick 320km round trip to the nearest town of consequence and got the seal, $10. Will get that sucker buttoned back up tomorrow, just in time for the freeze and some clearing work with the old beast.

Cheers.