Hi Cat951,

as the 951 has the fuel tank level above the level of the fuel system I doubt you are experiencing fuel drain back, as, there is always a positive head of fuel keeping the system full of fuel.

Your governor may have a rack limiter that needs engine oil pressure to be built up before the rack can be moved further than about a fast low idle position.

If you try and move to full throttle before oil pressure is built up, the governor lever can trap the limiter valve/pin and you still only have low idle+ fuel.

When oil pressure shows on the gauge then open the governor lever and you should get full fuel for an easy start.

At The Dealer we always used to pre lube the rebuilt engines with an oil pressure pot we pressurised with shop air. This filled the lube system so we did not have to crank the engine to get the system primed--wears out starter motors realy quickly by the time the filters etc. filled with oil and, the pressure could then build up and retract the limiter for a good fast startup.

What this means is that the longer your engine sits the more oil that drains back to the sump from the filters etc. and then needs to be pumped back into the lube system to get oil pressure up to retract the limiter.

The injection pump needs special tools and skills to remove and refit the plungers and barrels(injection pumps) and hold the rack in the correct place to do this.

The injectors can be tested and de-carbonised as needed. We had an ultra-sonic cleaner at The Dealer to decarbonise the injector tips and orifice.

Hope this makes sense for you.

Cheers,

Eddie B.

Hi edb,

one can not remove or block this rack limiter in full fuel position?

Compact fuel system is the same as scroll fuel system?

Thanks

Hi Cat951,

just re-read your post and, I guess that spacers could be made to keep the limiter piston in the retract position.

The rack limiter can not be blocked out easily, but, one may be able to remove it as well as blocking the oil supply drilling leading to the limiter piston situated in the governor housing.

There should be a plug with flats that are about a 3.5mm across, that is the supply drilling plug. It would need a closely/tight fitting piece of round rod to slow down the oil flow which will go to drain if the drilling is not blocked. This would flood the governor housing and cause the governor some problems in time due to the weights etc. spinning in the flood of oil there. The gov. would also be sluggish/slow in operation.

There is a cap with flats of about 25mm across behind the governor housing that has the limiter piston and spring under it. It is in close to the cylinder block but I think you can get it out without removing/loosening the gov. housing on the injection pump. It has been such a long time since I have removed an injection pump to remember.

Hope this helps.

Cheers,

Eddie B.

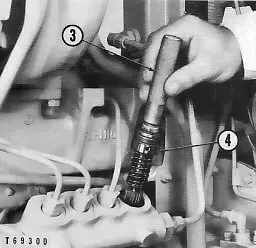

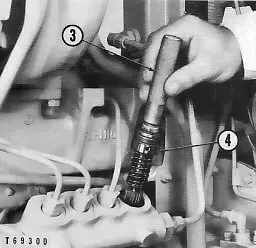

PS an example of a Cat Compact pump scanned below. The compact pump is a scroll type injection system.

I think I understand and I thank you for the explanation.

Another question:

There is additive or something to be added to diesel to clean the system?

When I removed the diesel pump, tranfers I found a lot of dirt inside of it and within two holes of inlet and outlet diese in the seat of the pump.

Can I remove the filter turret to clean all the diesel passages?

Thanks

Hi Cat951,

there should be a fuel strainer bowl under the Injection Pump Drive just behind the Fuel Transfer Pump. It should have a wire mesh screen in there to stop the bigger sand getting into the transfer pump.

Also no problem removing the fuel filter housing and connector tube to clean out the passages etc. I suggest you fit new seals and gaskets as needed.

Diesel Fuel additive can help clean up the injectors so they atomise the fuel as designed.

Cheers,

Eddie B.

A 951C should have a glass water seperator under the fuel tank,also I think it should have the sleeve metering pump,it was common for the rack in that pump to stick in the stop position,when you shut down the engine with either pump move the throttle back to the high idle position and leave it there,see if doing that helps it start easier,about cleaning the fuel system,any dirt in the system comes from the tank,clean the tank first and then blow out the lines after disconnecting them,your glow plugs are working?.

Good luck

AJ

Hello Aj.,

Unfortunately my 951 has no glass water separator, but as he says edb, a metal filter under the pump, which, however, lets a bit of dirt, saw what was in the transfer pump.

The injection system is "scroll fuel system". You say that it should fit "sleeve fuel system"? The Caterpillar dealer who sold it to my father said it was a C series. The serial number is 69h2969, the engine 48v4343, the year 1973. The dealer told me that the C series will start from serial number 69h1819.

However, I think to mount a pre-filter water separator under the tank as soon as possible.

The plugs work well, the current draw is 5-6 amps each one.

The problem is that for a while, does not seem to get fuel, such as the barrel that go from the pump to the injectors is empty a bit.

One question: the injectors also have the function of non return valve?

Thanks

Hi Team,

AJ

I also thought it should be Sleeve Metering, but, the Transfer Pump that Cat951 enquired about in another thread to do with his machine was clearly a Compact System Transf. Pump. Also above he asked about the Compact system so that is why I posted a pic. of a compact inj. pump to be sure.

If he had a Sleeve Metering Inj. Pump then air trapped in the rear governor housing causes the exact problem he has described. Bleeding the air out of the Rack Stop Housing just to the rear of the big side cover plate cures the problem.

I like your idea of leaving the throttle at mid position, after shut off, so as to get full rack for the next start.

69H is a French sourced machine and I was told by British and Scottish fitters at our Dealer that some European sourced machines around this time could have Bosch Injection Pumps fitted !!!!! I do not have acess to Literature for these later machines so my help is limited to the descriptions or pictures of the systems by the owners.

Cheers,

Eddie B.

According to the book I have the sleeve metering system came in at 69H 3509.