yes you can have it off as it's running, there is nothing right there slinging oil, just plungers going away at it, and the rack of course.

Since you mention a load, I guess it's making kW👍

How fast is the motor/generator turning? I expect you have a pretty steep power vs rpm curve as you attempt to increase the speed, so I wouldn't exect to get a whole lot more rpm out of it before the hp doubles. Only exception would be a design D motor where the torque/rpm curve is more gradual instead of almost a straight up line.

figure 7-26 in this PDF file shows the typical curves

http://www.mhhe.com/engcs/electrical/chapman/fundamentals/ind_motor.pdf

What is the motor current? What is full rated load amps?

Should be able to nudge the rack to touch the torque spring and see if it does indeed have any more to give or fuel is somehow liminting or something.

Hi Jack,

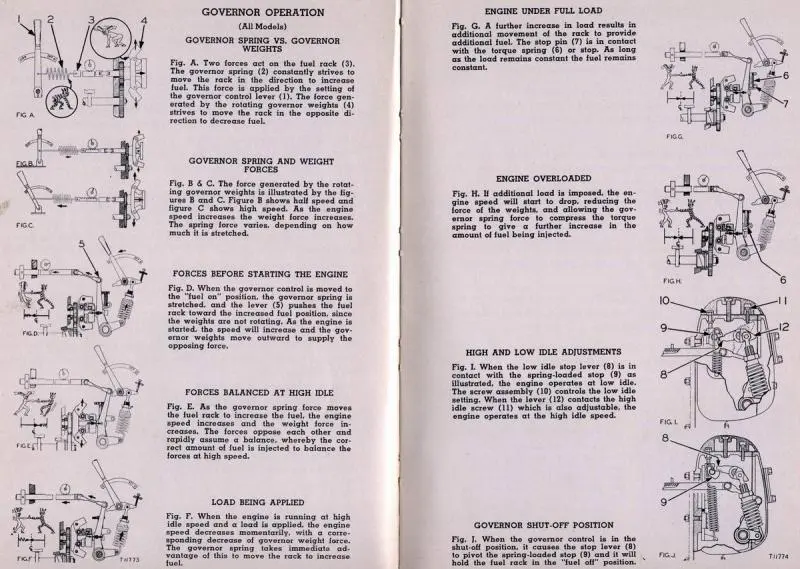

There are several governor arrangements, might check out what you have. There is a whole additional page on the 7S Industrial series.....can't remember what you have, I'm thinking it was out of a D2 tractor.

Thanks all for the input.

First off, I'm going to take the cover off and see just what the rack is doing.

As for the pictures, they are the same ones I copied from a 5U service book. I thought there'd be some help in there, but it is too general in nature. thanks all the same.

The motor/generator plate @ 230 Volts states 68 Amp, Service Factor 1.25, SF Amps 86, rated 25 HP. I managed to get 40 Amp out of it. The hand-held tach indicated about 1250 engine RPM. Since it made 35-40 amp @ 1250 RPM+/-, I'd assume that the operating speed is going to be just a little bit over 1250 to get my full 68. I was shooting for about 1400 RPM, but Cat spec sheet indicated that the engine was good for that at 1200.

Correct, O.M. The engine is a 5U tractor engine made of pieces. The block is a very early one that had everything full of rust. The governor and most other parts came off of a later one that was frozen and broken in places I'd never seen broken before, but it wasn't full of water. The crank/bearing set came from Idaho. "It's a bits o' engine," as my motorcycle restorer friend would say.

We have this engine

Waiting patiently

He has just 15 hours

itzik

I think you're on the right track. Look in there and give the rack a nudge toward the left/front of the engine while it's under load.

Might have to go up on the high idle speed to get the necessary power out of it because of the droop of your governor, if you have the safeties to handle it if it trips off-line. The gen set governors shown on the rack setting chart calculate at 1.5-3.0% droop where the tractor governors are 8-12%. The 8% is on the higher idle speed setting with the same governor group and spring, so just setting up the high idle would probably decrease the droop some. I'm guessing it's just because of the higher rpm the governor is operating at.

I would say the main problem is likely the main governor spring. I know SJ said many times he replaced the governor spring and perked up a "lazy" engine. The symptoms don't really sound like flat spots, bad bearings etc in the governor because you're at a steady load, but I guess it could get back to that.

Barring any problems like that, getting full power out of it depends on the pull of the main spring vs the power of the flyweights. Weak spring cannot overcome the flyweights spinning at full rpm, so it runs slower. I'm guessing a weak spring mainly causes increased droop.

An OEM CAT genset governor would be just the ticket, or go electronic. Might be easier than finding the correct OEM part for your old engine.

I didn't do the rack check under power today, didn't have a helper to hold down the start button to keep it connected. I noticed that the governor spring is screwed onto a hub, and that hub is on a threaded rod and secured with jam nuts and a keyway tab washer. (I found a rusty one in the bone yard.) Is the length of the assembly ever adjusted? I have found no spec for the length of this assembly nor any reference to adjusting the length in any service book I've seen so far. The spring has it's own part number in the parts book, but it is included in a governor spring group. Was this spring ever sold separate from the part group? Is this a factory calibrated group that's to not be messed with? Will I forgo any chance of paradise if I mess with it?

Thanks, ccjersey. I'll let you guys know when I find out what's going on. My wife has committed to holding down the contactor tomorrow. We'll see what happens.

Jack