Jack,

That is a real professional job. Glad to see that she is up and running. A few years ago we were at the same point in the rebuild on our D2 engines. I'm real satisfied with how mine runs as well, a few things that I want to take care of still, but know that it will never be "done".

I'm glad I pushed hard to get mine done when I did. I gave me a couple of summers with it back together and with my Dad (it was his D2) before he passed. It was worth every $$ and hour spent getting her going to see him run that tractor again.

Tim

Hi Timbo1946,

Yes, I remember exchanging experiences on the rebuild of our engines. I had mine finished about the same time that you did, but I had to oil it up and leave it on blocks for a couple years or more. Seems I'd work on this project until I ran out of money, then wait and scrounge parts until I could go again. After the engine work, this has taken me just about one year of spare time to make what you see in the picture.

It cost me close to $6,000 to get the delta closed on the power line out front last year. Then I had to stall the electrician until I could afford to pay him and putter about on the small detail jobs. boy, was there a bunch of small details, what with water heat coils on just about everything. So I'm way behind schedule with it but saved a bunch of money by not farming out anything except the electrical.

Now spring is sprung and sparkie is real busy, so it will be a couple more weeks before we can wrap this thing up and go on the grid. With all the time loss, I've managed to pile up about 1,600 gal of fuel and it keeps coming on a regular basis. We're fueled until some time in 2013!

I'm happy to hear that your project worked out well. My Dad was a gardener. After he blew a couple air cooled engines, I built him a garden tractor around a 4 cylinder Waukesha engine. He treasured that thing until the day he died. It's still here and still running after 41 years of tilling.

Regards,

Jack

Hi Team,

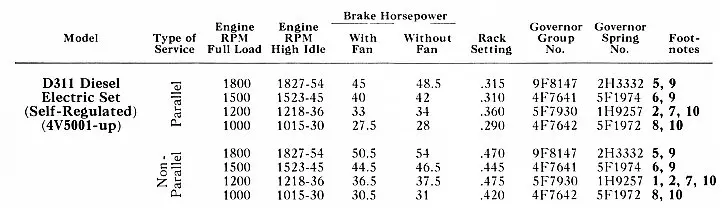

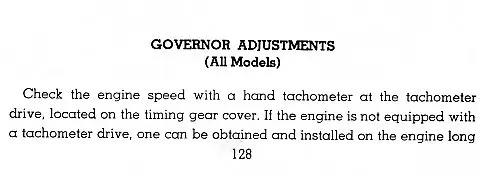

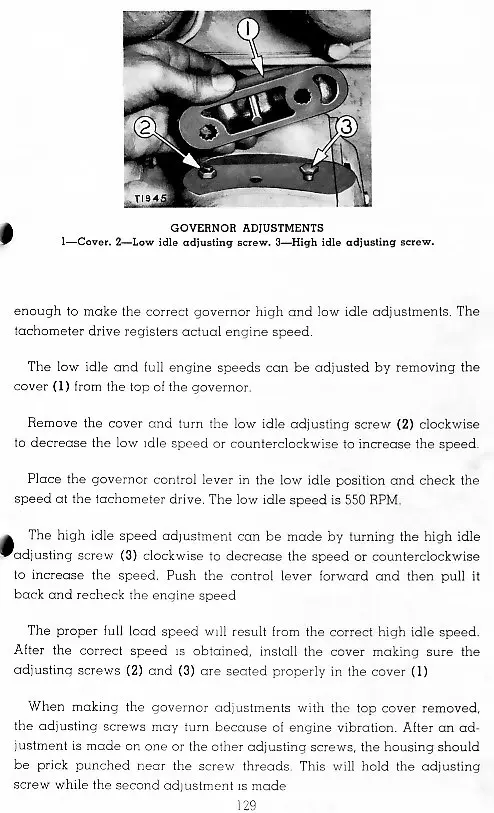

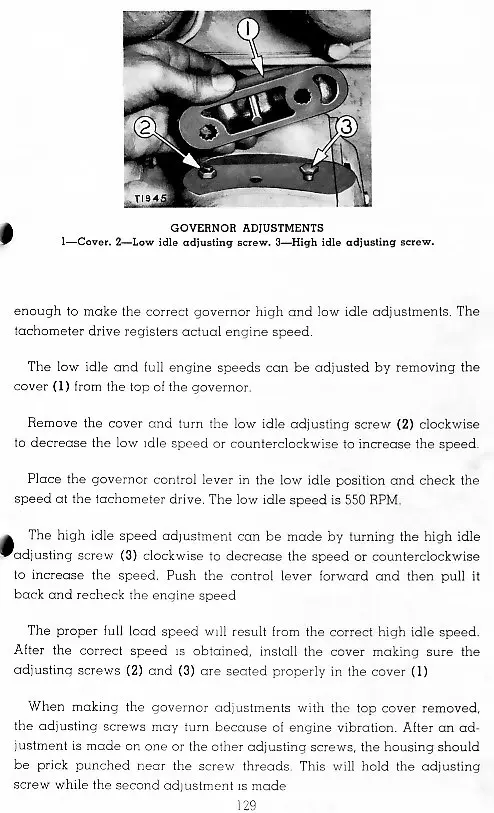

scanned below is the procedure to adjust the High and Low Idle speeds for a tractor.

A "Cat" Gen Set usually has its Low Idle set at about 500 RPM less than High Idle so as to save the regulation system overloading trying to maintain settings with the engine running at less than its rated speed.

A Cat gen set governor is usually set up with 3% droop.

Thus a "Non-Parralled set" with 1800 Full Load rpm has a High Idle of 1827 to 1854 rpm, and a Low Idle of 1300 rpm, = 50.5 hp with fan.

1500 FL has HI 1523-1545, and LI 1100, = 44.5 Wf.

1200 FL has HI 1218-1236, and LI 900, = 36.5 Wf.

1000 FL has HI 1015-1030, and LI 800, = 30.5 Wf.

Hope this helps.

Cheers,

Eddie B.

Your governor should have an easy time with the induction generator.

Should be able to just dial up the high idle speed until you get the amperage output you want as long as it won't overspeed if it trips off line/belts slip etc. That might be the only fly in the ointment using a tractor governor instead of a generator governor.

About the cheapest thing that's useful is one of those ebay photo/laser tachometers. I have had 2 now. The first one (~$25) died after several years of riding around on the dashboard of my truck. I got another for about the same money and I'll try to take better care of it. They're easy to use, accurate, safe and cheap if you can find one of the same ones I have (shipped direct from Tiawan I think)

The contact type can be used for a lot of things, but it can be a challenge to safely stick it on the end of a shaft in a lot of situations. They generally are more expensive than the cheap photo tachs unless you pick up a really good deal on one.

That was a typo that I didn't catch on the generator speed. It's actually around 1785 RPM, but you get the drift. The diesel won't be running near that fast. If the motor should lose connection, it would overspeed immediately. I'll have the control system set up to leave the switch off until the fault is corrected. Then the gen can be switched back on manually. For this reason, I have to set the high idle at an acceptable limit no-load high idle speed.

Neil,

I have a couple of tach you could use. Both are contact type, so you have to be able to get to a rotating shaft. I have used the PTO on my other tractors to measure and ajust, just have to know what speed the PTO is set up for. You are more than welcome to use. Just let me know. I'm in Williamson NY, not to far from you.

Tim