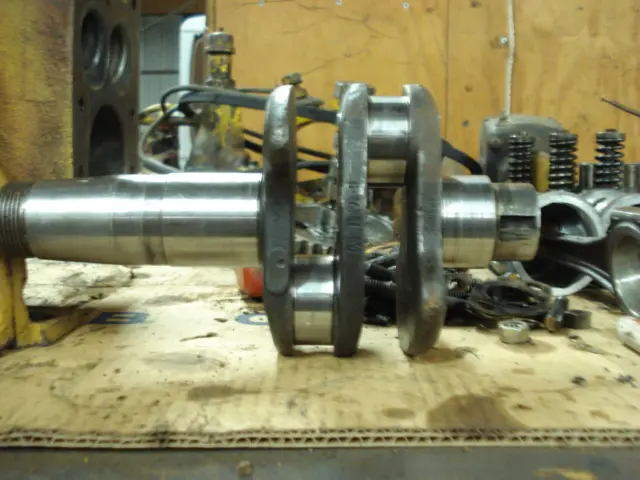

Main 1.8120-1.8125in.

Rod 1.7495-1.7500in.

Max out of round is 0.003in

Bearing clearence with babbitt bearings is 0.002-0.0055in

End clearence is 0.010-0.015"

Max permissable bearing clearence is 0.015in

And Max end clearence is 0.025 in

I was wondering, these measurements? are they the factory standard or is that what they are for undersized, I measured one of my mains and got 1.082

Thanks,

Pat Bayer

Those are the standard dimensions for all the small pony motors that fit the D2, D4, D3400, D311, D4400, D315 etc.

Recheck your measurement since that would be 0.730 inches undersize! If it checks out, someone went a little overboard on the crank grinding! Maybe 1.802" (~0.010" undersize)

What about the rod journals?

Sorry, I made a mistake,

I measured the most worn postion I could get to get the smallet diminsion

The main on the flywheel side measures 1.8041, the back bearing measures 1.7848

The rod journals are both 1.7352

I notice that in the parts manual, a main bearing that is .030 under is not offered, I wonder if its offered, or should I be looking for a crank shaft?

Thanks, Pat Bayer

You can get the crank welded and reground to standard. You might need to check around for a shop that can/will grind a hollow journal.

When I got my D2 the pony had a spun rod bearing and I found this place Waterhouse Motorsthat would weldup and regrind the hollow journal, they also reground the diesel motor crank as well.

Kevin

Kevin

I believe some folks have made non-standard bearings to suit their crankshaft after it has been turned. It should be possible since these are not halves, but I'm not a machinist. Look at this thread

http://www.acmocbb.org/ACMOC_BB/showthread.php?t=3386&highlight=pony+bearings

Any way to pour babbit in these?

I have the head off of the main engine, I am questioning about pulling the injectors, I pulled the one, and one of the pictures should show how it came apart, wondering if that would be normal, Does that have anything to do with adjustment?

I think that the valve guides are the primary source for the slobbering, the oil was probably running down the exhaust valves and being blown out the exhaust, the oil that was going down the intake was being burn, I have not yet decided if I want to pull the pistons and see the rings, I probably should,

take a look at how the one picture shows how pluged the on exhaust port is in the head

Thanks,

Pat Bayer

R4pat

ccjersey refered you to my post about repairing the main bearing surfaces of the crank. I turned the undersized bearing surfaces down and made sleeves that press fit with locktite bearing mount for the crankshaft. Then I returned the mains to standard size and used standard bearings. Pony has been running for about a year with no problems. Even in the cold weather we have been having here in Missouri the pony will start (rope start) on the second or third pull.

Brian Boaz

Does anyone know the standard bore for the pony and also the main diesel engine

thanks,

Pat Bayer