The rear seal can be replaced without removing the torque divider. Unbolt the two retaining bolts to remove the drive flange once the universal joint is removed.

You need to run some pressure checks on the torque converter/pump system to help diagnose what is going on. Also check oil filter element, magnetic strainer and scavenge pump inlet screen for metal particles.

Thanks for the info old magnet, I had looked up at it last spring but when I had the stump pans off but couldn't really see up in there at all. Is the drive flange just a loose fit?

I cleaned the magnetic strainer and put new filters in it as well as changed all the oils but didn't know about the suction screen in the torque till I had it all back together.

I just bought this crawler last spring so I'm still learing as I go. My dad owned one years ago but never had to do any work on it so he doesn't know much about them either. He only owned it for a couple of years and then sold it again. I'm hoping to eventually get this one fully restored with new undercariage and all.

Where abouts can you hook into to check the pressures??

Thanks Ryan

I think you should check out the pump suction line for leaks first. If it's sucking air it will act that way and the pump will be buzzing or ratteling like it's full of marbles. If that checks out good we can talk about pressure testing.

Later Bob

The drive flange is a slip fit on the output shaft splines.

What is the serial number of your tractor?

What did you find in the magnetic strainer??

Depending on your model check the hose coupling clamps or hose clamps on main suction line.....also mag strainer sealing...as Bob mentioned.

There are several pressure check points....some use 1/8 in. - 27 NPT plug ports and some require the 7M1293 adapters. I have all the info and specs....Bob can point us in the right direction.

The serial number is 48A 5134. It's a 1964 but has been upgraded with a high horse engine.

There were some very fine cuttings but nothing unusual. At least I didn't think so. Transmission filters were a little bit dirty and you could see some fine cuttings in it as well but there again nothing really jumped out at me. When I pull the strainer on the torque do I need to drain it first? I'd assume so but don't want to if I don't need to.

I found some info in one of my service manuals as to where to hook up the gauge as well as what pressures should be there. I bought a set of millitary manuals for it and had to do a bit of looking but did find it. Just depends on what I actually need to test for I guess. Transmission pump pressure says to check off the top of the pump and it should be 310-330 psi. Engine at high idle and selector leaver in neutral.

This spring I had the steel line off the magnetic strainer spring a leak so I took that all off and replaced both lines with rubber hoses. Saved the cat ends and silver soldered them onto a machined fitting. I didn't want to have to go in there again after braizing them up to have to fix another little crack. I didn't have o rings to replace the old ones when I was at it though. I didn't have any lines off at the pump itself though. There looked to be some small oil leaks coming from some of the flange fittings on the scavenger pump.

I did check the hose clamps on the main suction line when I had the belly pans off and the clamps seemed to be tight but if the hose was hard it maybe wouldn't seal up anyways. I didn't really check the hose it self to see if it was hard or not. It did have the good hose clamps on it not the cheap radiator ones.

There's a slight wine to it when you start it up and when moving. Not when you very first start it up but a couple of seconds afterwards as the oil starts to flow. No strange sounds from the pump when it wont shift into gear at all.

The first time it hapend I thought maybe it was in the shifter linkage as things are pretty sloppy in there but then it did it more repeatadly when I got it warmed up good the second time. Seemed to do it more when I'd put it under a bit of a load when I stoped. Like if I put the blade down then pushed and stoped and put the brakes on.

Thanks for the info guys, I'm sorry to be long winded here but trying to explain and describe the best that I can.

Ryan

Yes, you will need to drain the torque divider housing to check the scavenge pump inlet screen.

Main oil pump pressure and instructions are good and one of the main things to check. This is one of the 1/8 in x 27 NPT taps.

Doesn't sound like a serious suction leak but I'd be suspect of reusing old "O" rings.

There are two more pressure checks for the torque.....outlet relief valve @ 42 +/- 5 psi and torque inlet relief valve @ 115 +/- 6 psi.....these will require fitting adapters.

If everything checks then it's on to transmission tests.

Hi Bob!....a yay or nay if we're on the right track😊

One thing I always found on the high horse 7E's was that the trans worked better and lasted a little longer if the pump pressure was set at 350 to 360 PSI. They would lock up a lot better at that pressure.

I think some new Orings on the suction line flanges might stop the whine from the pump. The shift lever resisting going into gear is a low pressure problem. On the older powershift transmissions they had a spring and rod that forced the valve into neutral when there was no oil pressure. This was to make sure you didn't start up in gear. Newer trans had a reset feature and had to be shifted into neutral before they would build clutch pressure if they where started up in gear.

Any gets worse when warmed up problem is a leak so get a line and gauge into the trans filter top and check pump pressure. Should have a 3/4" hex plug with 9/16"NF threads and oring(STOR BOSS).

Let it warm up and check pressure at low idle and at high idle in neutral and then shift it through all the gears at low idle.

Record pressures and come on back.

Later Bob

When I shift it into gear the whine stops then once I start moving you can hear it again.

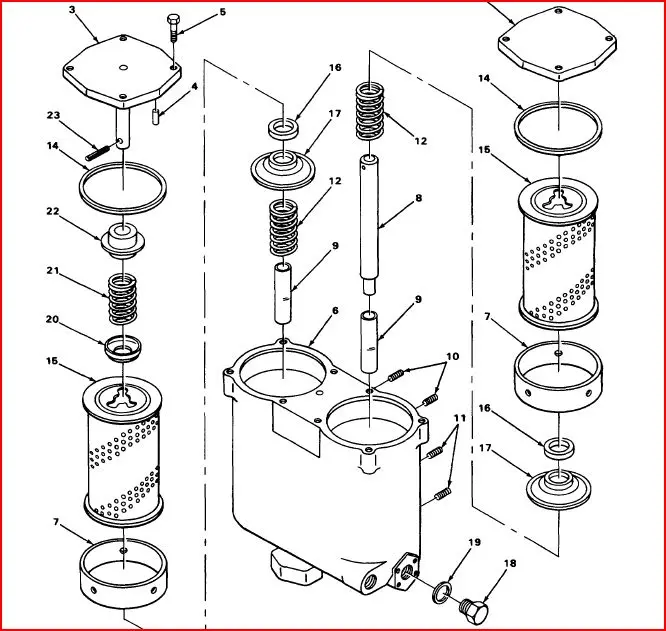

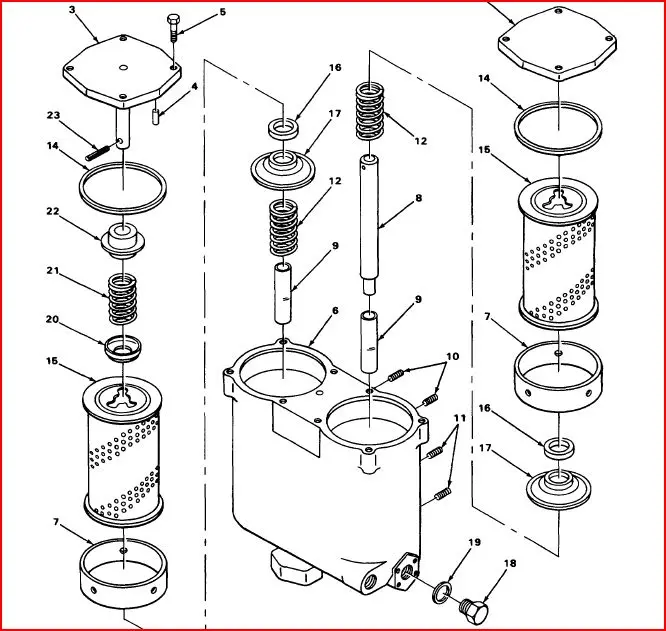

I don't recall seeing a plug on the filters at all to check the pressure on. Here's the parts diagram for the filters and housing.

[attachment=2277]Capture2.JPG[/attachment]

It's probably going to be a couple of days before I can get ahold of a gauge. We haven't got any lower pressure gauges kicking around here at the farm at all. Got a 5,000 psi but would like to get a 500 psi so I can get a more accurate reading.

I'm trying to get the crawler fixed up for winter as I need it for snow plowing when we are logging. So I've still got a bit of time to get it ready. Snow is coming quicker then we would like it to though I'm afraid.

Ryan