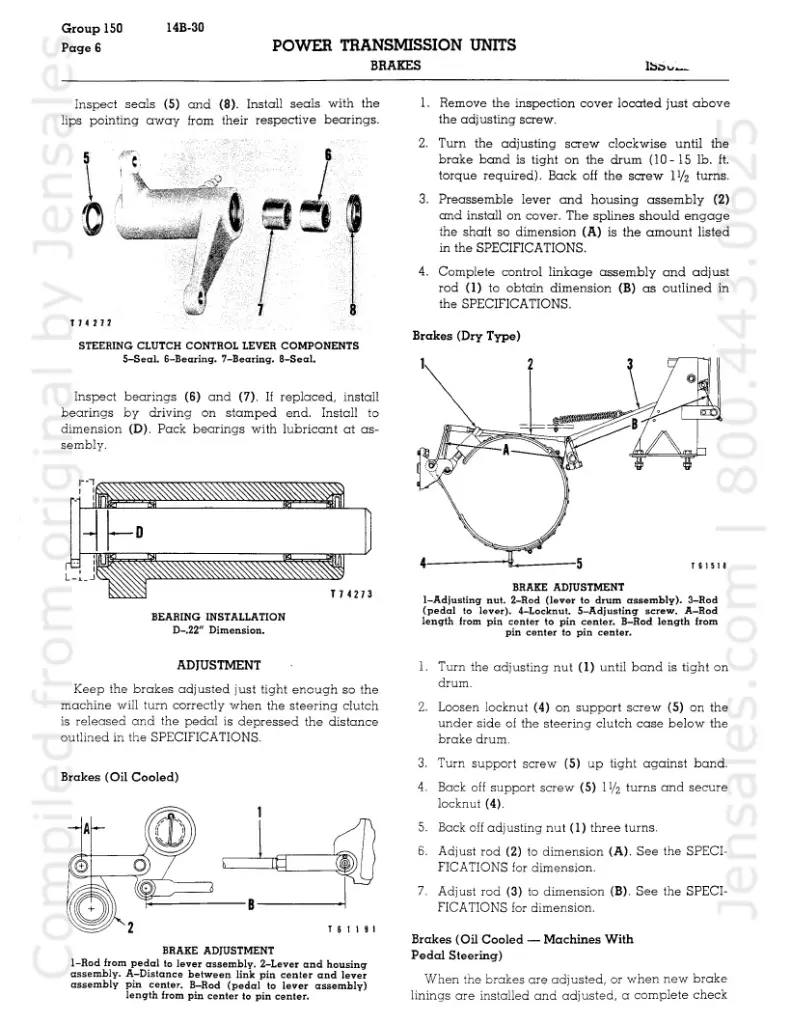

Brake band adjustment procedure is to tighten band all the way with reasonable torque, then back off 1-1/2 turns. If that's not the response you get adjusting the linkage isn't going to gain anything.

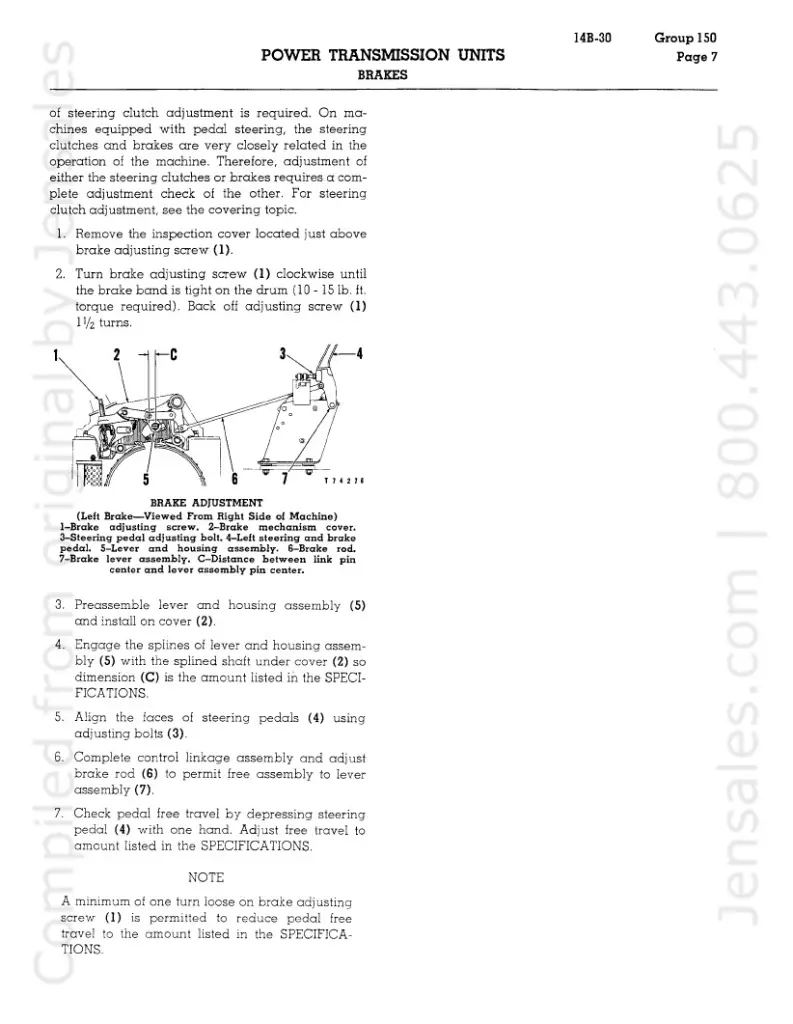

Thank you for the reply Old Magnet. Can you please help me understand why the linkage adjustment is mentioned in the service manual in conjunction with the brake adjustment? The previous owner mentioned that he "adjusted the brakes per the manual" and it is making me wonder if he adjusted any of the linkage incorrectly. I'm wondering if it is worth checking or if I am more likely just to mess something up by tinkering with it. I also can't understand why each band would have about 1/4" of lining left but not be able to be adjusted further to get more braking. That just doesn't make sense to me. Any clarifying information would be greatly appreciated. Service manual pages included for reference.

[attachment=74827]977H brake adjustment 1.jpg[/attachment]

[attachment=74828]977H brake adjustment 2.jpg[/attachment]

The picture makes it look like U series D6 brake if this is pre pedal steering in the 977. In the D6 you are just seeing the end of the brake lining that is the least worn part of the lining. So my guess is you are ready for new lining on the rest of the band. If it is not pedal steering I don't see you causing yourself a head ack if you play with linkage. From fiascos in adjusting D6 steering boaster linkage I would caution you if the this has pedal steering.

Thank you. It does have pedal steering. From my understanding the 977 wet brakes are very similar, if not identical, to D6 wet brakes. If the local mechanic wants a crazy amount of $ to do a brake job, I am thinking that I'll just attempt the job myself. Does anyone have any opinions on what a brake relining job ballpark cost should be on one of these? I have a mini excavator that I can use to lift off the fuel tank and lift out the steering clutch and brake band. If that won't do, I'll just pull it under a big tree and use a chain hoist. I don't want to get into anything that would involve removing tracks or messing with finals, but is there anything else that is relatively easy to do while the clutch and brake band is out? Seals? bearings? Trying to wrap my head around this job.

Picture below with the floor plate removed:

Yes, you will need to pull the steering clutch assembly to remove the brake band for relining. That would also be the time to check steering clutch/disc thickness according to spec. Also check the condition of the splines and clutch disc teeth.

The brake adjustment process starts with tightening the band and then backing off the suggested amount. Once you have that then you proceed to adjusting the pedal linkage.

If the brake band linings happen to still be close to original thickness (about 1/4" all around) but you still can't adjust them up then it is the drums themselves that are worn and needing replacement.

Thank you Old Magnet. I hadn't even thought that the drums could be worn. I just assumed it would be the lining.

Just a reminder when working the beast. The bevel gear hub is the weak link in the drive line. That's still just a D6 8/9U hub arrangement.

[quote="Old Magnet post=253774 userid=632"]Just a reminder when working the beast. The bevel gear hub is the weak link in the drive line. That's still just a D6 8/9U hub arrangement.

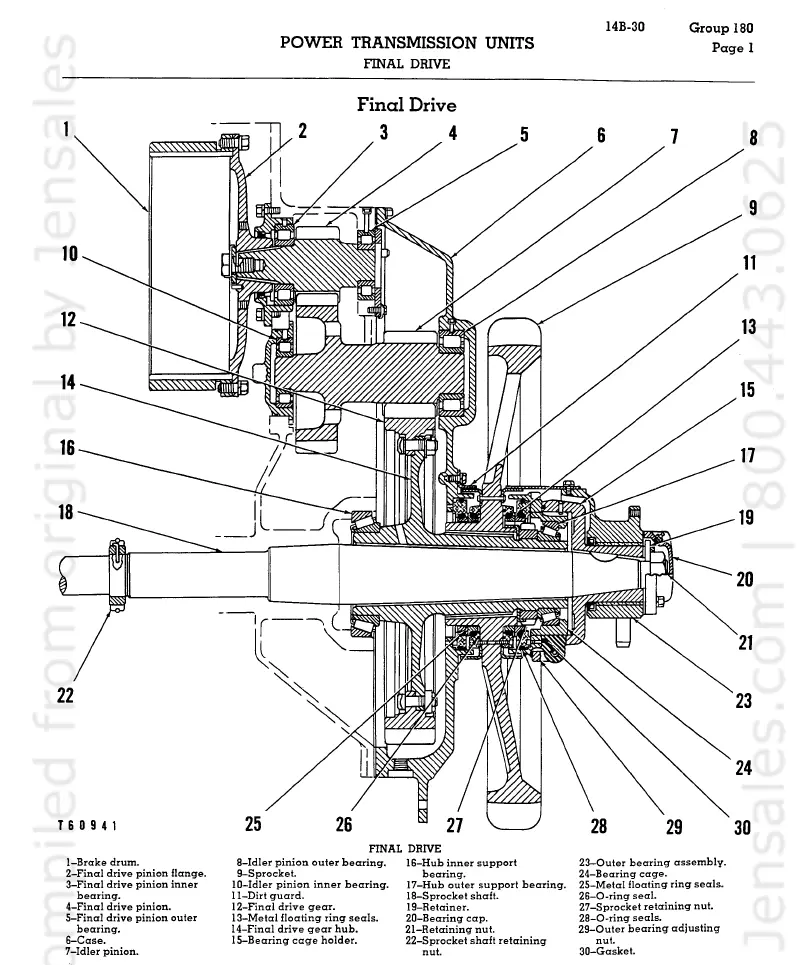

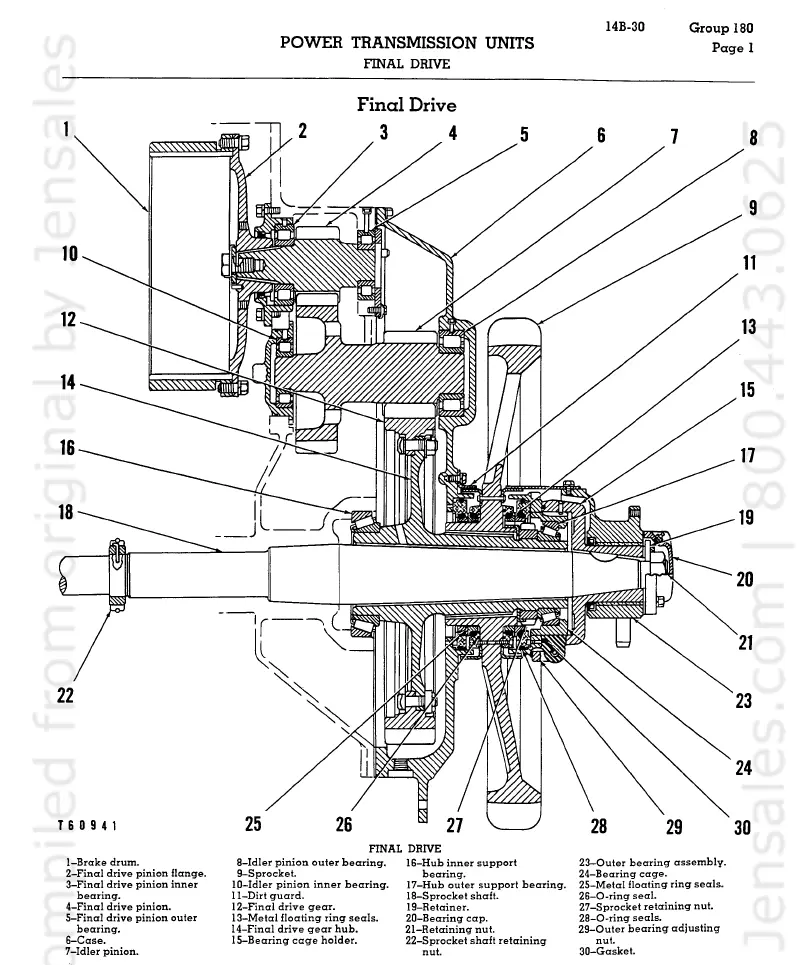

Copy that. While each clutch pack is out, is there anything else I can do without tearing things down much further? I don't want to get in over my head but I also don't want to skip anything that I can do reasonably easily while I am in there. Honestly, I am not even 100% sure of what the bevel gear hub is when looking at the diagram. Would you mind expanding on this for me? Thanks in advance!

[attachment=74832]Screenshot 2024-01-06 171211.png[/attachment][/quote]

What your showing is the final drives. I'm referring to what drives the finals through the clutches. For comparison the bevel gear could be described as the ring and pinion in a vehicle only in a tractor the ring gear/bevel gear is directly mounted to the hub ( no differential gearing)

I'd post a picture but I'm in the middle of transferring my files to a new computer and every things out of whack right now.

While your in there the steering clutch release bearings should also be checked.