Reply to ctsnowfighter:

50 years since I was a track press operator turning pins and bushings.

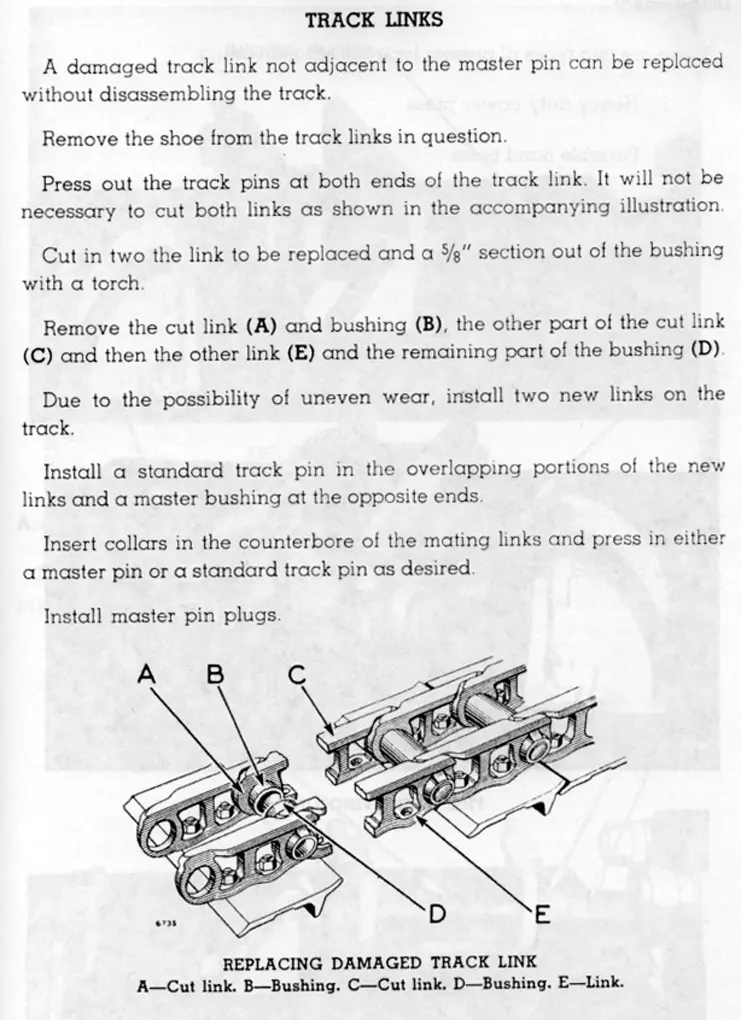

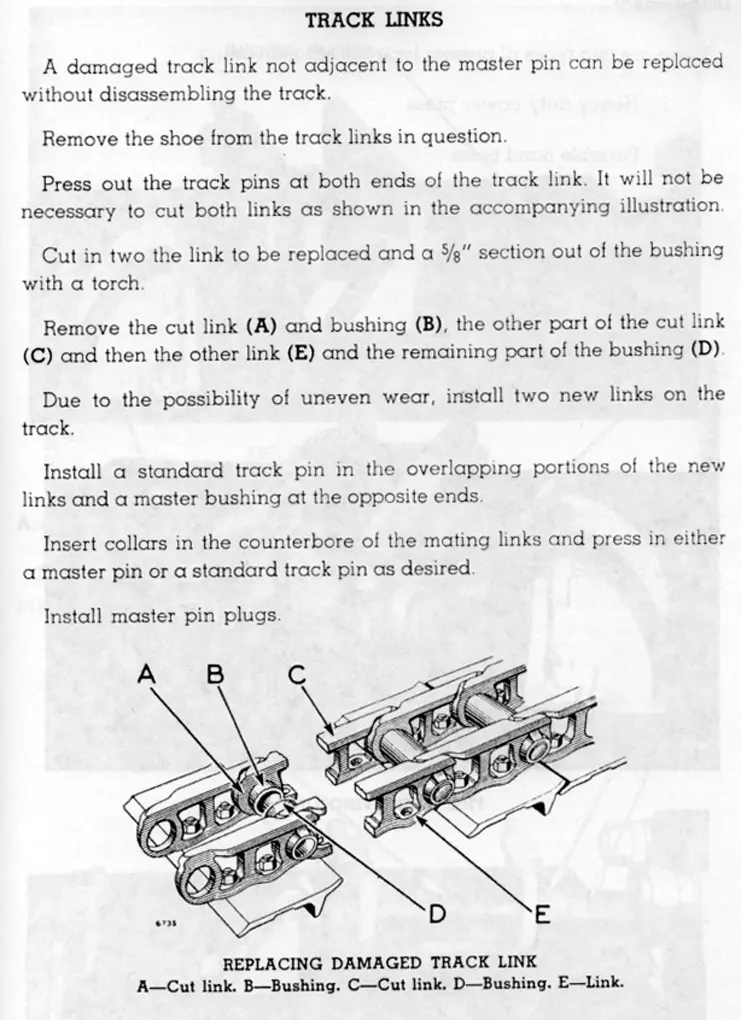

Memory serves correctly - all links except the master link are press fit, bushings to inside of the rail segments and pins to the outside portions, thus creating a chain.

Bushings on the master link hold the alignment of the narrow end of the rails, PRESS FIT! The pin on the other end of the "chain" holds the alignment of that segment of rail. Then the master pin is driven through the outer rail segments, a tight fit but not of the tonnage required for the rest of the chain pins and bushing.

This said - you can cut the pin/bushing with torch, cutoff wheel, etc but how are you going to remove the portion of the bushing in the rail segments?

Same goes for the pins. Those are tight fitting and require high tonnage to push out!

A broken link required total disassembly of the entire chain, just as turning pins and bushings. Not something that can be done with a sledge hammer and pin punch!

Sometimes one would install a second master link but that was not a common practice. Again - required total disassembly of the entire chain on a track press.

Typically, turning pins and bushings tightened the chains, but did nothing to the rail wear. It was a less expensive fix than new chains

CTS

[quote="ctsnowfighter post=250170 userid=9709"]50 years since I was a track press operator turning pins and bushings.

Memory serves correctly - all links except the master link are press fit, bushings to inside of the rail segments and pins to the outside portions, thus creating a chain.

Bushings on the master link hold the alignment of the narrow end of the rails, PRESS FIT! The pin on the other end of the "chain" holds the alignment of that segment of rail. Then the master pin is driven through the outer rail segments, a tight fit but not of the tonnage required for the rest of the chain pins and bushing.

This said - you can cut the pin/bushing with torch, cutoff wheel, etc but how are you going to remove the portion of the bushing in the rail segments?

Same goes for the pins. Those are tight fitting and require high tonnage to push out!

A broken link required total disassembly of the entire chain, just as turning pins and bushings. Not something that can be done with a sledge hammer and pin punch!

Sometimes one would install a second master link but that was not a common practice. Again - required total disassembly of the entire chain on a track press.

[/quote]

You are mostly correct except you can install a second master link without dismantling the entire chain. Seen ti done many times and have done it myself. As you know the only difference between a normal link and a master link other than the press fit is the length of the bush. The master link bush does not protrude past the edge of the chain and that is what you have to duplicate either with a new master link bush or by cutting the protruding bush flush with the link side. Heating the link half to get it back onto the bosh helps but you can also create another master link setup with it as well. Seen it done and lasted until the chain was retired many many hours later. If you have the adjustment then you can leave a link out and shorten the chain.

You are also incorrect about being able to remove non master links with a hammer and punch. I have also seen that done many times and as mentioned stubborn pins will require the link to be heated. Haven't seen it done on anything bigger than D8 chain though.

I don't understand why you would install a second master link unless you are joining two lengths of chain together WITHOUT dissembling the entire chain.