You have a wonderful day. Best wishes. Deas Plant.

Hi, bpusmc.

Whereabouts are you located? Even though I'm currently DowNunda in Australia, I know a man on the Central Coast, CA., who would just LOVE a challenge like that.

Are there any part or casting #s that you can find to help identify which pump it is?

Just my 0.02.

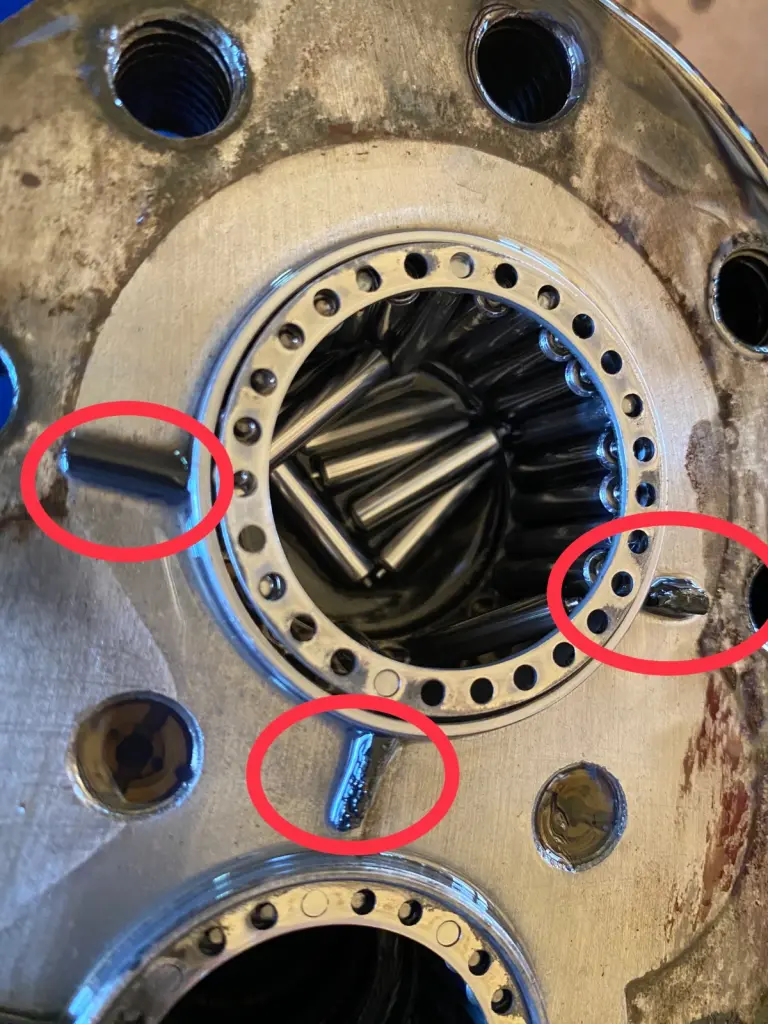

Thanks for your response Deas. I’m in central Texas. Here’s a few more pictures. [attachment=72887]IMG_7711.jpeg[/attachment][attachment=72888]IMG_7473.jpeg[/attachment][attachment=72889]IMG_7714.jpeg[/attachment]

You have a wonderful day. Best wishes. Deas Plant.

Hi, bpusmc.

I have just sent this man an e-mail with a link to this thread. It will be up to him whether he takes it up or not. He has worked in spare parts for about 25 years and recently got me some parts for equipment on the ranch in California that the local dealer had on a month's back order.

Just my 0.02

Thanks a million Deas.

You have a wonderful day. Best wishes. Deas Plant.

Hi, bpusmc.

Let's see where it goes - or if it even gets off the ground - before you go 'spending a million thanks'.

Just my 0.02.

Hi Chad, if the OEM parts aren't available, as an alternative, you might be able to match those bearings dimensionally, and have someone turn down a new plate for you

Because that is a non-Cat pump, it might be cheaper to replace the whole pump. If you do that you need to know what pressure the cylinders are rated for and find a pump to match.

Because that is a non-Cat pump, it might be cheaper to replace the whole pump. If you do that you need to know what pressure the cylinders are rated for and find a pump to match.

I have a very similar if not the same pump on a 9u D6. It had been sitting 20 years plus on a farmer built pruning tower for walnut trees made to mount to a IH TD 14 tractor. It leaked around the input shaft. Was a very simple to fix lip seal used in hydraulic applications. Unlike the spring loaded seals in the lower pressure Be Ge unit it replaced. The shop had one on hand, and very cheap too as I recall. I am thinking mine has O rings rather than a gasket. I don't recall ever having a pressure gauge on it but would guess 1400 to 2000 PSI. Lifts implements a Be Ge struggled with.