Hi Bernard, there is a thing called a "penny", they do come in different sizes to match the fitting you have to plug, just remember the fittings have different diameter and thickness where crushed inside the lip of clamp, for example a 61 and 62 series (61 is thinner than 62 but same diameter). that is what we would use here is Aus

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

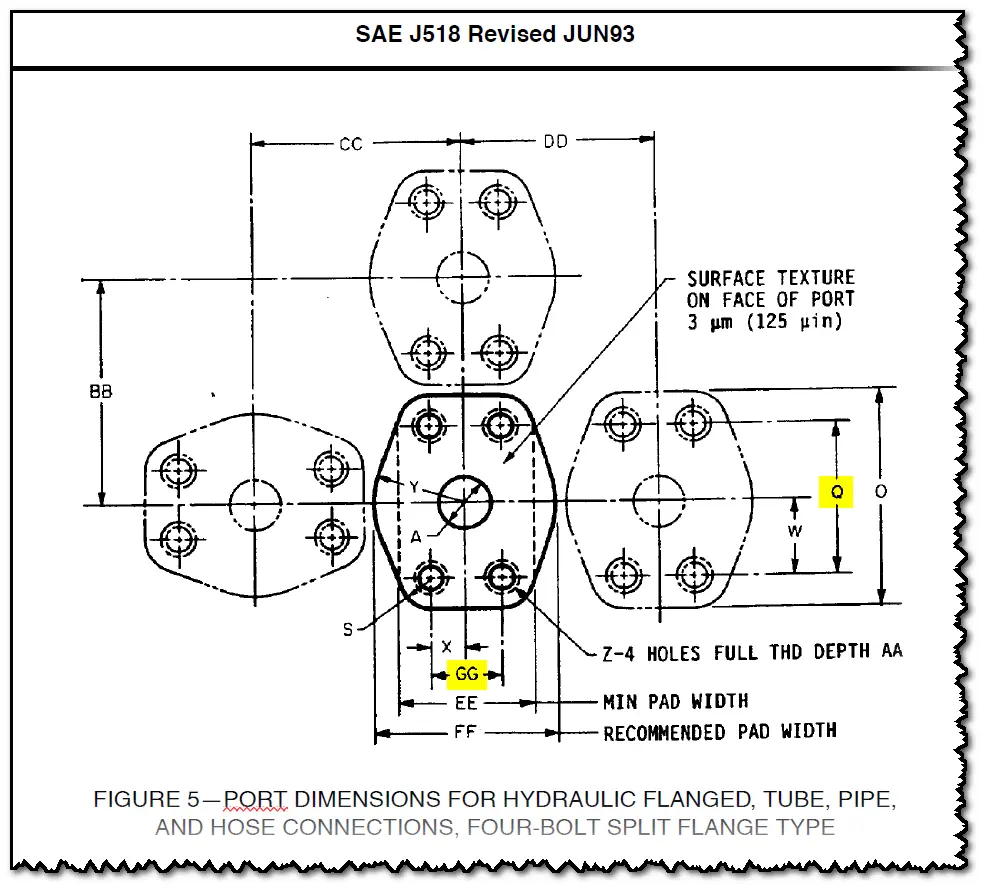

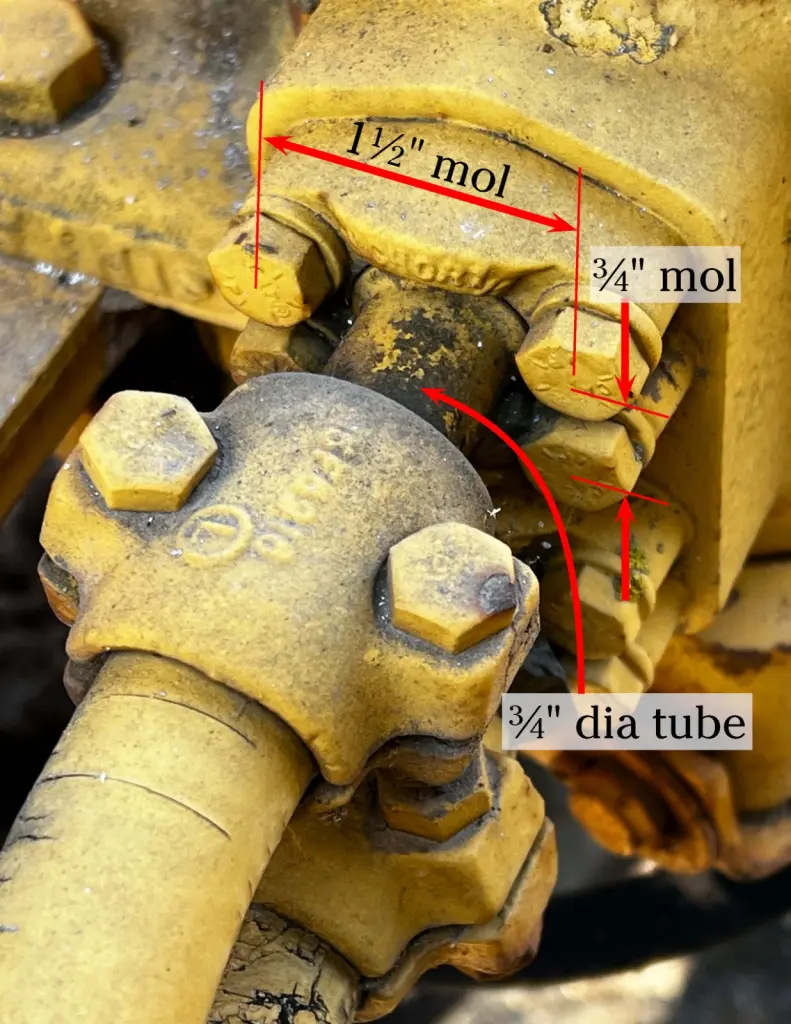

they are sae code61 fittings. any hydraulics shop has them. the hose you use with those is sae R100a2 spiral wire hose. most of those fittings used on cats back then are dash 12 size so that is 3/4 internal dia. a dash is a 16th of a inch.

note there is a difference in the current cat code61 fittings, the flanges are thicker and need a spacer if you mixing genuine cat clamp plates with aftermarket hose ends. the classic machines didnt have this difference though. just be aware of it if you buy new stuff from your dealer it has that difference. they are oring sealed dont reuse the oring fit new one when you disturb them. blanking plugs are available. i wasnt aware of a difference till the hydrualics bloke asked me was it old stuff or modern when we had a hose replaced.

oh and heres a tip with the rams if the shafts are worn, damaged or pitted dont bother recroming the rod its cheaper to re-rod them. we had the a pair of rams rebuilt with rods custom made, the machinist reused the pistons and rod ends and assembed em with new seals it cost under $900aud. we were quoted $700 just to rechrome one rod.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

ryco, parker hannefin, and gates all do fittings for code 61 and 62. adapters are also available. those are field replaceable. provided the fitting isnt damaged they are perfectly safe just fit new grade8 bolts when you fit new hose.

these old girls didnt work over 1500 psi that why the rams were so large.(bigger piston surface area means more power for the same driving pressure)

all you need is a grinder with thin cutting wheel, a hacksaw, a bench vice, bearing grease a couple of spanners, a mallet, patience and elbow grease.

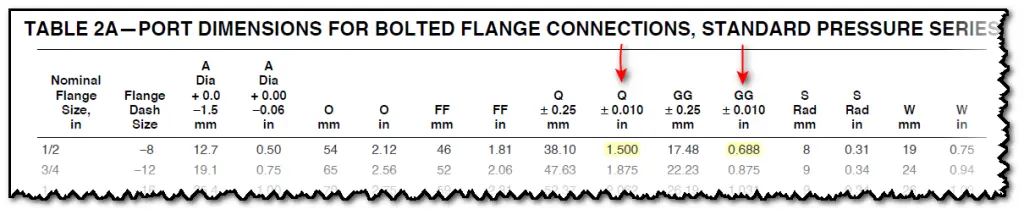

If you have measured correctly as per your image then that is not a -12 but a -08 which has a hole spacing of 1.5" x 0.69.

Your better off replacing the hose with a new crimped hose rather than trying to refit a new hose.to the old fittings.Not all hydraulic shops carry the flange type hose tails and you may need to either get them ordered in or use adapters.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

i spelled the hose type wrong its sae 100r2at. and yes dash-8 is the other common size which is 1/2 inch bore. yes crimped or wind on fittings are better than clamp on. thats why with the conversion im doing i have used wind on type jic fittings and code 61 adapters. it allows me to change the hose with out special tools if i need too. and available anywhere.

did you measure internal or outside dia? all pipe and fittings are measured internally the exception is metric"blueline" polyethylene irrigation pipe it is measured od just to be different.