I do not remember CUTTING the rim in half - think I used the new rim to mark the cuts on the old spokes. Wonder if a portable Milwaukie band saw would work to make all the cuts on original sprocket??

I did my 941B rims that way--also didn't have to cut the new rims in half--used them to mark the old spokes and gas cut them making sure they were on the long side and ground down the cuts to fit the new ones on--this was about 25 years ago and no cracks yet in the welds

Well, the cutting-in-half is to avoid removing the track frames which is a pretty big job for my buddy. If he could avoid that and get a decent result with fitting the rims, that would be preferable.

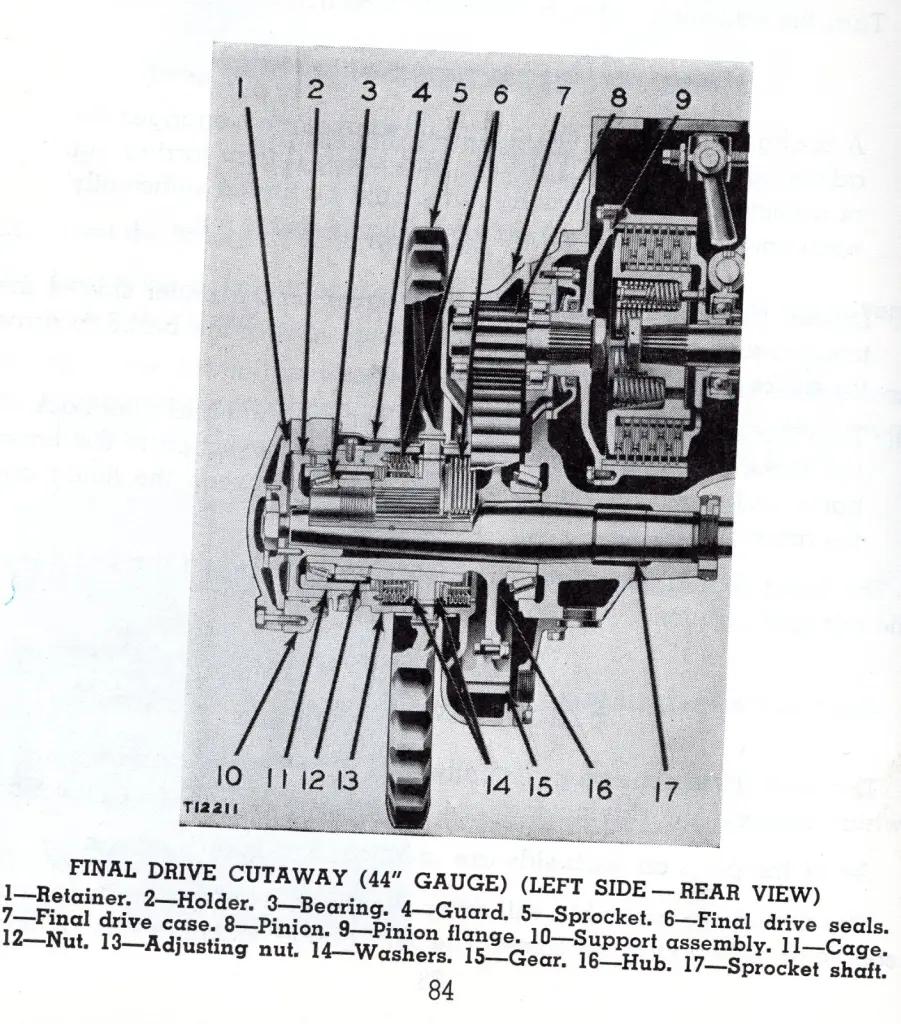

Is there any chance removing the outer bearing and unbolting the cap from the frame lifting that side a bit - would give you enough room to slip the new ring in after cutting away the old??

I believe rather than cutting in half, you cut out a sufficiently large enough section to be able to slip on without removing the track frames, this makes it easier to realign correctly when joining as well as marking out the cut on the old sprocket.

Regards, Wombat.

restore49, I don't know unfortunately as I've never been down this road before, but if someone has, it would be good to know how much effort was involved.

Wombat, that's a great idea since it would reduce the risk of misalignment. I might make a mockup out of plywood to see how well it would work

somewhere i read about that procedure--much easier to align a 90 degree or less section of rim rather than a 180 degree section

With the Bearing Cap Assembly removed may be possible to get the cut ring out and slant slip the whole ring in.??