More likely to be a problem with the lift cylinder/s than the control valve.

Thank you for the reply Old Magnet, I thought the same and had both cylinders rebuilt at a cost of around $800.00, but it did not change anything, but on a good note my scarred cylinder rods were replaced. I was hoping there was a defective/ineffective check valve between the two cylinders that failed, but I am having difficulty finding diagrams of all the components in this hydraulic control, or I guess the understanding of it.

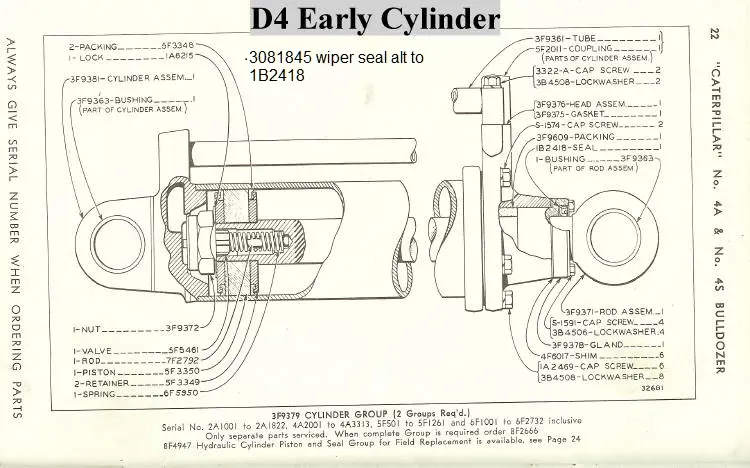

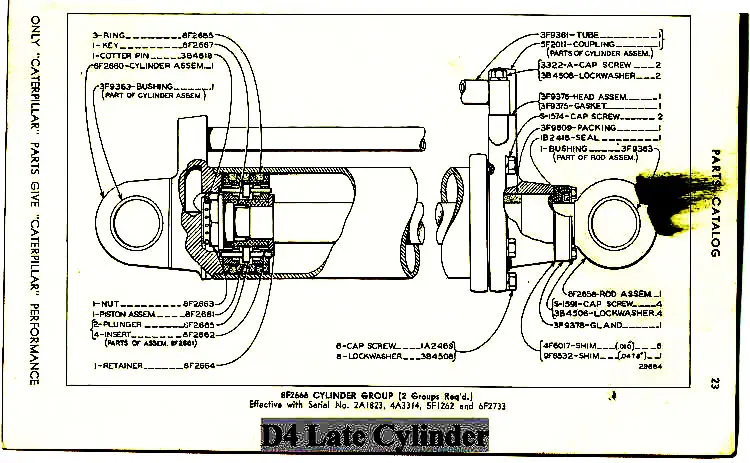

Which cylinders do you have, early or late?

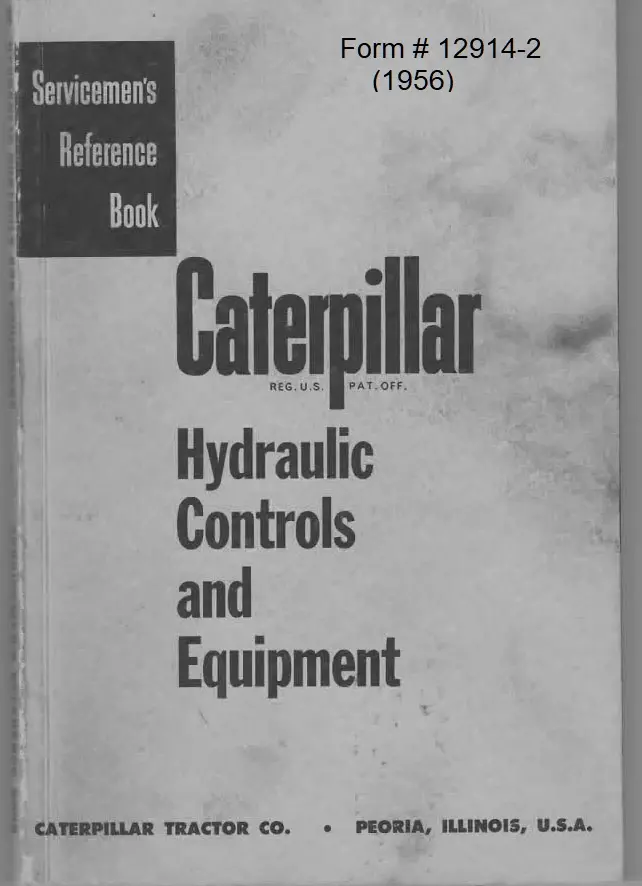

You need this manual for the #44 control.

[attachment=68300]D4 Early Cylinder.jpg[/attachment]

[attachment=68301]D4 Late Cylinder.jpg[/attachment]

[attachment=68302]Hydraulic Control Repair Manual.jpg[/attachment]

If it is a straight blade with a fair amount of slop in the linkages then what you are describing will happen, as the cylinders are somewhat independant of each other due to the slop, and the oil will follow the line of least resistance first.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

we had bushes turned up for the rams because of the play. also is your blade set square ours wasn't and it would dig more one side. you are aware there is a float position on the valve control. are you sure your not putting it in float.

how are the cutting edge worn? turn them over to get extra life if they haven't been turned already. the easiest is blow the nuts off with the hot spanner and fit new bolts they are a standard 5/8 plough bolt cant tell you what length been too long since we did ours. you always want cutting edge below the blade itself. cat still has a listing for the cutting edges.

is the pump making a lot of humm noise if so it may need bleeding which is easy cycle the rams full stroke each way a few times also top off the oil in the reservoir if that makes it better that was the problem. if after bleeding the humm quietens then low oil and entrapped air was the issue. if its really bad or doesnt get better the pump may be worn. parts are available but you need a spare kidney to pay for them. Vickers is now part of Eaton hydraulics. bleeding is basically the same as bleeding the power-steer on your vehicle

what oil are you using?

It appears that I have the late cylinder on my D4, and thanks for the suggestion as to reference material I will check it out.

we had bushes turned up for the rams because of the play. also is your blade set square ours wasn't and it would dig more one side. you are aware there is a float position on the valve control. are you sure your not putting it in float.

how are the cutting edge worn? turn them over to get extra life if they haven't been turned already. the easiest is blow the nuts off with the hot spanner and fit new bolts they are a standard 5/8 plough bolt cant tell you what length been too long since we did ours. you always want cutting edge below the blade itself. cat still has a listing for the cutting edges.

is the pump making a lot of humm noise if so it may need bleeding which is easy cycle the rams full stroke each way a few times also top off the oil in the reservoir if that makes it better that was the problem. if after bleeding the humm quietens then low oil and entrapped air was the issue. if its really bad or doesnt get better the pump may be worn. parts are available but you need a spare kidney to pay for them. Vickers is now part of Eaton hydraulics. bleeding is basically the same as bleeding the power-steer on your vehicle

what oil are you using?

Check for either a 3F or 8F number stamped on the cylinder if your not sure which one.

Both cylinders run off a single circuit in the hydraulic control, sort of either it works or it doesn't.

Ok, it is a definitely a later model cylinder because it has an 8F number. The one important fact I didn't previously mention is that when I am using the blade, I can literally see either one of the cylinders fluctuating in movement of up to 3 inches with any kind of resistance, So, would you put that into the "worn hydraulic control" category?