Hi,

we used to oxy cut the roller cage to remove the rollers, carefully set the shaft on end and heat the bearing inner race with an oxy torch using a largish cutting tip to get heat into the race quick before it soaks into the shaft--if you have done it right the race will drop down by gravity.

Cheers,

Eddie B.

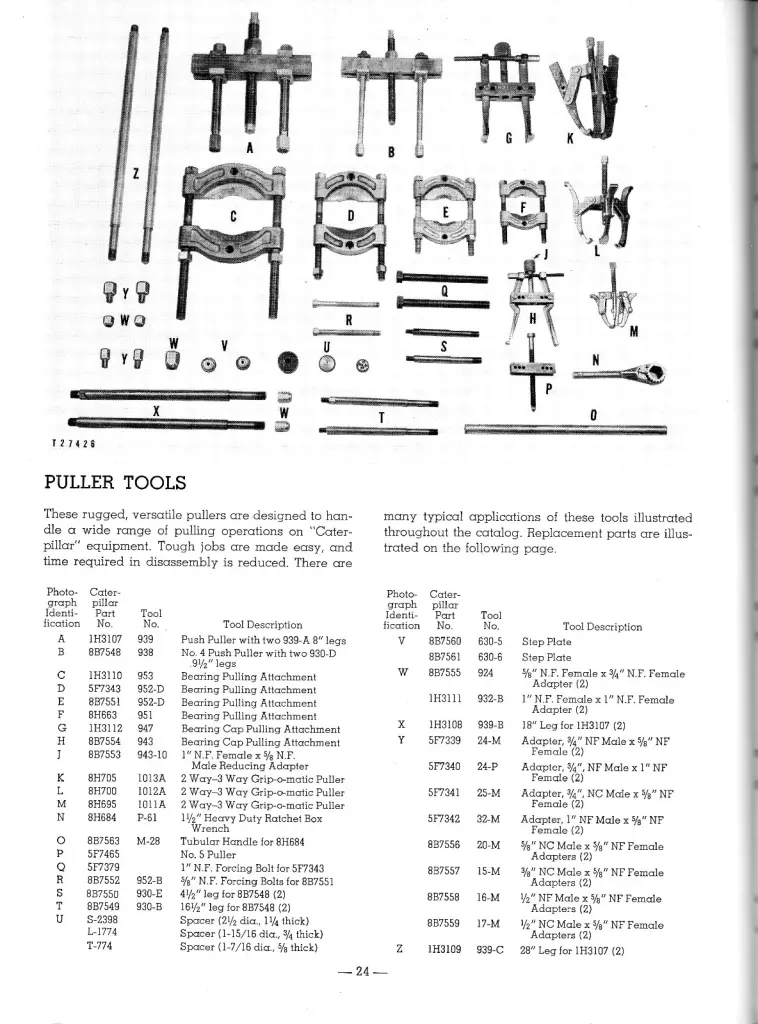

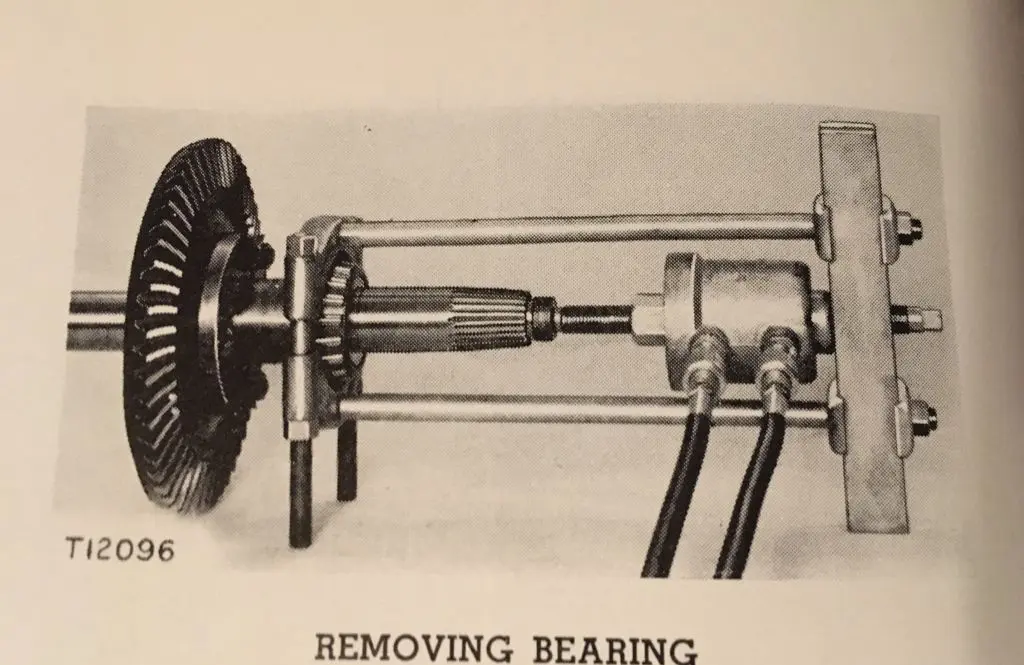

Edit--added some tooling I have used in the past at the Dealer for pulling such items but it is time consuming to set up and use.

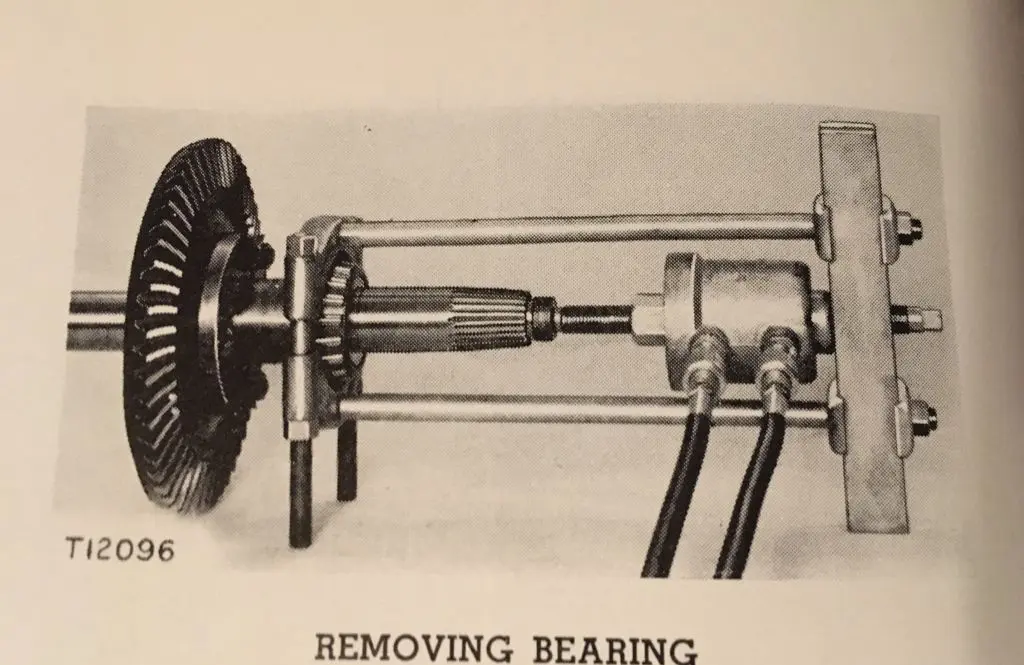

Is this the picture you want?

edb, Thanks for the scan!

Josh, I was able to get bearing puller on the bearing away from gear, the bearing that is pressed to the back side of gear doesn’t have room for a traditional bearing splitter. I ended up having to make some jaws.

Fine business on the D4 pushing and pulling wisdom. We have two Twenty Twos and a Fifteen with bevel gear shaft endplay. Is there a way to remove the bevel gear shaft bearing inner races without pulling the shaft out of the bevel gear? Are there any tricks to reduce likleyhood of breaking the clutch drum? Also, how does one know when the bevel gear pressed far enough onto the shaft? If one is faced with some likely steering clutch, final drive and transmission rehab and considering investing in a shop press shall we aim for a 20 ton, 40, 50 or more? We located an older Fanco (Nugier) 40 ton and are looking at a Harbor Freight press. We have a well used 12 1/2 ton H frame and a 30 and 50 ton OTC puller set. Any thoughts would be greatly appreciated!