Hi d2gary,

I just went back the other way dry to oil (oil originally),

1 you have to split the engine from the gear box dont forget to undo oil pickup as it is bolted to the g/b housing and oil clutch housing

2 remove old oil cluch housing

3 remove and replace flywheel

4 remove and replace arms on top g/b housing

5 install clutch pivot

6 install bottom pin for other clutch pivot arm

7 install dry clutch components as there is no side hole to tighten bottom bolt on clutch yoke (mine was welded)

8 reinstall engine

9 adjust all linkages

10 hope it works

In simple words not easy

Hope this helps

Regards

Hi d2gary,

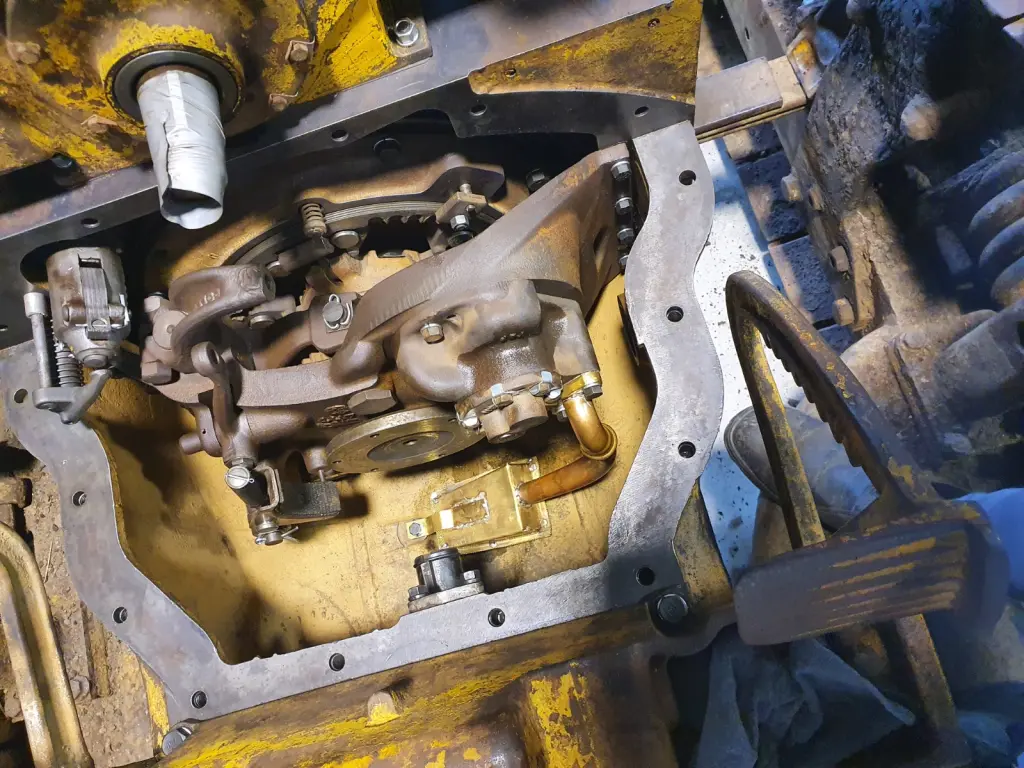

here are a couple of photos of the oil clutch,

[attachment=65051]20210128_182236.jpg[/attachment]

[attachment=65052]20210128_172340.jpg[/attachment]

[attachment=65053]20201231_194452.jpg[/attachment]

[attachment=65054]20210107_210053.jpg[/attachment]

regards

Just like we were discussing regarding the forum upgrade thread. The oil clutch "upgrade" was a giant step backwards.

There is nothing wrong with the dry clutch setup. The parts are so robust that it will never wear out if maintained properly. It is just difficult to adjust on the D4. If they had made it like the D2 with the button instead of the clamp bolt it would have been better.

I knew a guy who sent his D4 in to an independent shop.and it came back with an "oil clutch". I don't know if they used a different clutch disk but they just dumped oil in it.

Thank you for the pictures rax200, I was looking through the servicemen book and what I was seeing didn't look like what I saw through the inspection cover. The pictures you posted look like whats in my book and the actual clutch l have looks like a standard dry clutch. The case is definitely a case that started life as an oil clutch. Like 8C 361 said I think someone just unknowingly filled it with oil, kinda like I did. I never had problems so I just topped off the oil. This will make my job a lot easier since I have a parts tractor with a complete clutch assembly with good linkages.

Thank you for the information

I don't know the history of this machine so I can't say if someone changed the disc to a different material or if it's just the standard dry disc.

I've never experienced any slippage or other problems with the oil in the clutch compartment. The tractor doesn't get a lot of run time so maybe extended run time might show more symptoms. I did use the Cat spec oil but I don't think I would chance it on any of my machines. Not to mention the oil really stinks and it's not cheap.

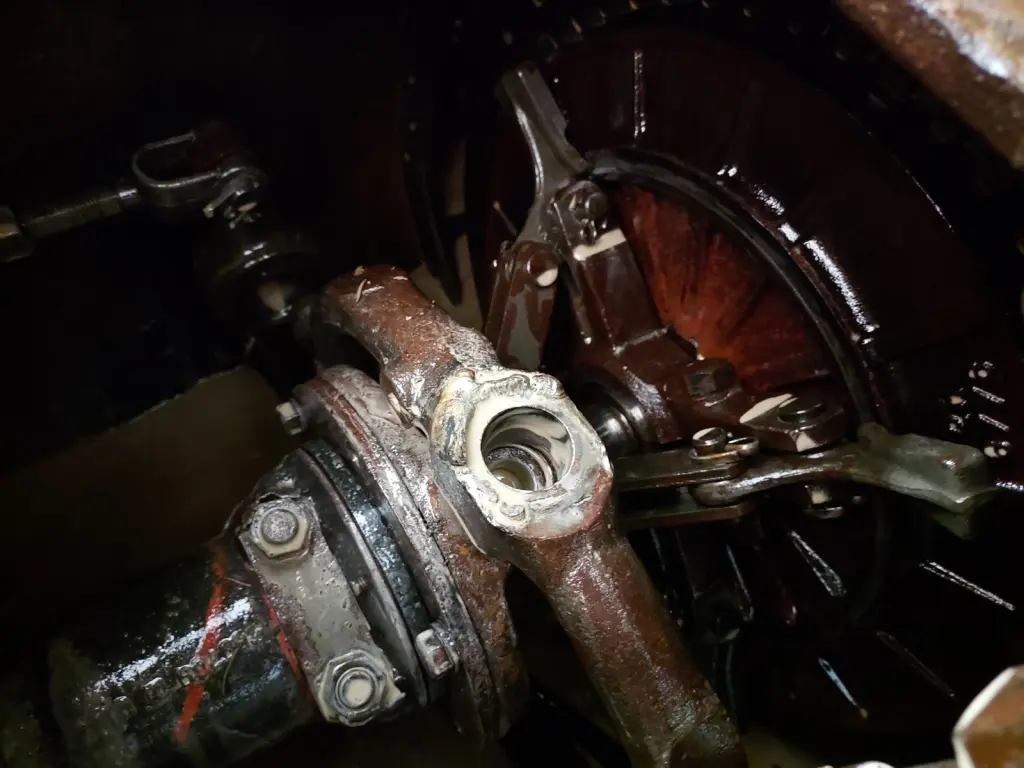

I got the inspection cover off and found the top bolt in the yoke is pretty hogged out and has been welded in. I feel like the bottom bolt , that I suspect fell out, will have the same treatment. [attachment=65061]20211013_094746.jpg[/attachment][attachment=65062]20211013_094759.jpg[/attachment][attachment=65063]20211013_094724.jpg[/attachment]

Those are great photos of the clutch Daryl - even the boots!

I'd love to know how running oil in a normally dry clutch changes performance (life, clamping etc). Fascinating.

Paul.

Hi Scott, If your dry clutch works fine with oil in it, then I'm going to look hard at doing that too. Have you pulled hard with it?