Hi Richard,

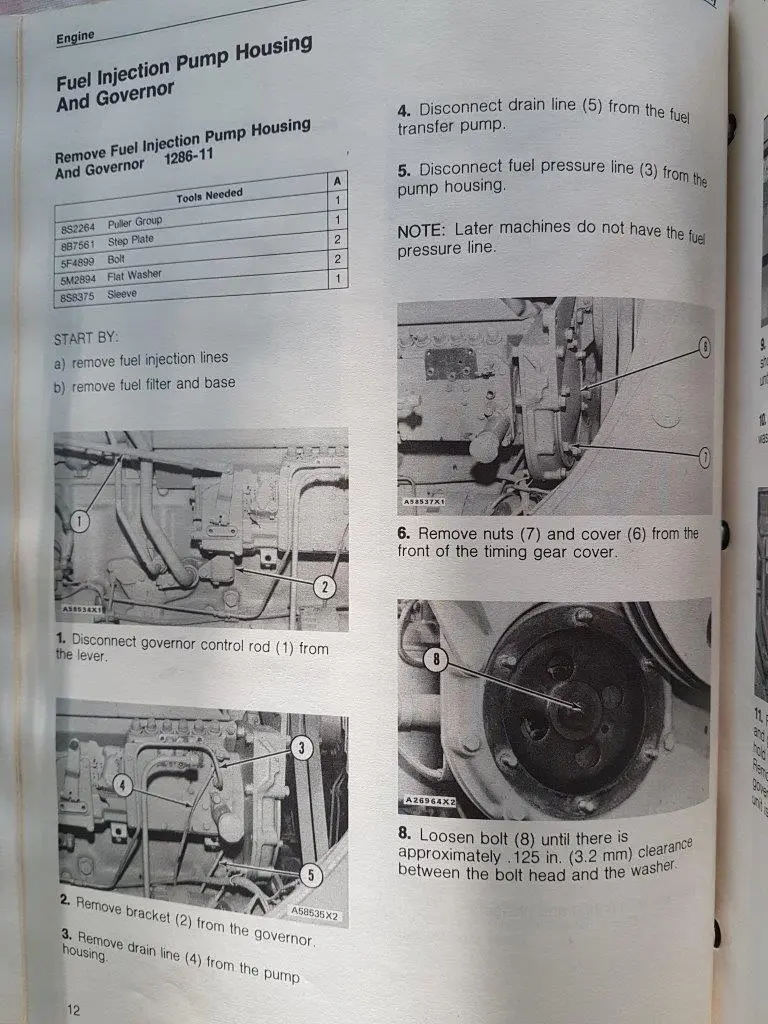

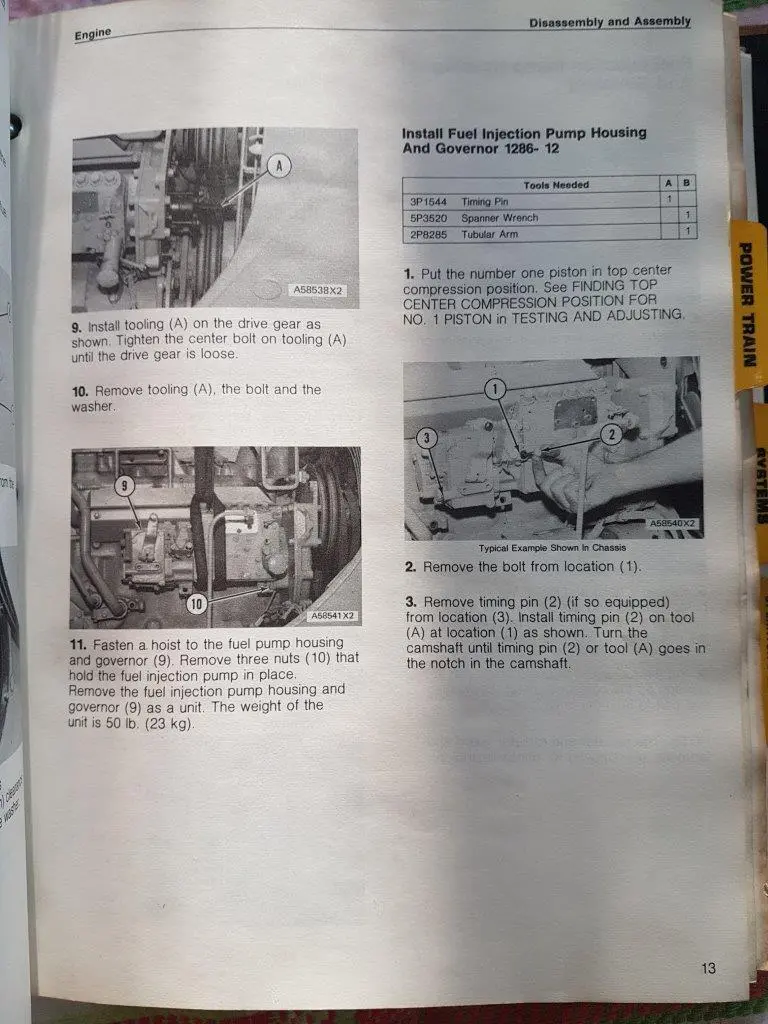

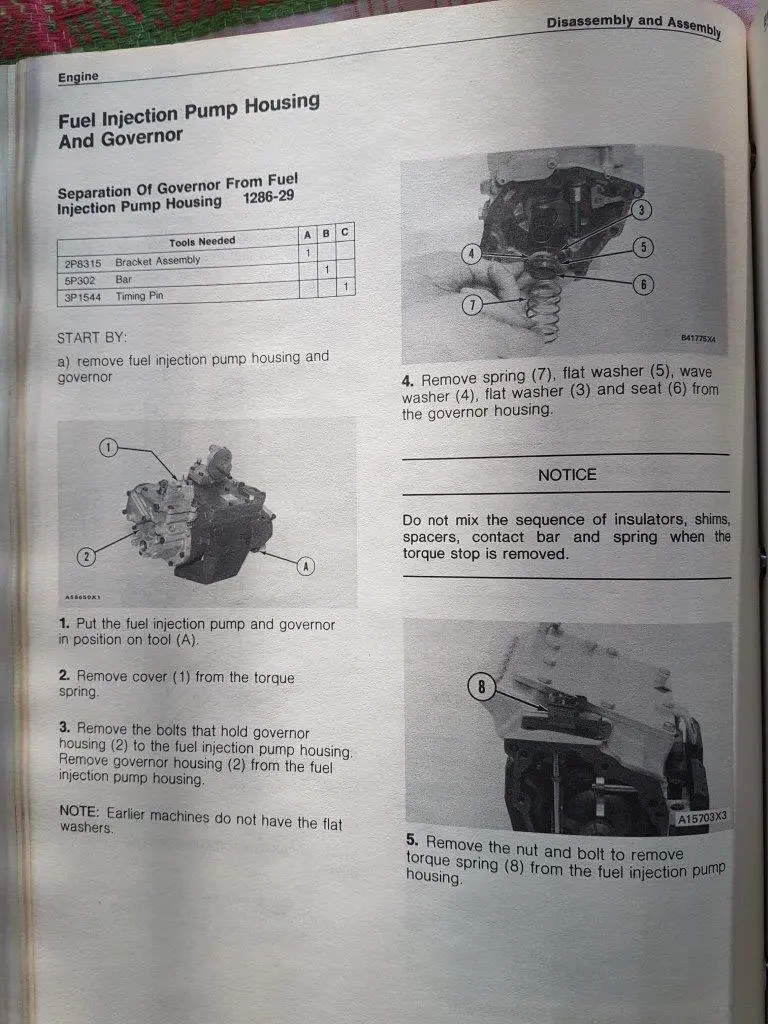

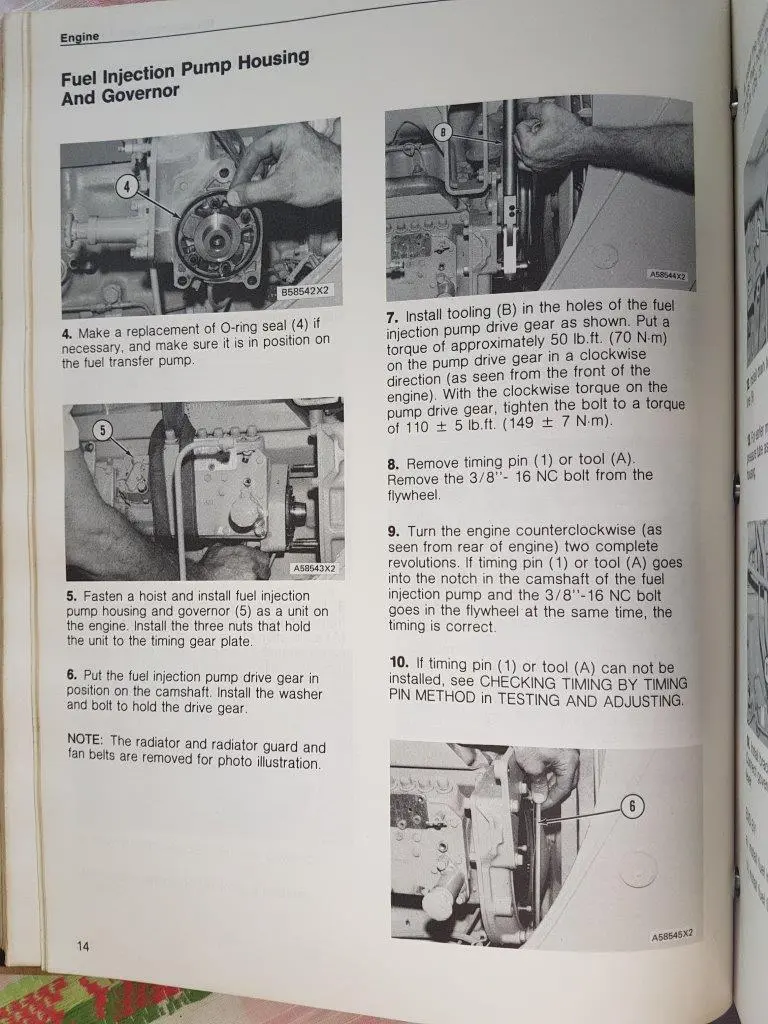

Not sure if the PDF will attach--it has details of assembly etc. for a 3304 engine--3306 is same but 2 extra pump elements.Been some 20 years or more since I worked on these so will try and answer your queries.If this does not help please ask again.

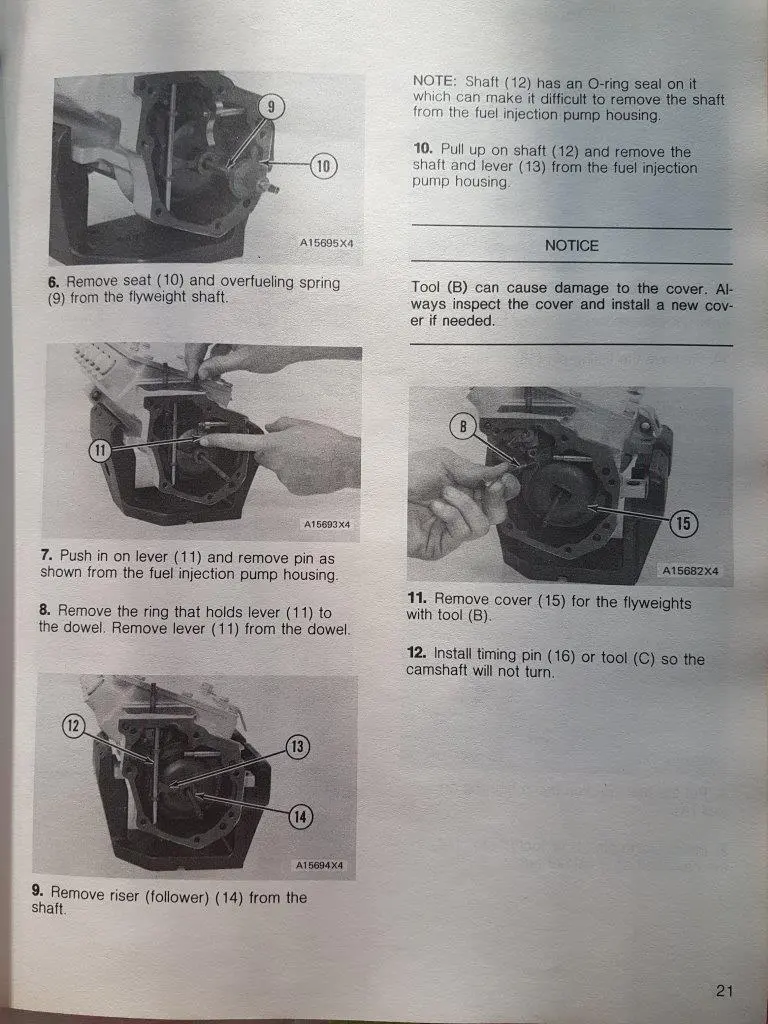

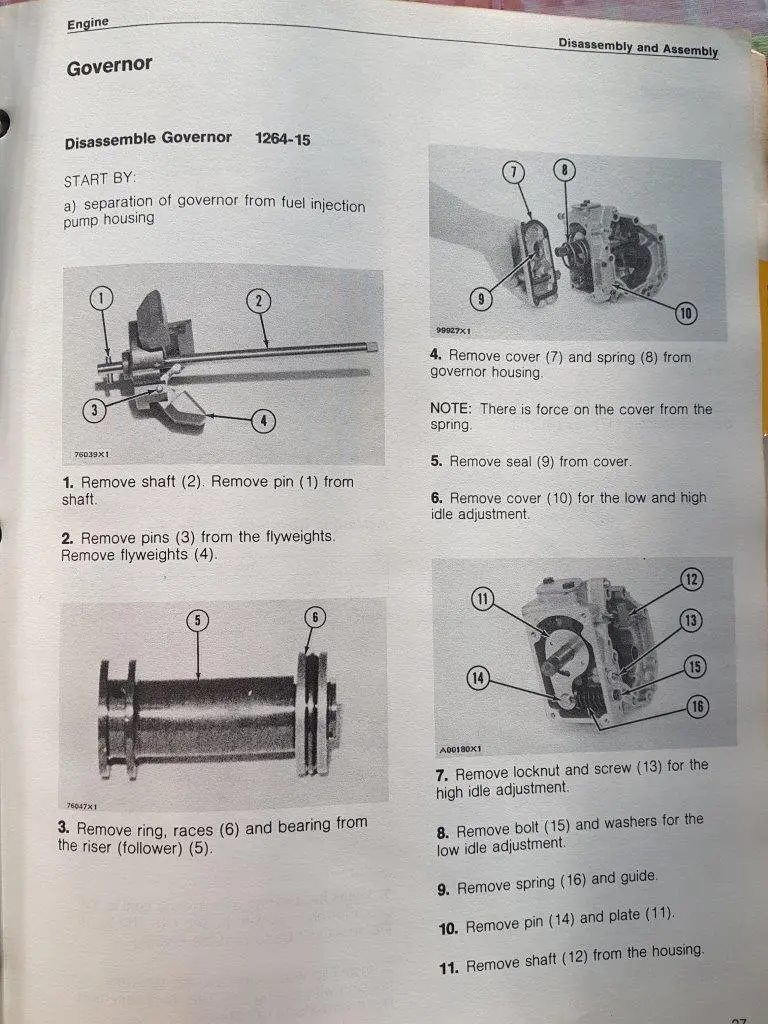

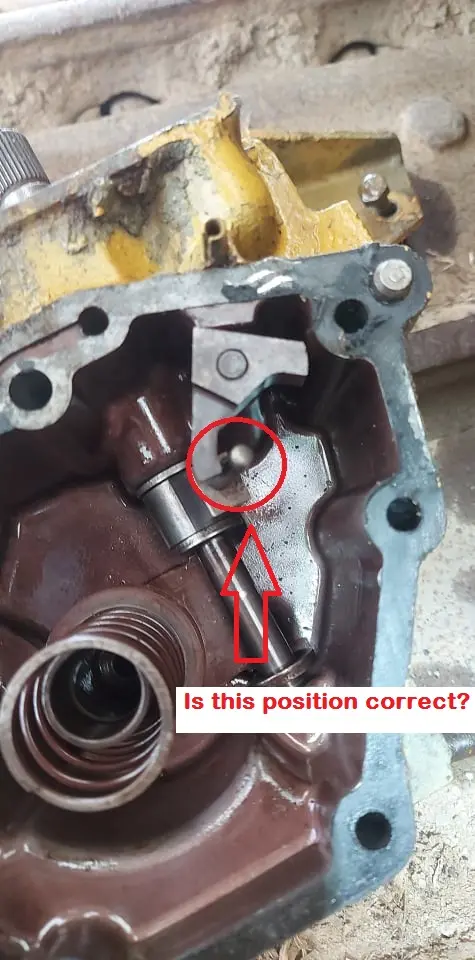

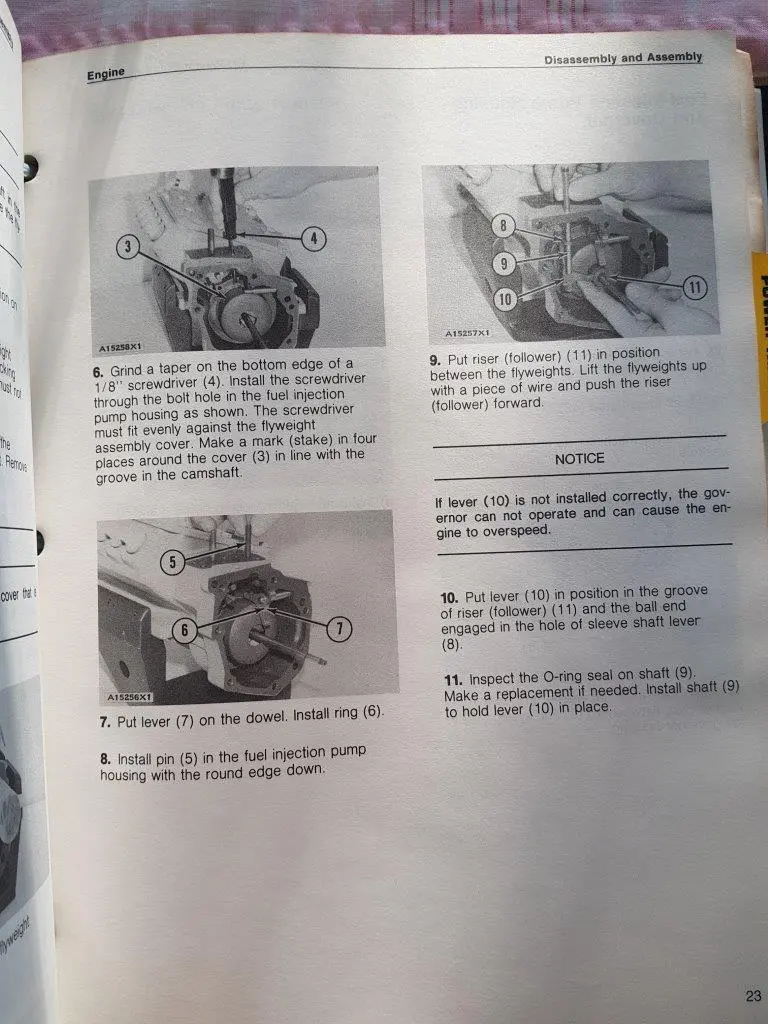

Pic 1,

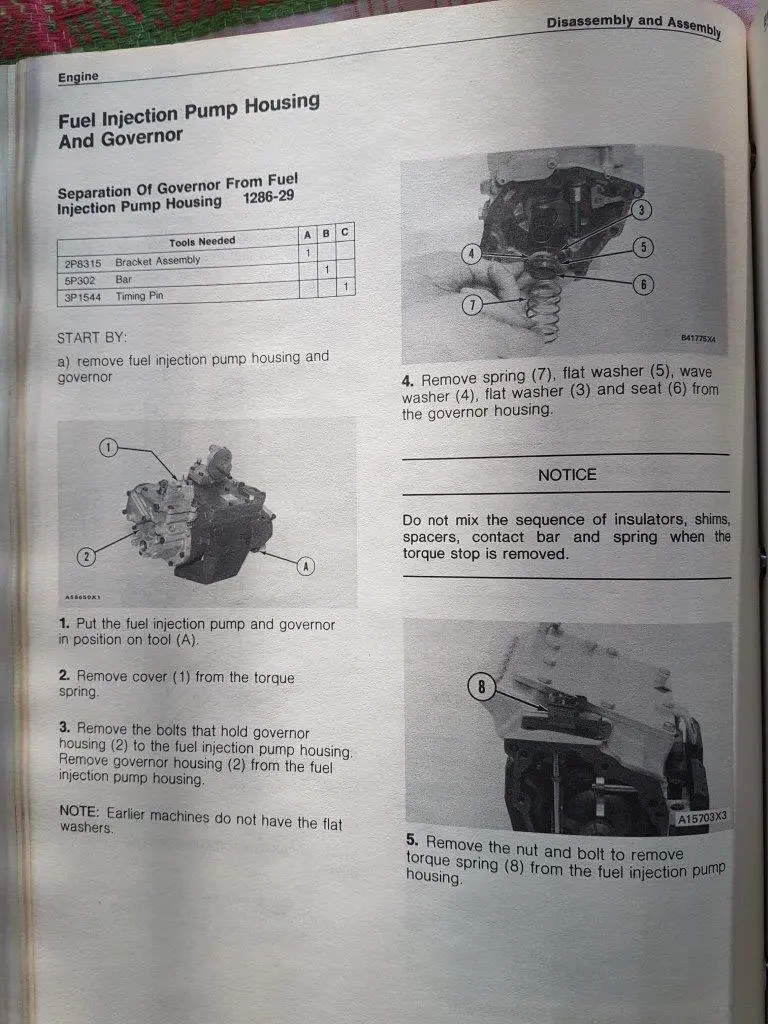

the centre piece is the shutoff detent and works in conjunction with the low idle and high idle stop screws--with the spring pressure the two side plates crush against the slug on the centre piece--the slug works in the groove for normal operation and is forced back between the plates in the stop position--it gives the detent stop feel.

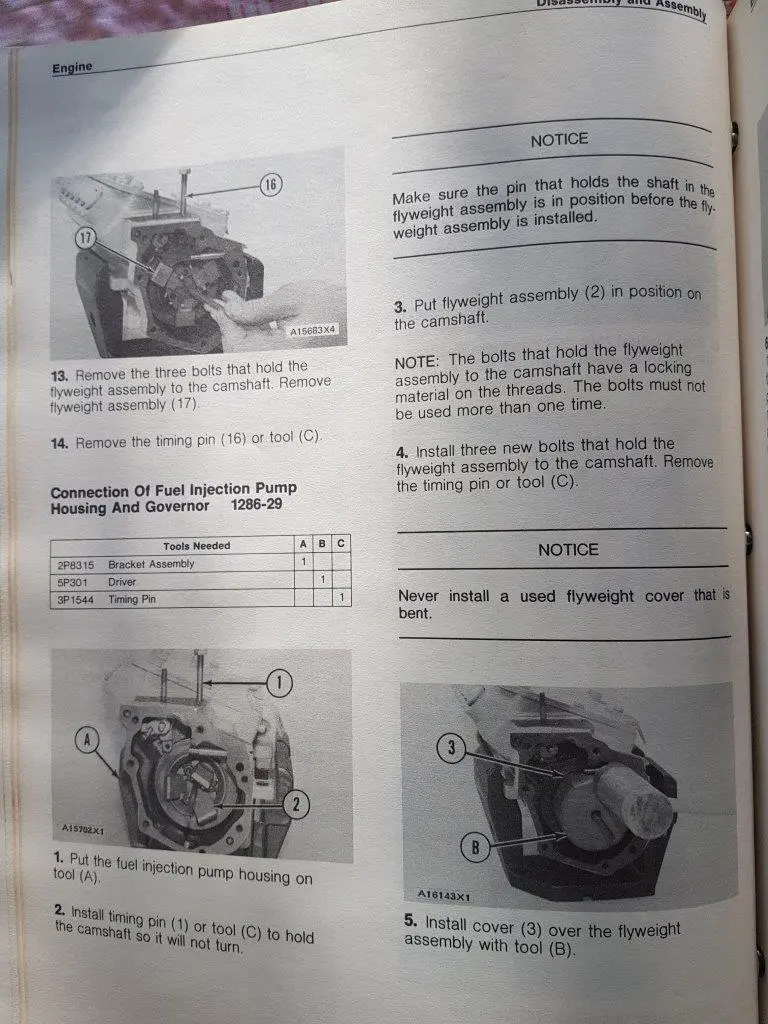

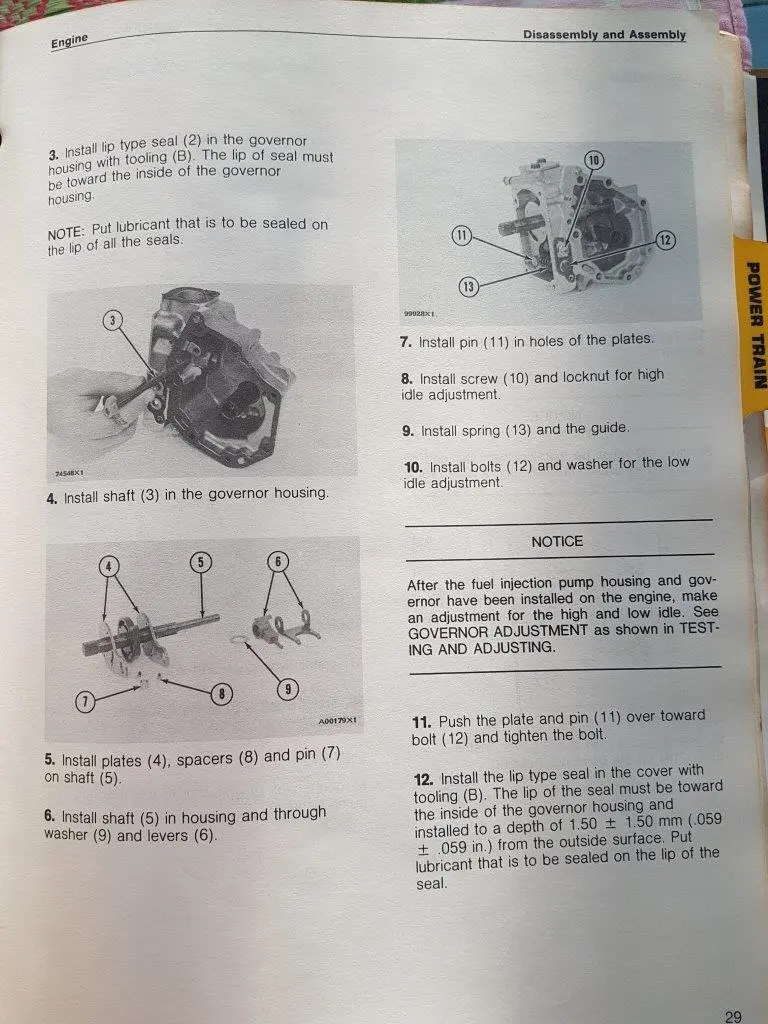

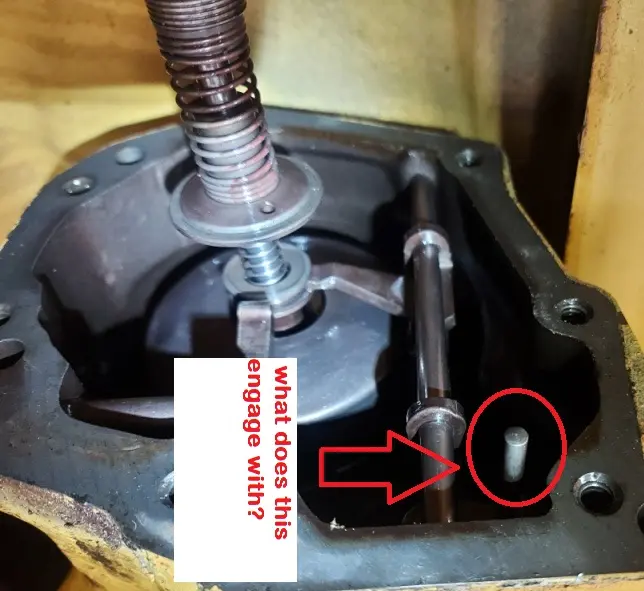

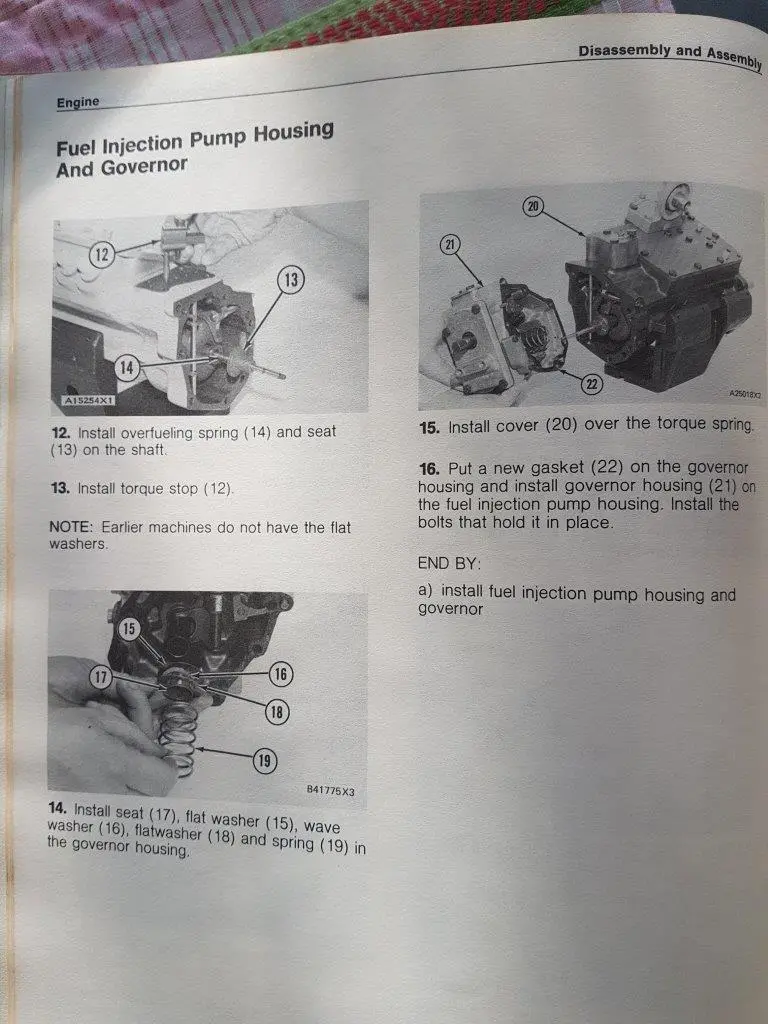

Pic 2,

the springs shown are correctly orientated for position.

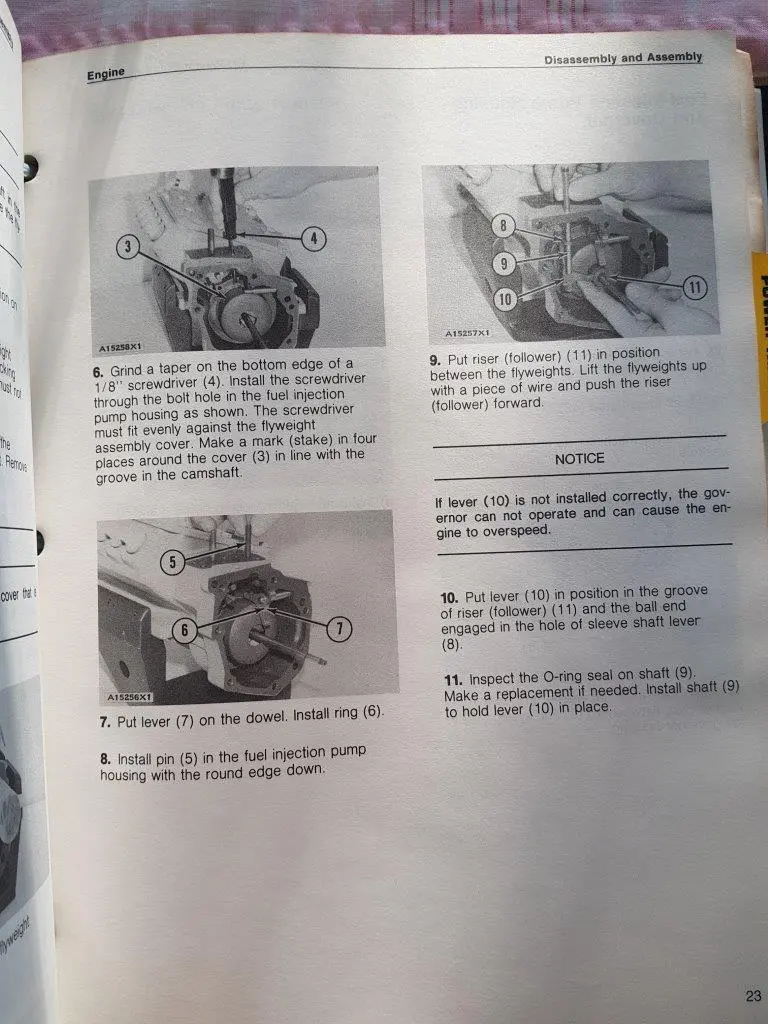

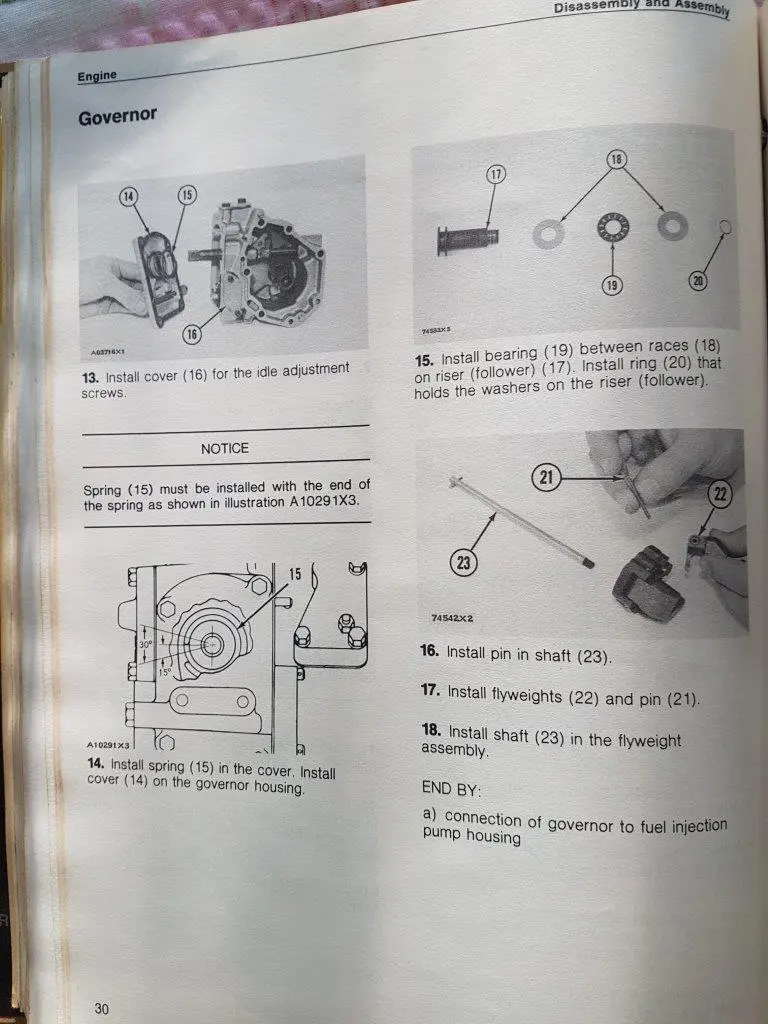

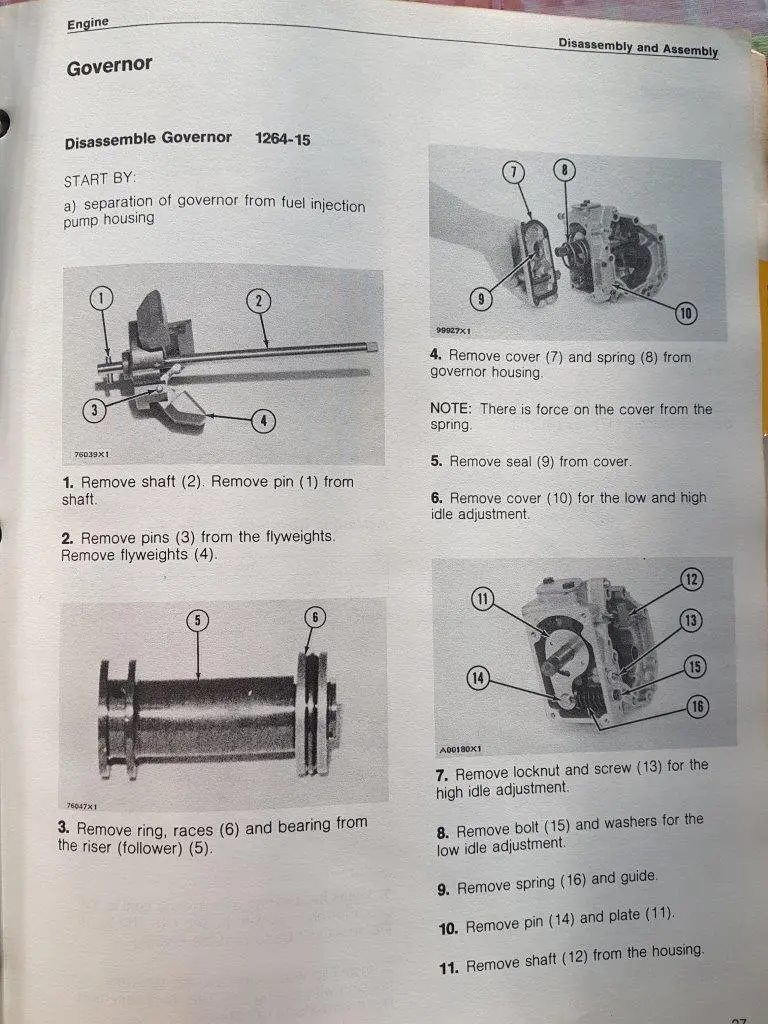

Pic 3

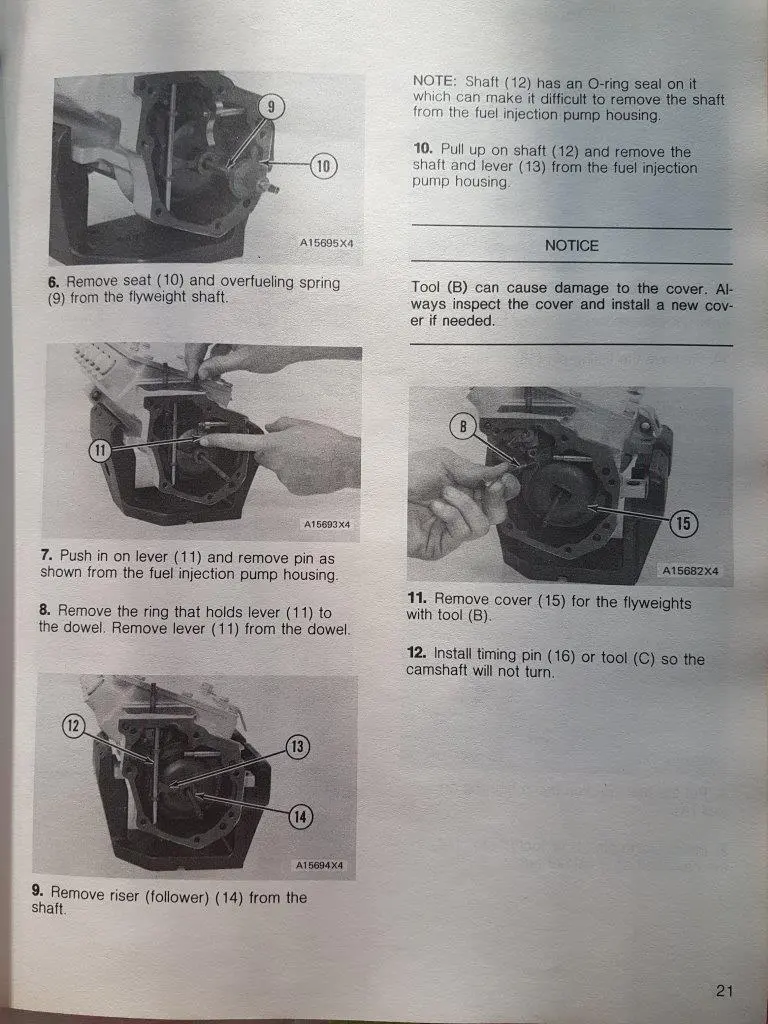

,the pin is in its correct location when that lever with the pin is engaged to the slot in the control shaft, the pin and the other double end lever is to limit the rack opening as dictated by the Air Fuel Ratio control cylinder and its setting.

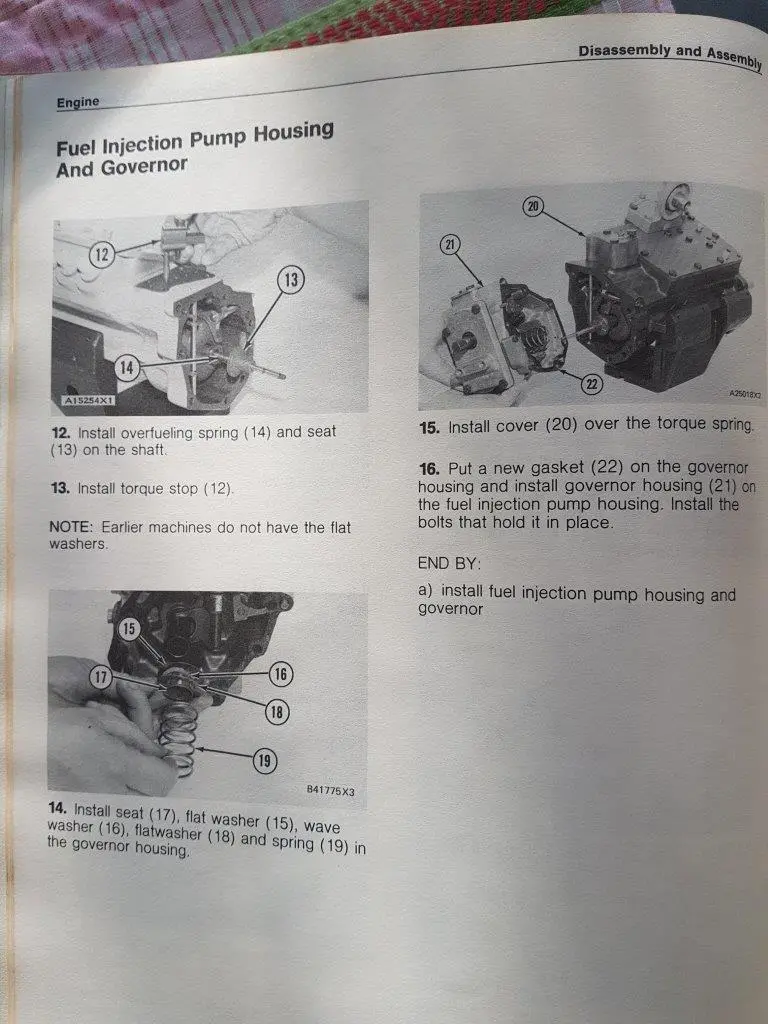

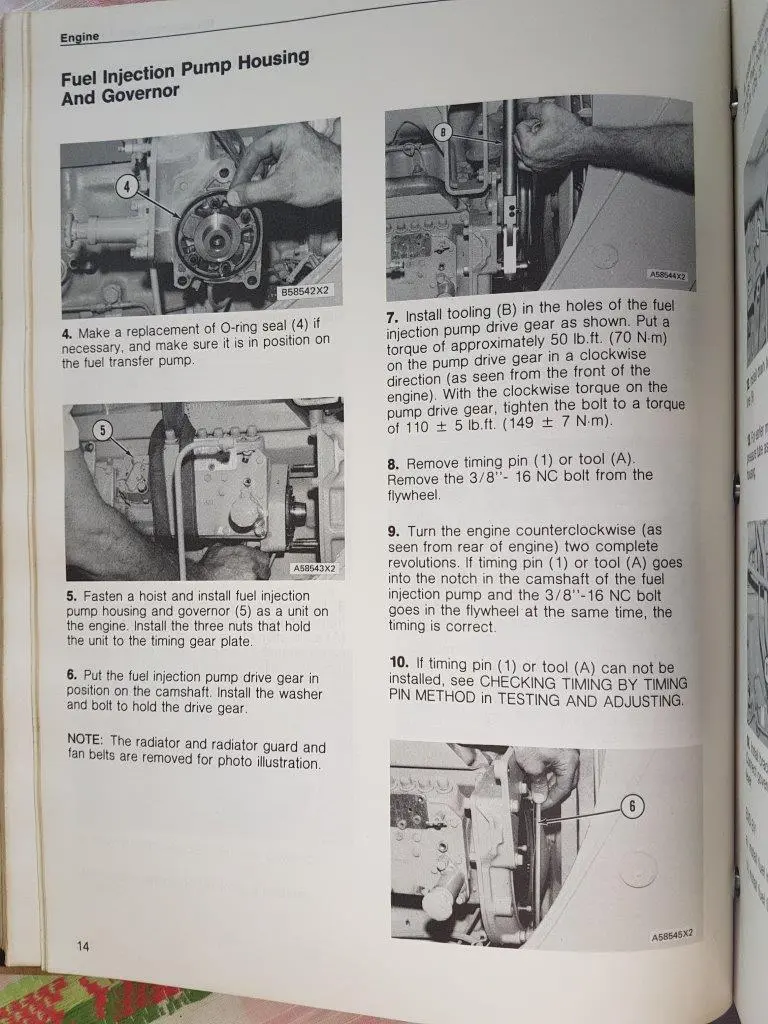

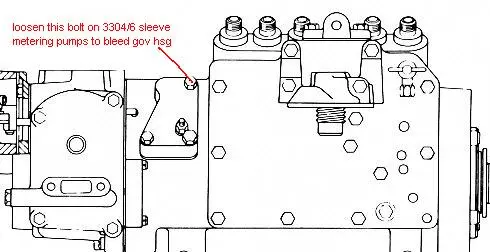

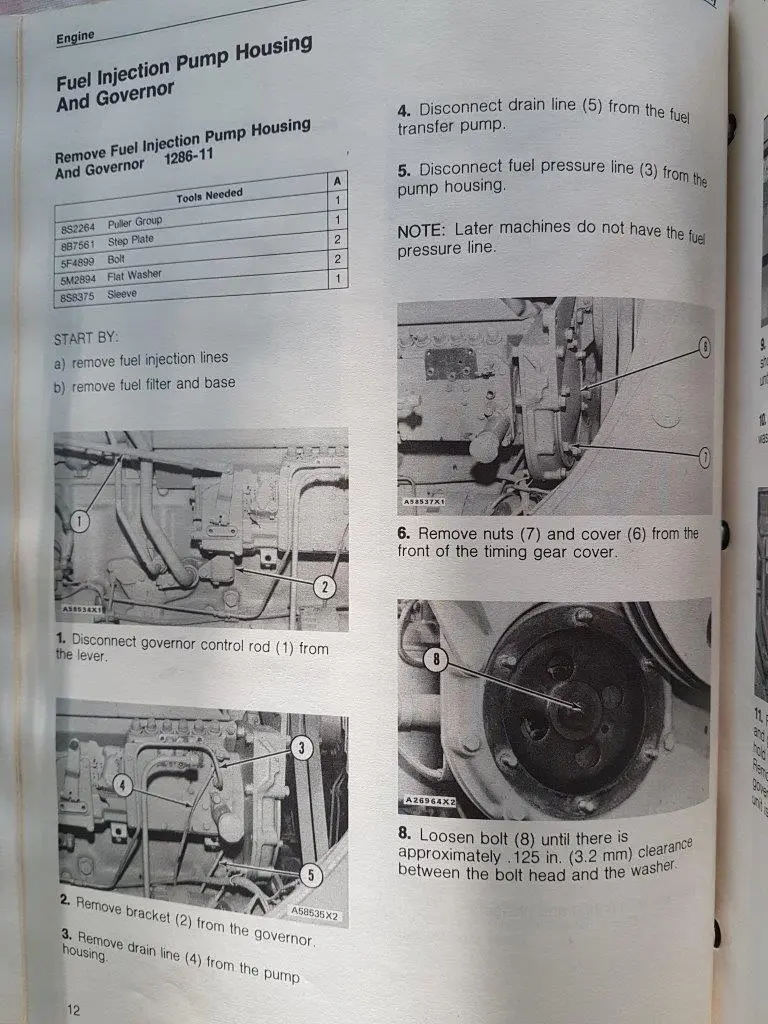

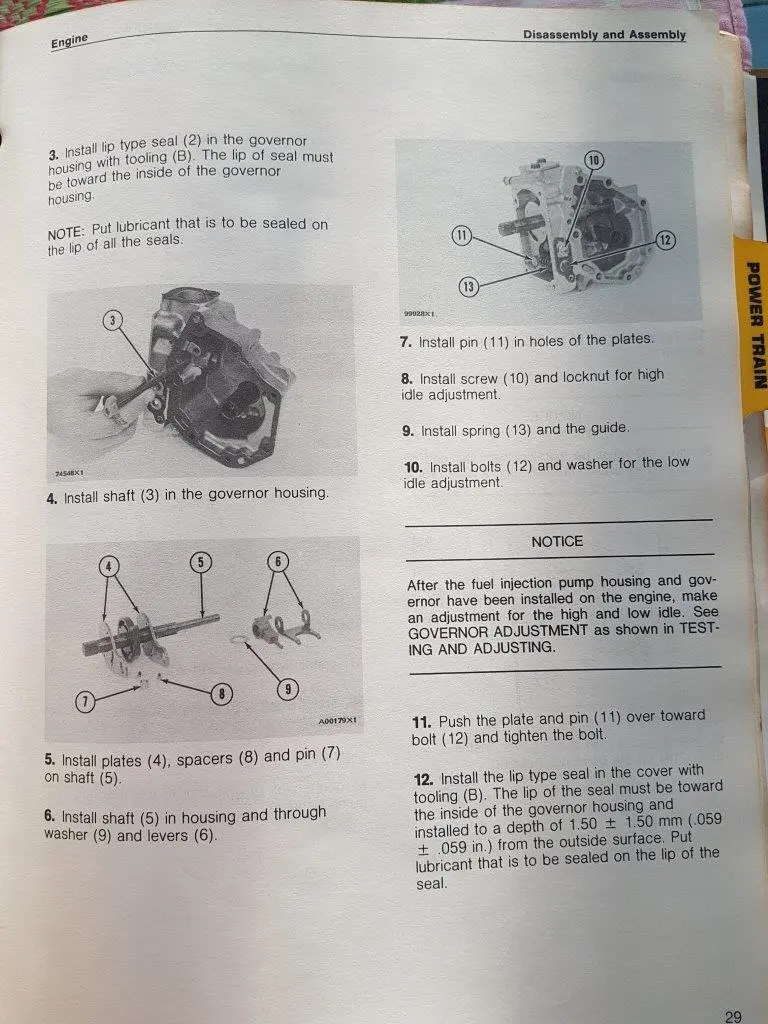

Pic 4,

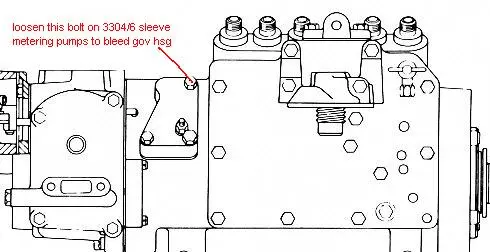

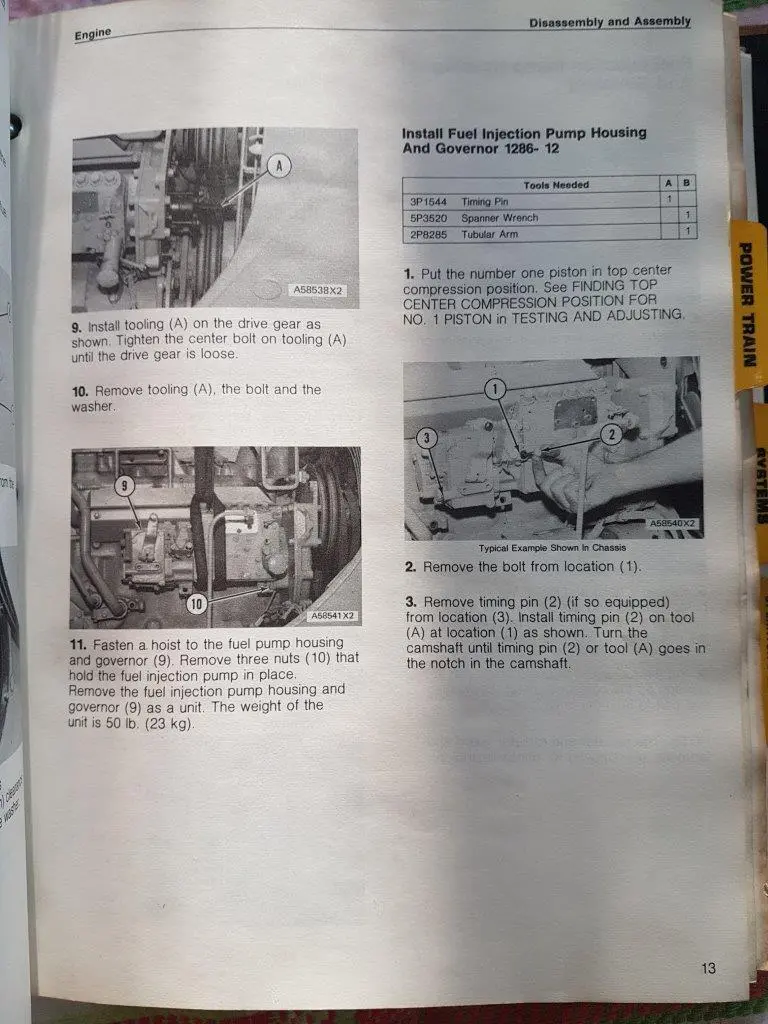

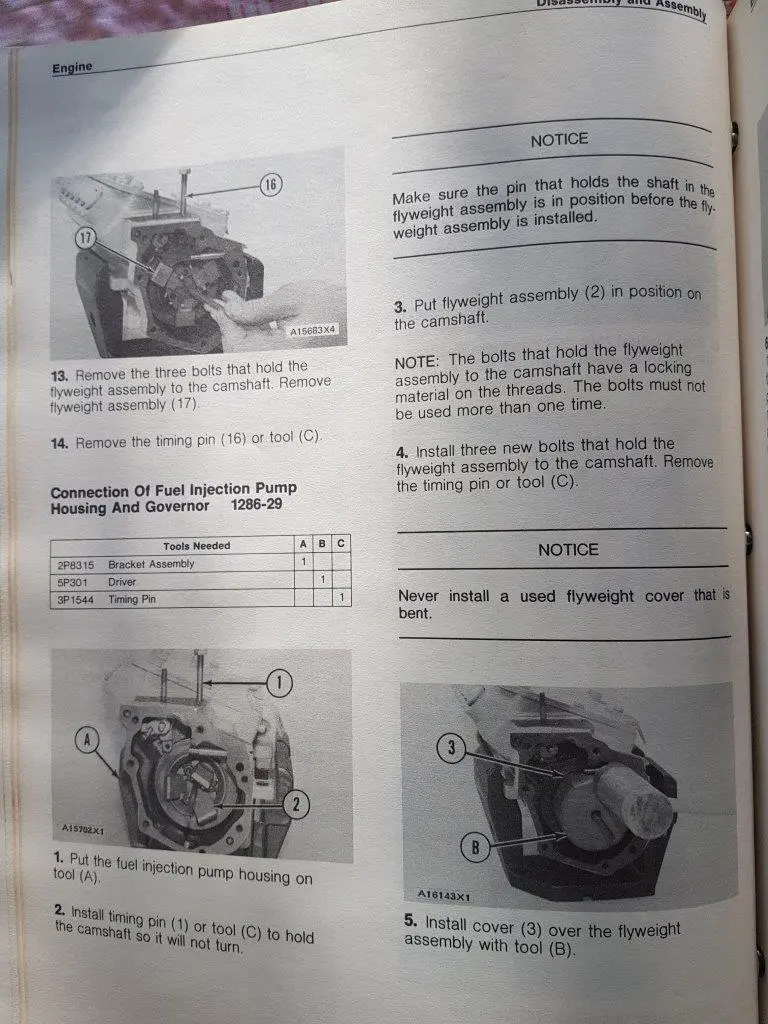

cannot recall but I think it is the end of the Fuel rack which has a lever and pin on that end from memory and as seen in the PDF which should assist you in sorting it out when you view the pictures over several pages. It looks odd because the levers act on the pin and so it does not seem to be connected to anything but it works when everything is aligned correctly.These are complicated but if anything is wrong ti usually does not assemble --do not force anything and go back and recheck until it slides together easily. One could say they are a bit smoke and mirrors type magic in operation.Also attached is how to bleed air from the Governor Housing or you will crank for ages to get the fuel level to rise in the main housing for the injection pumps to pick up--fuel sits at a low level in both housings and must be compressed by the fuel transfer pump pressure to raise the fuel level to run.Hope this helps.

Cheers,

Eddie B.

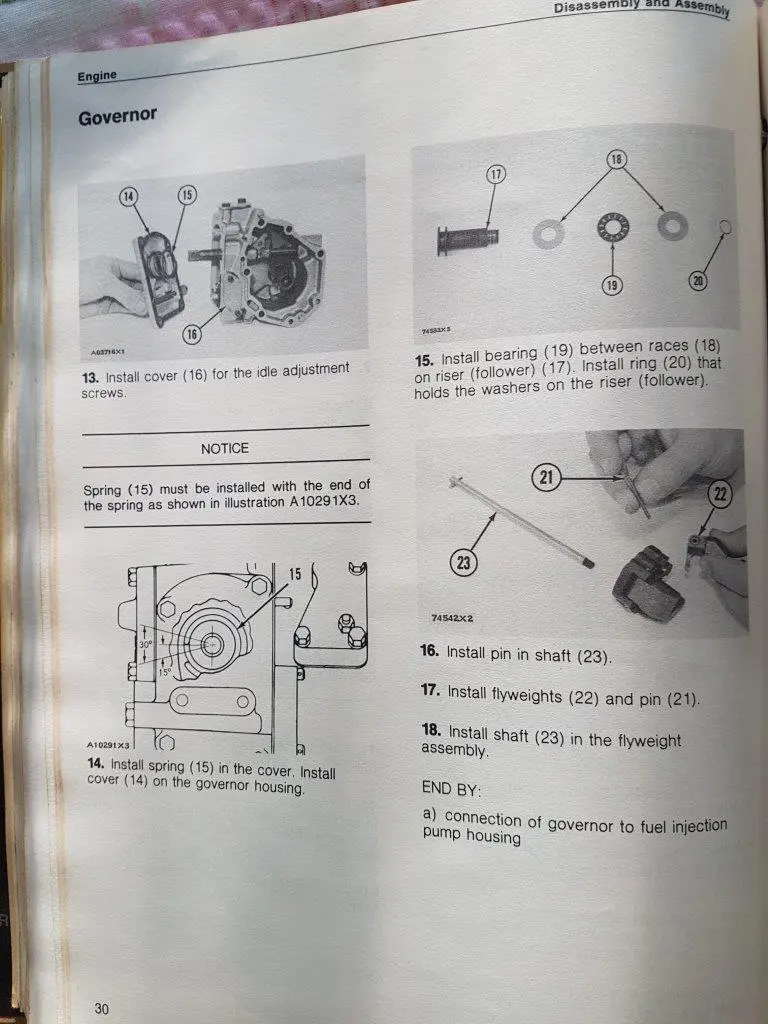

EDIT, looks like the PDF is too big to attach--I have tried copying pages from it so far without success--Sorry--this data should be in the Library here.

Have added some scans I saved from someone's post in the past alas one is too small and blurry to read.