"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

what is that 3rd pivot for?

have you connected every thing?

is something out of correct position check carefully that could be the issue.

when the main engine starts the opposite forces cause the latches to release. are they adjusted correctly if out of adjustment they wont work properly.

Hi,

remove the pipe plug from the clutch cover and you will find the pinion latches below the plug opening--you may need to turn the pony with its crank handle to align one of the latches to the opening so you can view the latch operation---once engaged the latches do not release until the diesel starts. They can be released by pushing down on the screw adjuster end of one latch as they are geared together.

If the latches are not staying forwards after attempting to latch onto the two flat bolt head that holds the pinion sleeve on the shaft you may have the latches aligned to the flats causing it to have nothing to latch to--the latches have to NOT align with the flats to work as designed.

If the unit does not go forwards far enough to latch it could be the lock washer for the two flat head bolt is too large a diameter or one of the locking legs is fouling the sleeve.

These links to Toby's tutorials may help explain clearer---all pony pinions of the gay were so similar that the D2,4 etc are basically the same operation.

https://www.youtube.com/watch?v=lKI3wTZU4AA&t=23s

https://www.youtube.com/watch?v=vo0m1XBqdBY

Only other things to check are that the engaging lever pad inside is not unduly worn or that the wear button on the end of the pinion gear is in place--if they are at fault you may not get enough travel to engage the latches.

Can you engage the latches by hand or does the pinion sleeve advance forwards or is it locked--if locked the very short bolts that hold to pinion gear to its sleeve may be too long and are locking the pinion from moving forwards to engage the latches.

Hope this helps if not keep asking--let us know how you went please.

Cheers,

Eddie B.

When I rebuilt the pinion sleeve assembly; I used a brand new pinion gear from Cat. I did as the videos explained to testing it. I experienced problem when pinion gear got behind the flywheel gear but was able to get a heavy wire to pull it back. I believe the new pinion gear is having a hard time aligning with the the flywheel ring gear.

Sorry but I am having trouble visualizing your issue.

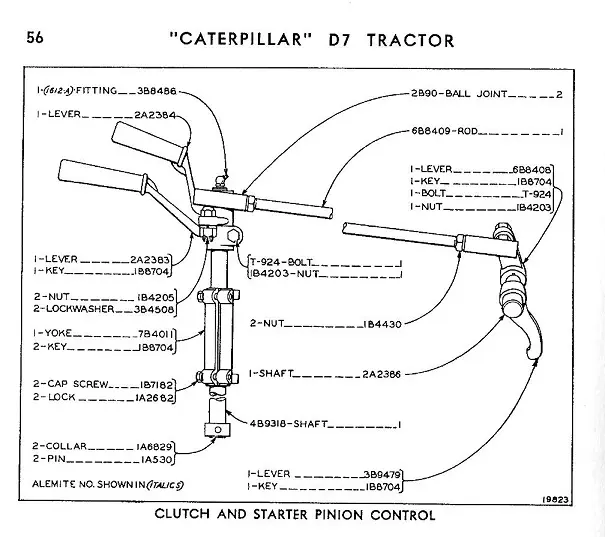

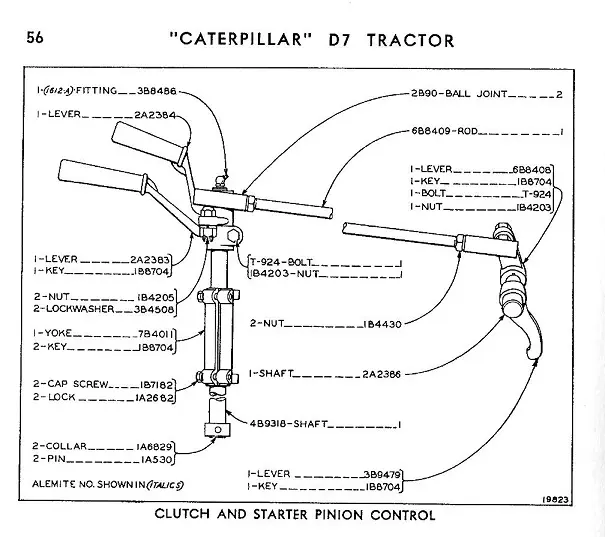

As a starting point this pinion engagement is done mechanically by the lever system that has nothing connected to it in your first picture above--these are not a centrifugally engaged pinion.

Scan below shows the controls.

Toby's RD6 Starting Sequence tutorial holds good for your D7.

https://www.youtube.com/watch?v=OiUL4UkERls

If this is missing your issue then keep supplying info until we get you past it.

In a pinch you may need to remove the Main clutch top cover and operate the pinion by hand as explained and get us some pictures of the issue if you can replicate it.

Cheers,

Eddie B.

I disconnected lever system because I was only getting 1" movement in the lever that contacts the rear of the pinion sleeve. When I started the pony engine, I could see the pinion sleeve spinning. I feel the new pinion gear is not engaging with the flywheel ring gear because it is brand new. I am positive it is the right pinion gear, before I installed the upper bell housing; I tested the pinion sleeve to make sure it was working correctly. The pinion gear slipped past the ring gear on the flywheel and it took me 1/2 hr using number 9 wire to get it back to the proper position. I will try prying on the sleeve with screwdriver and if that does not work; I will push start the old Cat and see if vibrations from old girl will free the pinion sleeve.

But any and all suggestions are greatly appreciated. John

I disconnected lever system because I was only getting 1" movement in the lever that contacts the rear of the pinion sleeve. When I started the pony engine, I could see the pinion sleeve spinning. I feel the new pinion gear is not engaging with the flywheel ring gear because it is brand new. I am positive it is the right pinion gear, before I installed the upper bell housing; I tested the pinion sleeve to make sure it was working correctly. The pinion gear slipped past the ring gear on the flywheel and it took me 1/2 hr using number 9 wire to get it back to the proper position. I will try prying on the sleeve with screwdriver and if that does not work; I will push start the old Cat and see if vibrations from old girl will free the pinion sleeve.

But any and all suggestions are greatly appreciated. John