Standard bearing journal on this crank is 2.625". These were turned down .030" on a prior rebuild and now measures at 2.585" . The rod journals showed no wear and probably 1 to 2 thousandths out of round.

The compressed wax was consistently closer to .003" than .002" and it was very uniform, all journals the same. It was placed on the rod end of the bearing, not the cap.

If your reading the plastigage on the low side of the rod journal with 0.001 to 0.002 out of round then your clearance is going to be to tight on the high side.

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality

i know it might sound silly are you reading the metric or imperial readings. plastiguage is available in both units. and have you read the right line in the spec chart. i use a ruler as a guide when i do that sort of stuff so i know im reading the right info.

its a easy mistake to make.

also a family friend was rebuilding a engine yrs ago he bought 7 sets of bearings before he got a set that was correct. the bearings when checked didnt match what was printed on the box it does happen that they are mislabeled and besides not every single bearing is checked before being packaged as they are mass produced.

be aware they may be marked in metric units too.

it doesnt hurt to check it can save you time and money.

-wondering how you know the rod journals are that much out of round? when they show no wear?

2 thousands is a lot...you might to touch those up to be safe..it would give you a bit more clearance too..

-what about the big end of the connecting rod? is it perfectly round? i don't know with diesels but with gasoline engines it is very common to have to resize the big end to make them round again (concentric) esp after the rods have many hours/miles on them and go thru torque cycles..

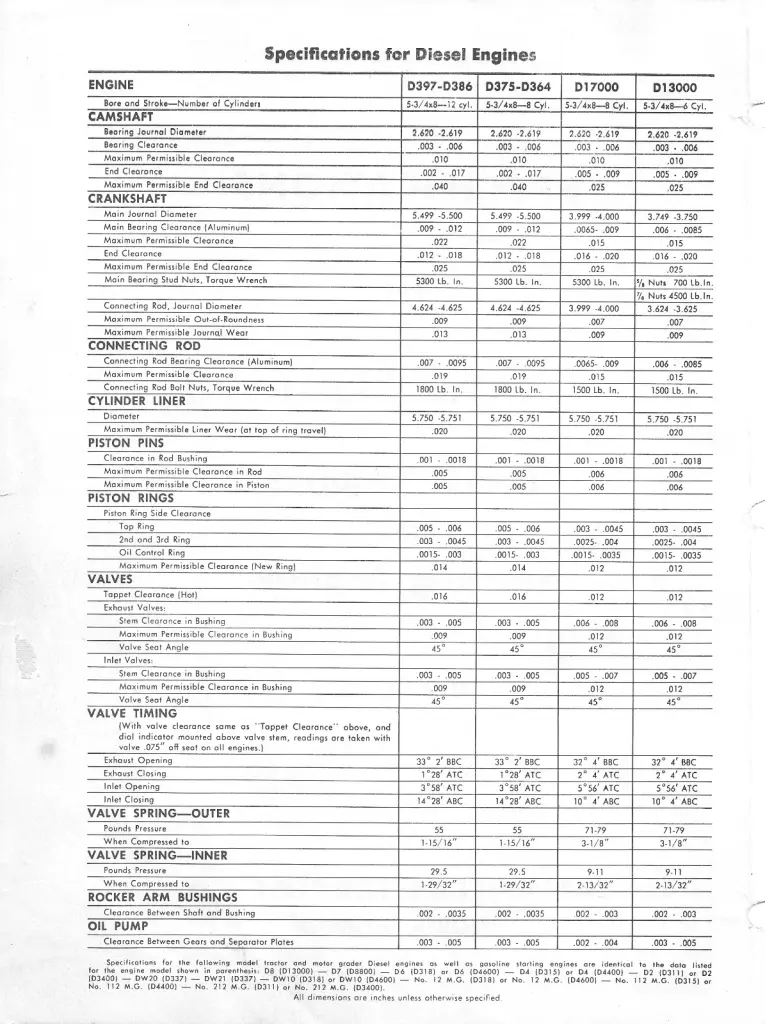

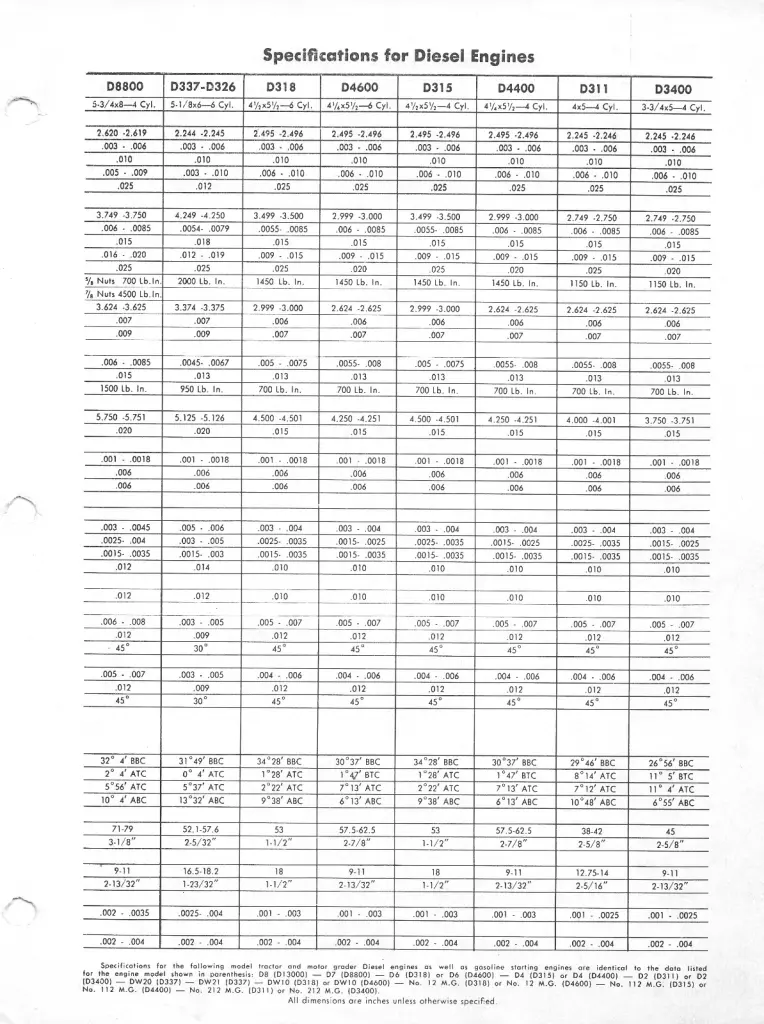

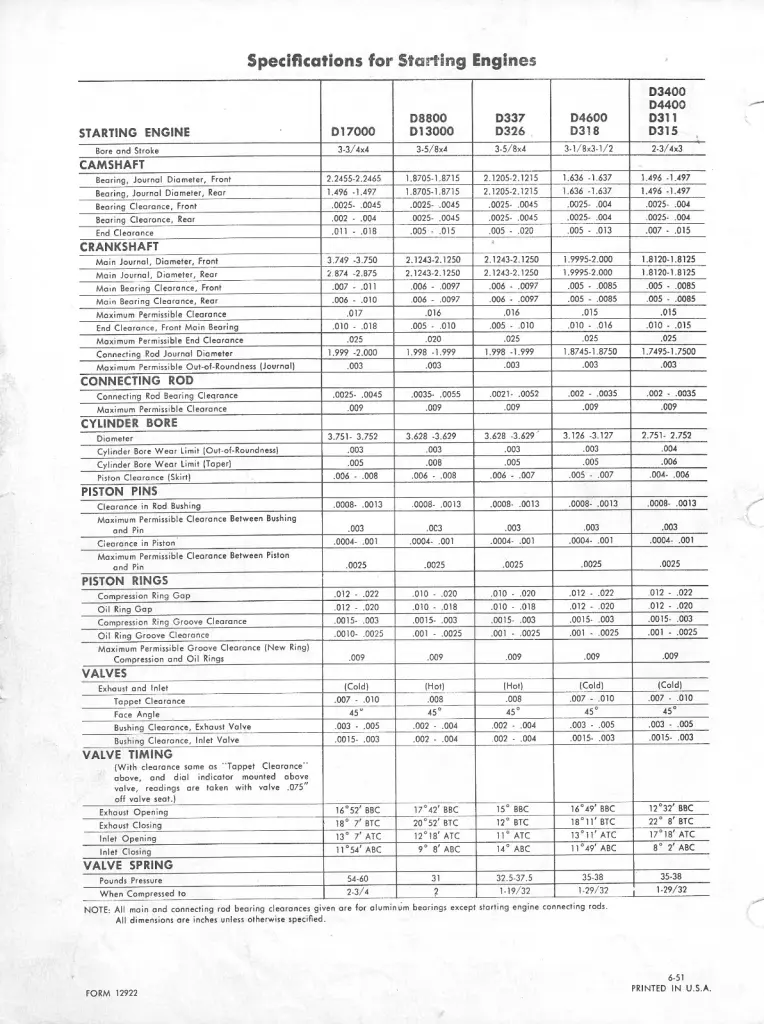

"it helps us immensely if you give the model and Serial Number of the unit you are working on as these specs can vary over model ranges of engines as bearing metals changed.

Grab these for future reference."

Eddie, sorry about that. This is for a D6, 4R1143, 1942. I got my specs from the Cat Service Manual Form 30419, and the specs match the sheets you sent me. Thanks for these, though. Much quicker to scan.

"If your reading the plastigage on the low side of the rod journal with 0.001 to 0.002 out of round then your clearance is going to be to tight on the high side."

I'm afraid of that being the case.

Kitty lover, I know the out-of-round specs from measuring it and the mechanic who polished the journals confirmed. They are well within spec, but i guess it's not accurate to say the journals show no wear.

In any event, before I pull the crankshaft back out, I'm first going to first put the used bearings back in and plastigauge in multiple positions and see what it looks like. I really, really don't want to remove the crank and haul it 2 hours away to Fresno (no local engine shop can handle this crankshaft.

This time I'll take pictures.