Reply to SJ:

CC, the earlier impeller was just metal to the seal but in little later years Cat wet to the ceramtic seal surface on the impeller where it rides against the seal.He will have to check and see which his has in it and usually if the impeller is all metal chances are it,s worn beyond using over again.I have rebuilt dozens of them over the years on various engines and the older ones were pretty much the same setup on the impeller and seal assem. back then.Sometimes the impeller can be smoothed up if it isn,t worn too much.It was a good improvement when they went to the impeller with the ceramic seal attached to it for a replacement.

SJ, I got to thinking and I can't remember is the seat is ceramic or polished metal (silicon carbide?). Either way, I know it's hard on them to sit for months sometimes and then start up. Ours that failed that way had shattered the carbon seal ring so it was really leaking fast!

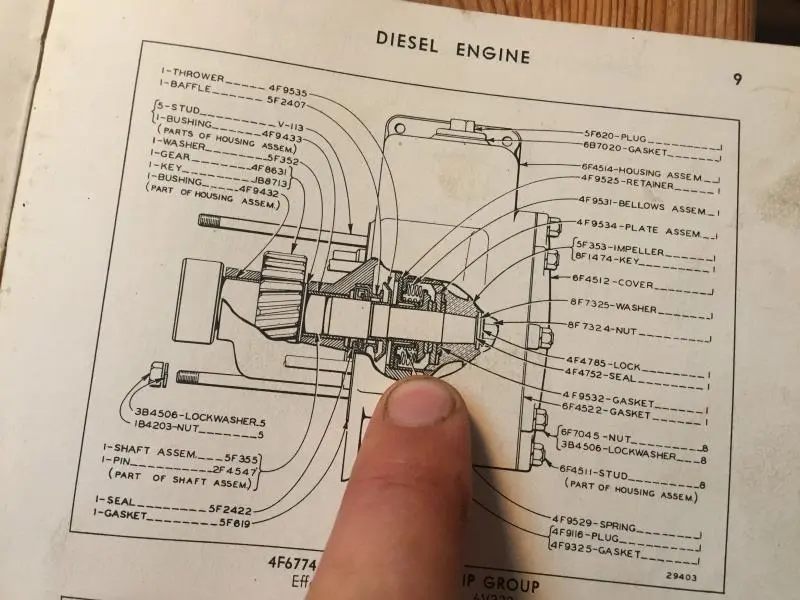

Might be possible to machine the impeller to take a seat if it's worn too bad. Just have to cut it back enough to take care of the thickness of the washer. Looking at the parts book, I don't see any separate seat, they show a

4F4769 seal assembly consisting of-

2H560 bellows assembly (does this include the carbon ring?)

5F9140 washer (seat or carbon ring?, can't tell from the parts book picture)

Impeller is 4F5995

D2-5J's, D6-9U's, D318 and D333 power units, 12E-99E grader, 922B & 944A wheel loaders, D330C generator set, DW20 water tanker and a bunch of Jersey cows to take care of in my spare time😄