Reply to Ray54:

Without major blow by or oil consumption I would say look at the fuel system. What RPM is the engine running. Back 40 years ago I put a kit in one really did nothing. Had old guy check it out it was not running up to 1600 so we speeded it up, over shot the mark and ran it about 1700 high idle. Made a different tractor out of it.

At first Cat had them at 1400, but turned them up to 1600 latter on. The 318 engine in the DW 10 scraper was turned up over 2000 if I am not confused again. They did have a different governor and other parts on the engine made for the scrapers. But proves the bottom end can stand more RPM than the setting used in the D6.

[quote="Ray54" post=224757]Without major blow by or oil consumption I would say look at the fuel system. What RPM is the engine running. Back 40 years ago I put a kit in one really did nothing. Had old guy check it out it was not running up to 1600 so we speeded it up, over shot the mark and ran it about 1700 high idle. Made a different tractor out of it.

At first Cat had them at 1400, but turned them up to 1600 latter on. The 318 engine in the DW 10 scraper was turned up over 2000 if I am not confused again. They did have a different governor and other parts on the engine made for the scrapers. But proves the bottom end can stand more RPM than the setting used in the D6.[/quote]

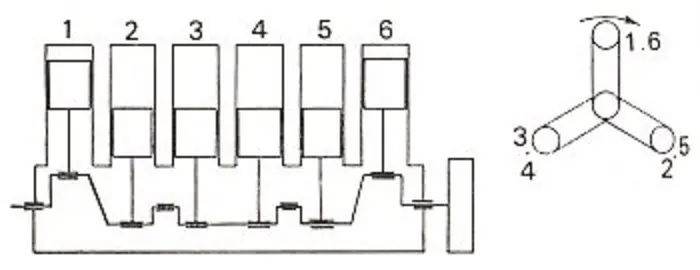

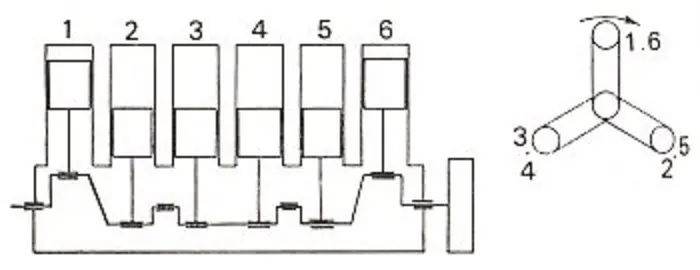

i just picked this dozer up, it was hard to pass up the deal imo.... therers a parts cat and a good cat all for 3k.... the good cat is really straight (serial number is 9U2564), undercarriage is all nearly brand new, has upgraded solid front idlers, has been upgraded to an oil clutch, hardnose with hydraulics, direct electric start, winch, etc. It also isnt beat up and all the guards and pans are there. It has a really bad miss and smokes terribly but i was aware of that going into the deal. Its only running on 3 out of 6 cylinders, the smoke totally disappears if i crack all 3 of the "bad" plunger lines and the engine rpm doesnt change a bit to crack those lines. But your also right we havnt totally ruled out fuel problems but figured since my father has the equipment needed to do a balance test id start with that and see what it shows.

Can anyone give me the proper specs to set the valves on the engine ? I tried to google it but everywhere i looked there is a different answer it seems.

Is it worth it to set the governor to the higher rpm ? didnt the later 9u models have a bit higher horse output, im assuming this was just different settings/adjustments made to the fuel system, is it worth while to turn it up to those settings (after the issues are taken care of, of course)

thanks for the info !