Cats Forever

Cat manuals are known for over simplifying an operation. Maybe it is the white lab coats that help them.

I am not sure about the 5J but I have a D47U (1950) and the pinion, clutch etc will come out if you have the pony raised high enough to clear the pinion gear.They say two inches but I lay 2x4's on edge to raise the pony about 3-1/2 inches. You have to remove the back governor case cover and the cover on the front of the clutch brake. Getting the whole mess out of the housing can be a chore as they get rusted in and need a lot of Kroil and gentle tapping to get them loose. Don't beat them too hard because they can break. As for the 5J I have never worked on one so don't know if there is any difference. It is a big help if the pinion can be latched to shorten it up. It is a tight fit but it will come out on the 7U. .

Good luck.

I just removed mine from a D2 and the first challenge was overcoming the force of the large o-ring in the rear of the pinion. It's a pretty tight seal and not easy to grab to pull or pry to break the seal. I was careful not to put too much force around the area where the bolt holes are, in fear of breaking the corners off. After I got that free, there wasn't much room between the governor and the pinion, I had to give it a little pry to get it to clear. It took me a while but I finally got it.

The 3/5J comes out with no additional disassembly from my recollection. The 4/5U series though required the governor and pinion covers both to be removed. But the tightness issue with the o-ring is the same on both series. I did get an updated o-ring number where the cross-section is just a little thinner and so the fit was a bit easier.

Thank you everyone for the input. Am I missing something? Seems like the whole governor assembly needs to come off. I was hoping things would be minimal. I still have quite a long way to go for the nose of the drive to clear.

I took the whole governor off on my D4 2T, made it straightfroward. As Neil said overcoming the large o ring takes a some force. I actually used a little heat to soften the o ring which helped a lot.

Is the pinion latched to make it as short as possible?

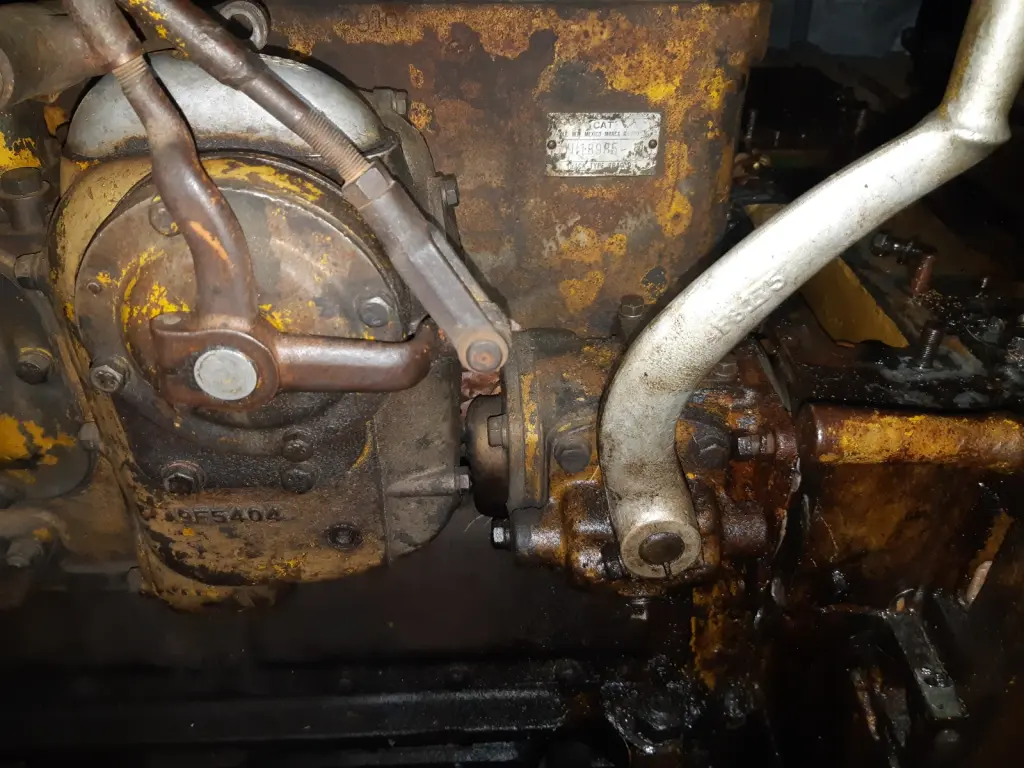

This is where I pried from the back. The top of the pinion and the bottom of the governor were making contact, so I took a pry bar and gave it a little help. Didn't take much. Like Neil mentioned, I had the pinion engaged.

Thanks for the pointers everyone. I'm a little unnerved at the thought of removing the governor assembly. I'm doing this right out in the open. In the muck in the corner of our yard. It's what I've got! I was hoping to have it sorted before we get a dump of snow.

Today, I drained the coolant out of the 5T, removed the dash panel, linkages and unbolted the pony in preparation for lifting it. The pony exhaust bolts were pretty seized on the main eng intake side. I've got them covered in a rag soaked with liquid wrench so hopefully after a couple days it will be more easily persuaded. I don't have a oxy acetylene setup so taking the slow road. That was enough for me today. I don't work on my tractors unless I feel like it. I only do this for enjoyment 😁

I believe the pinion is latched on my 7U but I will double check. Also, it the spirit of saving money I seldom go to the Cat dealer but I'm thinking I will for the large o ring for the drive to the housing. Is cork gasket a valid material for between the pony block and the bellhousing? Its 1/16". Or should I only use paper type? I have the cork in a large chunk so that is why I ask.

Much thanks!