Cats Forever

It looks to me that it is just your mounting bracket that has been butchered.

[attachment=60601]20200925_100258.jpg[/attachment] [attachment=60602]20200925_100532.jpg[/attachment]

Likely someone left the transport pin in place and worked the hydraulic system until they blew it out of the mounting surface.

Why do I think so? Because the one Glen (R.I.P.) gifted me was that way!

I’m taking mine out again for repairs; whoever re-welded the flange/plate for the cylinder did not have it re-bored, hence a slight ridge can be felt internally.

CAT had all of the parts I needed originally, but this time I’m going to have my local shop bore the tube and change the piston and seals to high pressure.

Please share your 40 progress.

I’m working on one of mine as well.

Best wishes, JM

[quote="juiceman" post=222388]

Please share your 40 progress.

I’m working on one of mine as well.

Best wishes, JM[/quote]

"I'm working on ONE of mine" Have you become a hoarder of Cat 40 scrapers????????????

Or just that you have several scrapers of different sizes for different tractors and jobs.

Just being a smart a$$ ..........................................An if I ever get to a project I have been thinking about I know who to beg for a scraper.

Like JM plans to do, I also had a new piston made to with modern seals. Have done the same on D4 6/7U's and LaPlant scrapers.

Cats Forever

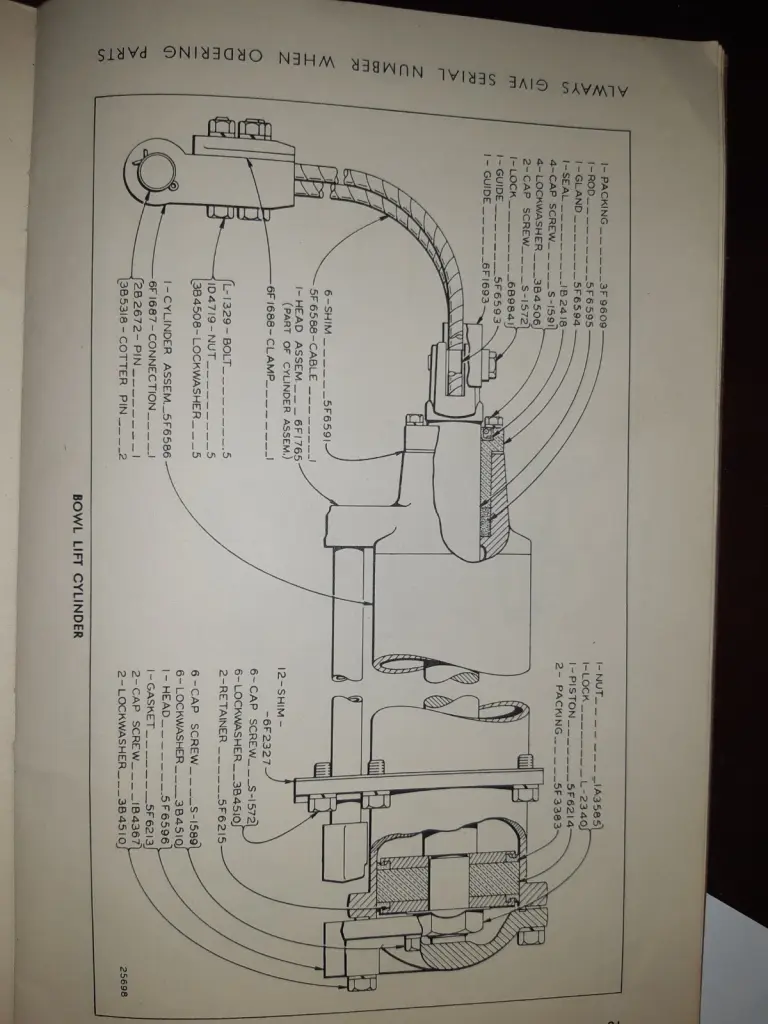

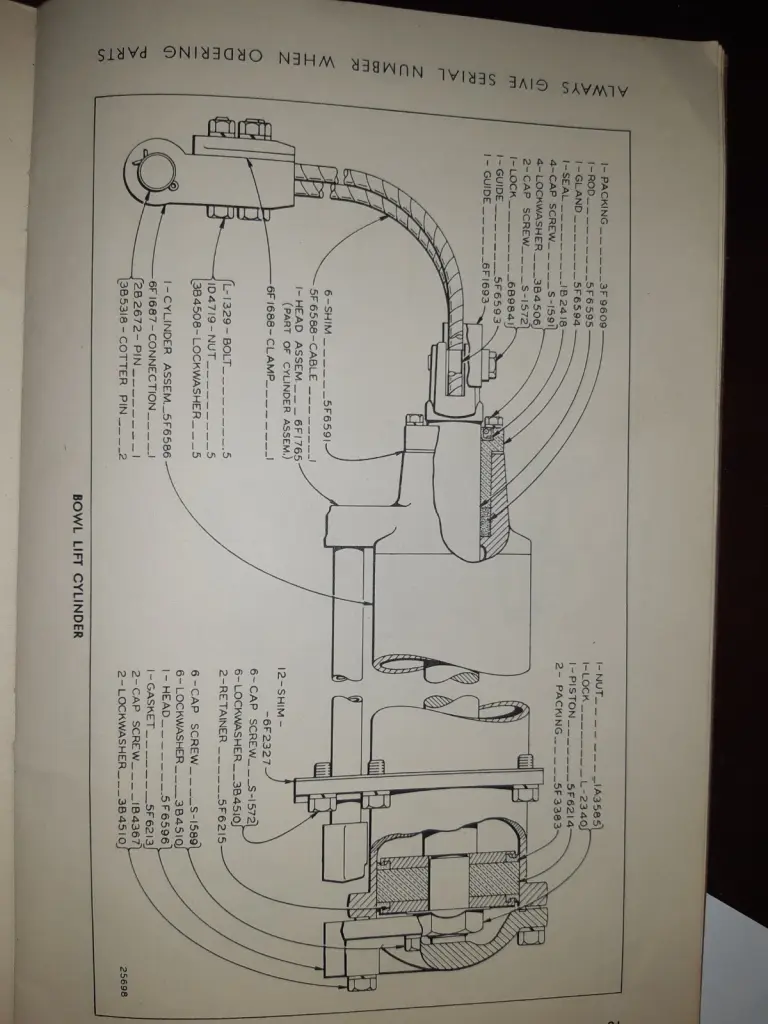

Thanks for the comments guys. I ordered a Serviceman's Reference like OM mentioned but can't seem to find a parts book. I have the operators manual but it doesn't show much.

I'm hoping I can get a drawing from Cat for the flange as the Parts Diagram by Glum shows the Cylinder assembly PN. We have a good weld shop locally that I think can cut the flange off, weld on a new one and turn the flange on a lathe to make it true perpendicular to the cl of the bore. Then I will have to send it off to Salina KS to get the hydraulics and bore redone and a new piston. Might find more surprises when I get into it but it should not be too bad.

As a note I made a pressure regulator to use to limit the pressure to 1100 PSI so if I pull it behind a Green Machine I won't damage anything more. (Actually the pressure is adjustable)

Thanks again.

Cats Forever

Might consider a hydraulic bowl conversion...