D330c pump was timed with a fixture that slips over some studs on the front cover over the pump drive gear. I believe the gear has a taper fit to end of the shaft without a key but I didn’t do it, just helped a local CAT mechanic reinstall the pump after a rebuild at the local dealership pump shop. Unfortunately the pump was never the problem as we discovered later the engine had ingested a mud dauber nest that broke up in the air intake. We found the remains of it and the small opening that had allowed the wasp to get in there and build it.

Sorry I am not more help

Hi Team,link below will get you all i have on this.

http://www.acmoc.org/bb/showthread.php?32258-D330-injector-pump-settings/page3&highlight=d330+rack+tooling

Cheers,

Eddie B.

Thanks ccjersey

Thanks Eddie

Is the rack setting tool spacer the same? It has a different part number.

Regards

Phil

Hi Phil,

sorry I believe it was OM who said the old 8M0530 Rack setting tooling---micrometer--has been replaced by a 7S7113--I stand to be corrected as I do not recall any knowledge of this but things change--I think our micrometer had some grinding done to the loose collar to allow it to fit in some tight space applications--other than that I am in the dark too.

Cheers,

Eddie B.

Is this what your looking for???

Hello OM

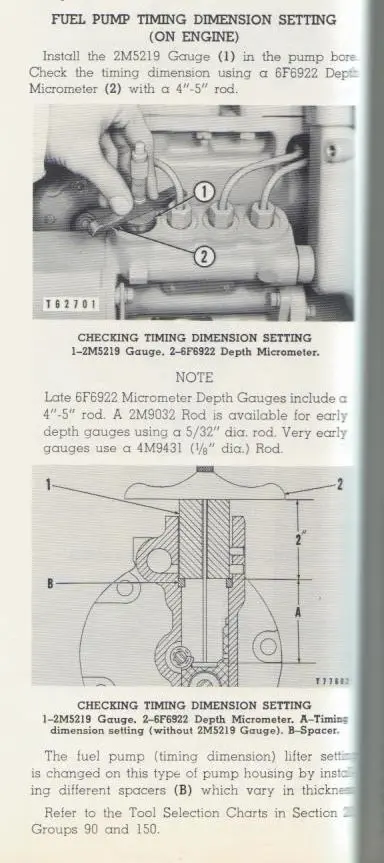

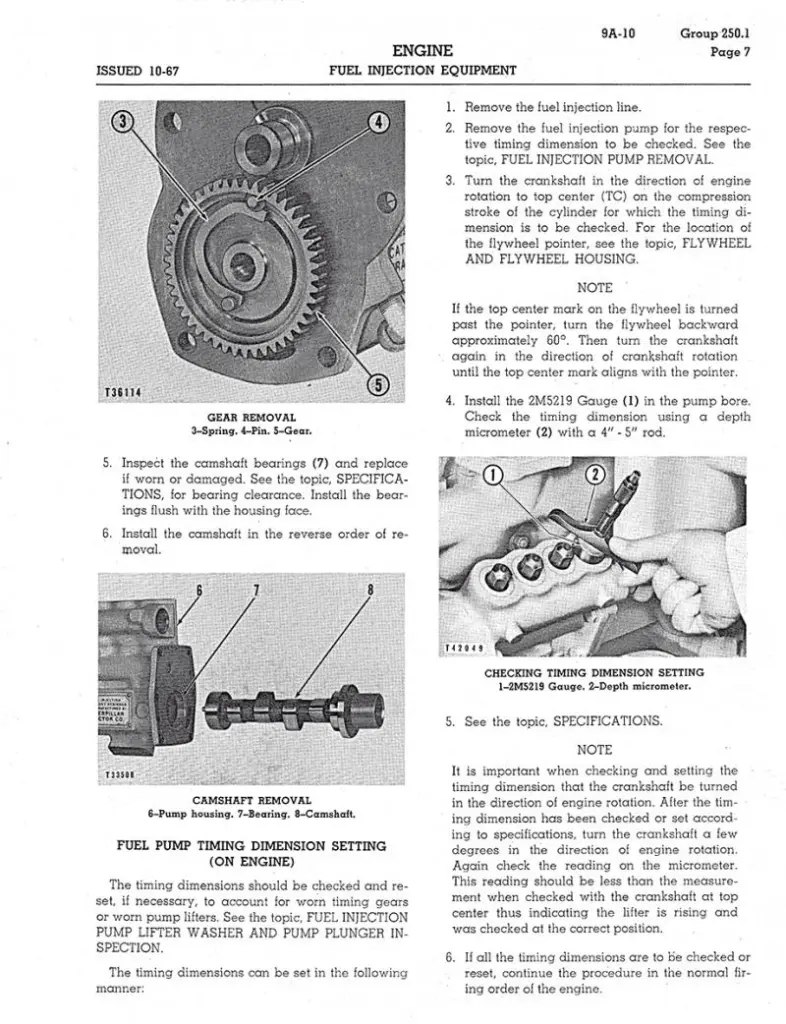

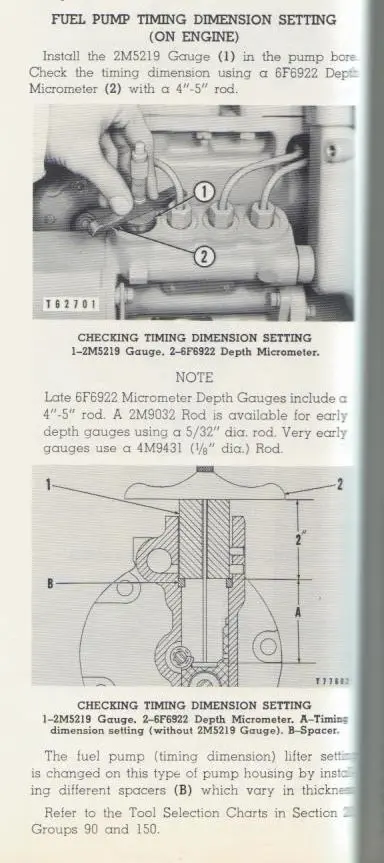

No sorry but thanks anyway. I am not trying to set the rack position. I have already done that. The procedure in the book for checking the timing is shown on the page below.

[attachment=60210]Manual 250.jpg[/attachment]

Hi Phil, the instructions you posted seem straightforward. I'm wondering if the "all four" instruction just means check the timing on all four cylinders individually i.e. go through that process described one cylinder after another, but yes, seems like a superfluous instruction. Maybe they're concerned that the wrong pump camshaft is in there, or something?

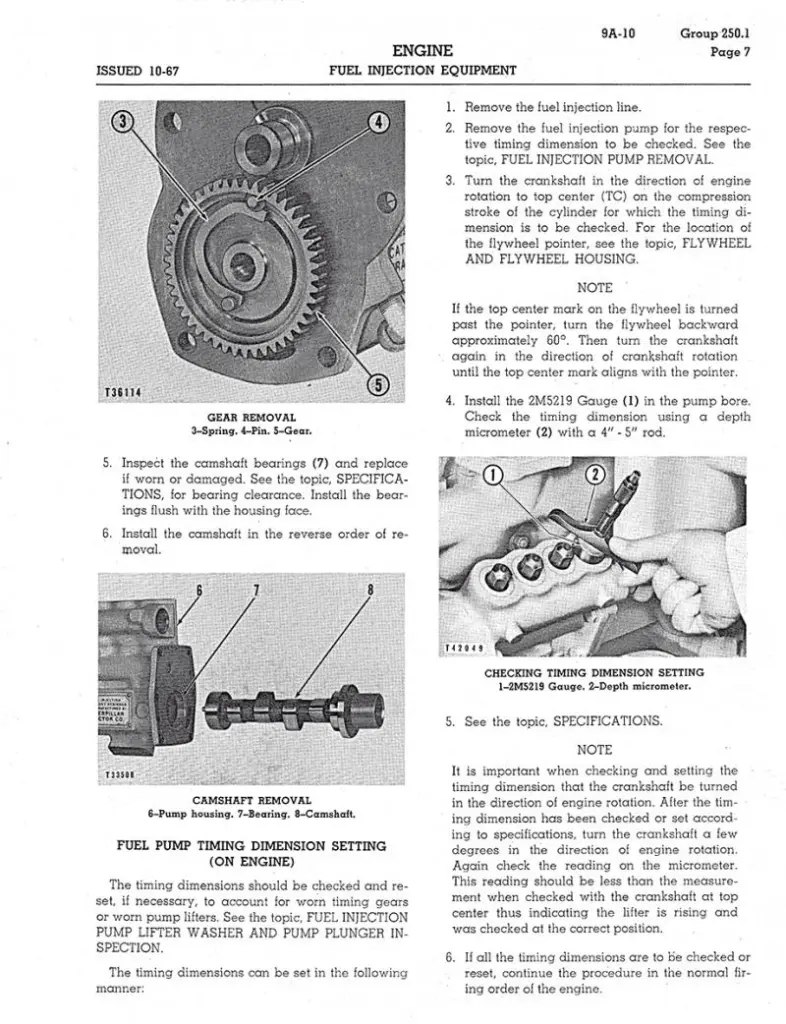

Individual pumps are timed by changing the spacer thickness. Can be checked with mechanical indicating tooling, dial indicator with gauge and plunger or gauge and depth micrometer. The usual gauge is a 2" high plug reference set into the housing to rest on the spacer/seat.

The current plug gauge for depth micrometer use is a 8S7167, available aftermarket at $12.99.

https://aftermarket.supply/caterpillar/8s7167.html

Hi Team,

just to reinforce what OM has added above I add this scan as taken from a Tool Guide Book.

Now if you are looking to check the pump to engine injection timing on the engine you will need to find the Injection timing BTDC dimension from the spec. section of your Service Manual and follow a Spill Timing procedure to check it.

I will do some searching and see what I have to add if anything.

You could easily use the lifter setting on engine measurements and double check No1 pump lifter setting at least to check actual on engine pump timing.

Remember doing on engine lifter settings on a 933 engine that was hard to start when I was an Apprentice--first one I ever did--they gave me the book and said here you are lad--check this--never seen one before--got it done with success.

Cheers,

Eddie B.