Reply to Deas Plant.:

Hi, crbeardon.

If you have pumped the priming pump up until it was hard to impossible to pump any more, that is about all you can ask of it unless you open a bleed screw. If your 3306 is like the one we have have here in a 966C loader, there oughta be a bleed screw with a T-shaped handle just above the priming pump. Open that and continue pumping until you have clean fuel coming through that. There may be a drain tube attached to this bleed screw which will direct the bled fuel and air down toward the bottom of the engine. If so, you will need to observe this while pumping.

Then loosen 2 or 3 nuts on the injector lines at the injector ends and turn the engine over with the starter to allow the system to purge the air from those lines. You may need to have somebody on the starter switch while you observe those loosened connections to check for clean fuel with no air and then tighten the nuts.

At this point, the beast should show signs of trying to 'light up'.

I may have missed another bleed screw but, if I have, somebody will likely chime and tell us.

Just my 0.02.

Hi,

to give correct data we need Serial Numbers and a pic or good description of the Injection Pump Fitted as there are at least two possibilities--Scroll type Pump and Sleeve Metering Pump.

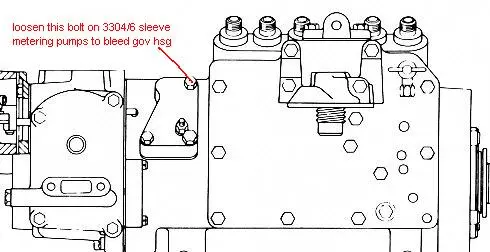

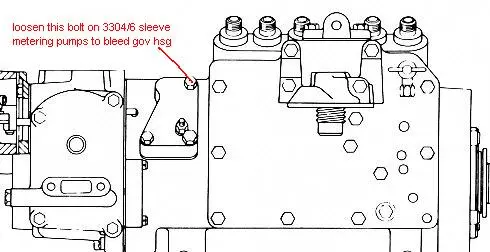

If Sleeve Metering then the scan below may help.

Explanation in post #8 on this link on why and how to bleed a Sleeve Metering Inj. Pump who's housings are full of fuel and now air due to being run out of fuel.

Sleeve metering In-line Injection Pump Air Bleed Point

The scan below shows where to bleed air from the Governor Housing after re-fitting the unit.

This fact is not in any Cat Manuals.

[u]The bleed tap on top of the main housing near the big side plate gets the air out of the main body of the unit BUT, some air remains trapped in the Gov. Hsg. and so needs to be bled also-- if this is not done you have to crank the engine until fuel can compress the trapped air, now in the main Hsg. again, back into the Gov. Hsg., which levels out into both areas when the engine is stopped, up to a level high enough for the Inj. Pump plungers to pick up fuel and so start the engine.

This issue is repeated each time the unit is started until said air is bled out.[/u]

Attached Thumbnails Attached Thumbnails

Click image for larger version. Name: 3304 6 FP.jpg Views: 19 Size: 27.8 KB ID: 87269

Cheers,

Eddie B.