Hi,

I seem to recall that the pivot shaft is held firmly to the transmission case by one of the two 4 bolt caps that has a dowel in it for this purpose. In that case there should be no movement or the shaft will fret and wear itself and the case etc.

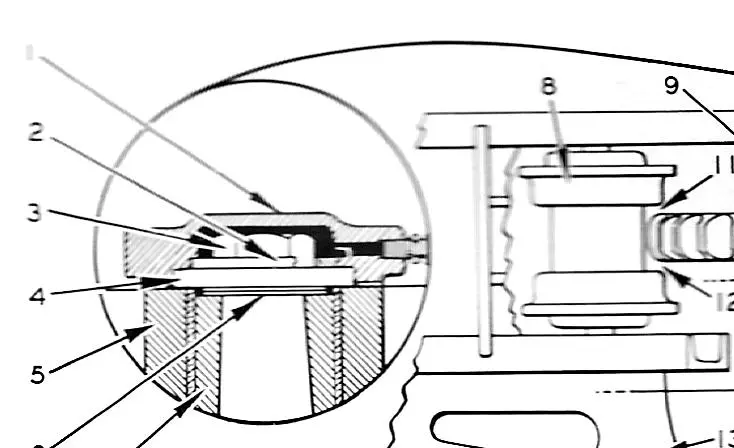

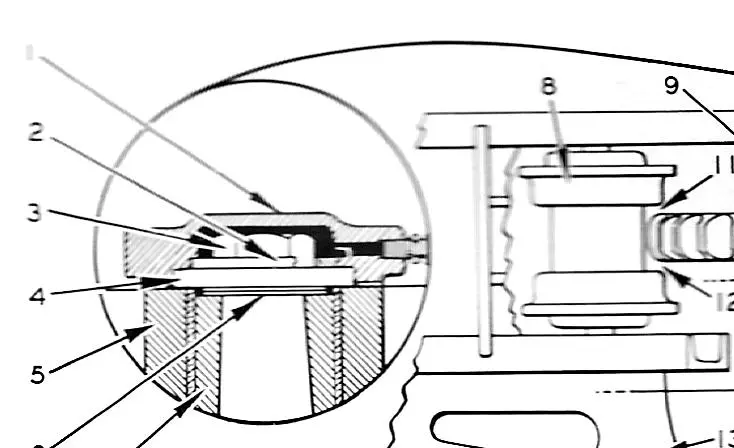

If perchance you are actually referring to the end float of the track frames upon the pivot shaft, this is set by the thickness of the thrust washer bolted to the end of the pivot shaft and the counter bore depth in the shaft end cap--the gasket thickness would play a part in this clearance too, but, if all genuine parts were used then the unspecified factory designed clearance would result.

I guess you then could use a thinner gasket to achieve an acceptable end clearance or a thicker thrust washer.

The shims under the pivot shaft end washer are used to achieve correct track frame rear roller to sprocket centralized alignment.

Cheers,

Eddie B.

EDB, thanks for the reply. i am actually doing by R2/22 thought it would be close. Apparently different construction.

Any ideas? .03 to .090? or just easy movement with no slop? I realize that this bearing not actually move a lot in service.

when i did my D2 undercarriage I had over 1 1/2 inches side play at the front idlers---this was from track frame twisting due to worn bushings on the pivot shaft

new bushings brought it down to about 1/2 inch

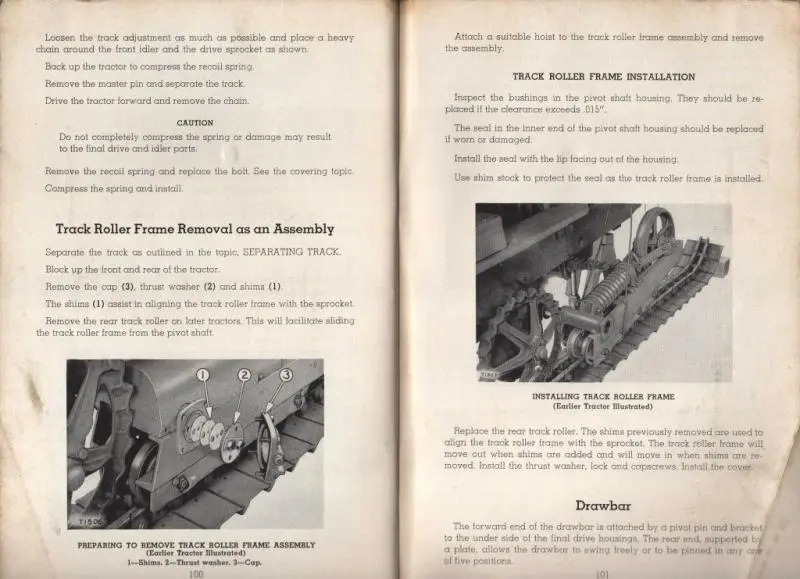

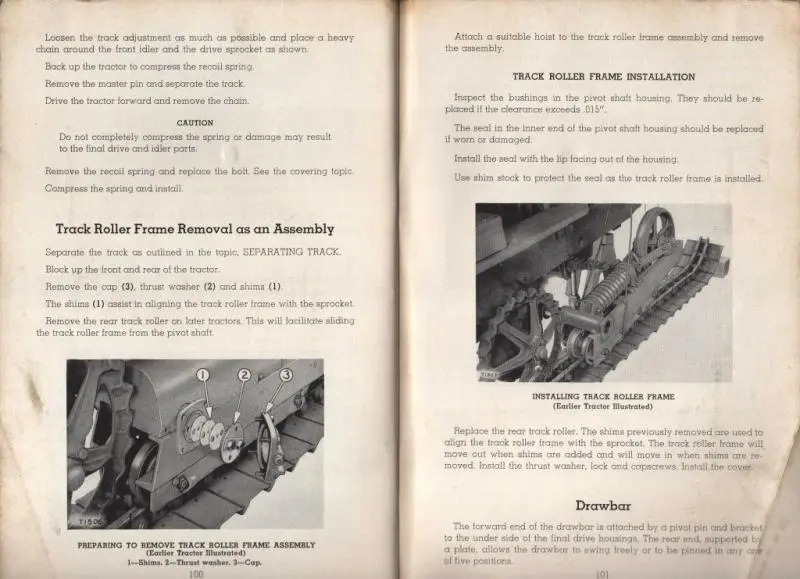

From the D2 Servicemen's Reference Book.

Thanks Josh, I shimmed my R2 pivot shaft so there was no side to side movement felt by HAND. I tend to overthink things sometimes. The track frames only pivot a few inches and so extremely slow moving. The objective is so they move and have no excess play. Greased well and they move nicely.

Hi,

the shims, as I described, adjust the position of the sprocket centre line to the rear roller centre line, so as the track links do not rub on one side of the sprocket teeth as well as causing the track links to run against one side of a roller flange from being off centre. Around 0.030"--0.040" end play should be acceptable.

The 2 Tons I had, used shims inside and outside of the track frame pivot bearing housing ends to centralize the T/Frame.

Now knowing we are talking about a 22 I can see in my Parts Book that they appear to be a similar set up.

Not sure if Bruceoz's 22 pages have this data or not.

Scan below is from a D7, but it illustrates what I am trying to convey about centering to the rear roller and sprocket centre lines.

Cheers,

Eddie B.

This is the entire assembly on my saw horses. All measurements were taken from the centerline and from the spacing of the pivot shaft brackets.

Thanks

[attachment=58390]cat r2 roller 005.jpg[/attachment]