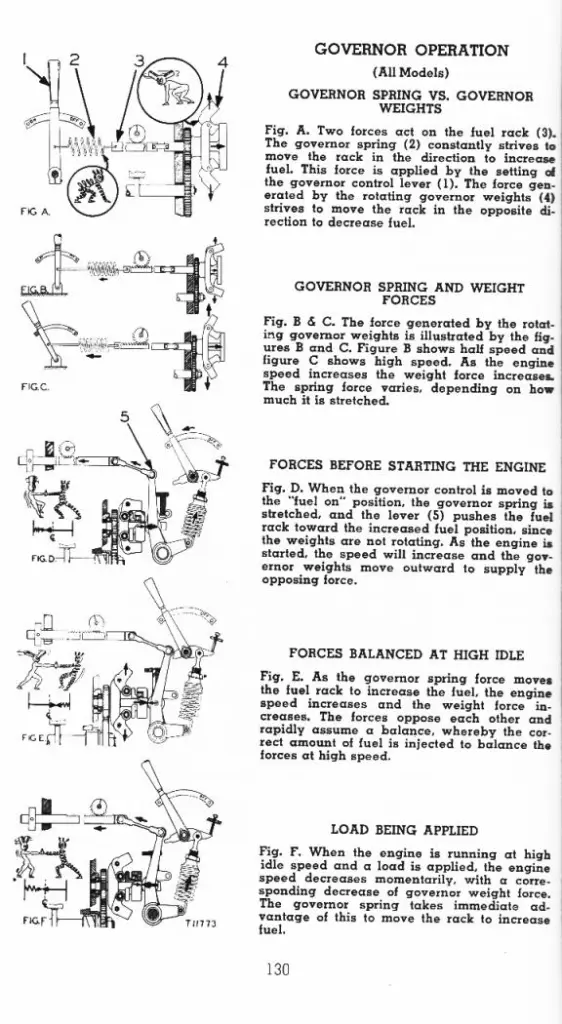

Cover on the end of the governor housing is easily removable to allow you to look inside and make sure everything is connected and flyweights are free to swing, pivots are not frozen up etc.

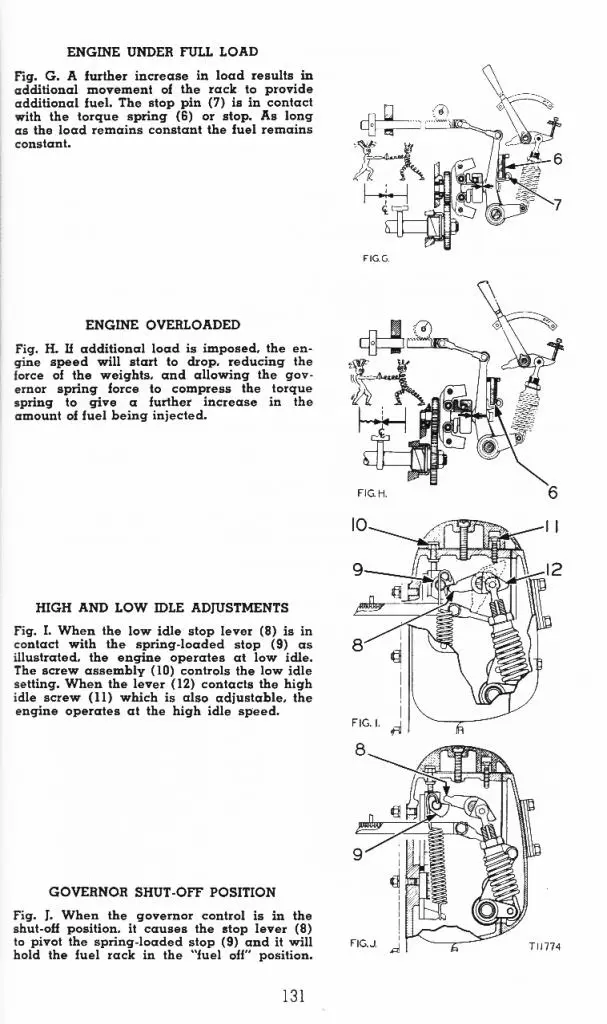

If you need more access, the side of the housing comes off after removing the throttle linkage, the crank and the detent mechanism. There really isn’t any adjustment other than the high idle and low idle rpm stops located under a curved top cover on the top of the housing, these are stops, limiting how far the different levers in the governor can move.

Since the rack is freely moveable, if you can’t see anything wrong inside the governor housing I would button it back up, refill the injection pump housing with oil and then I would attempt to regulate it by hand and get the engine to run

If the engine runs away, remember that you can pull the decompression lever to slow it down or stop it.

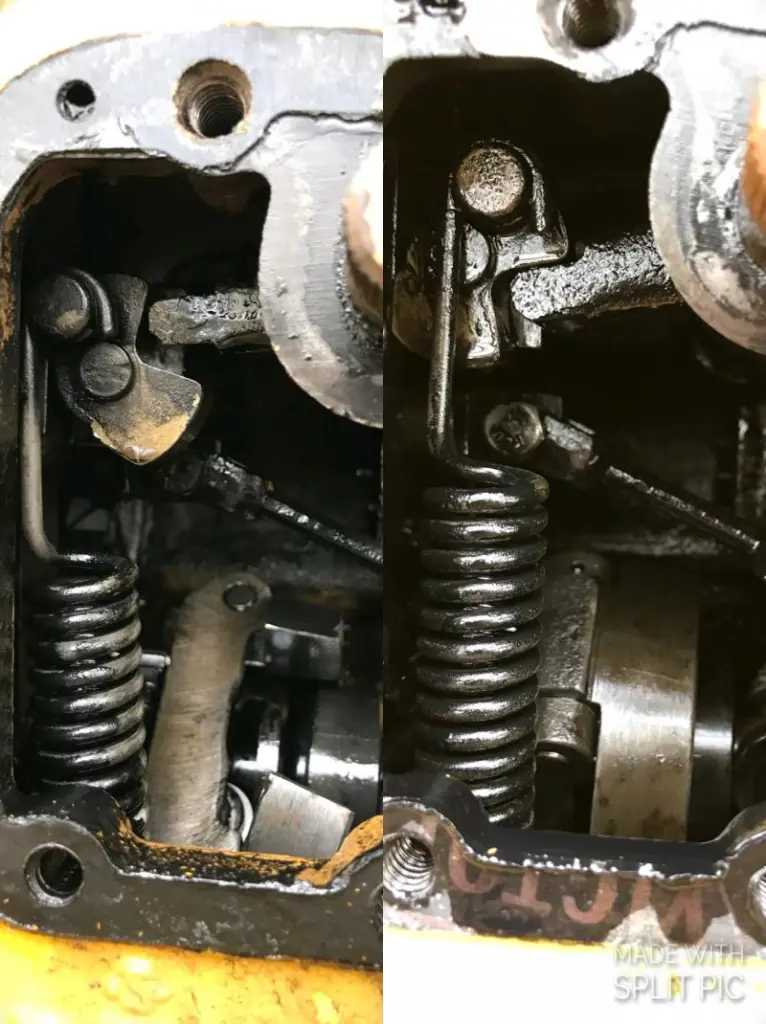

I would pull the cover off the side of the pump and see if the plungers are stuck up. It sounds like when you move the rack you are getting them to move some. Turn it over with the cover off and use some loose juice on them. You can gently help them back down with a small screwdriver. Also a great time to change oil in the pump.

If the rack slides back and forth turning the pump elements, the elements wont be stuck and will be free to move up and down.

[attachment=56511]IMG_1013.jpg[/attachment][attachment=56510]RFAN7374.jpg[/attachment][attachment=56512]IMG_1014.jpg[/attachment]

[video]https://youtu.be/T6s05RPaMB8[/video]

ok so I got impatient last night and bought a service manual. wasn't bad for 40$ on ebay. then woke up today and started looking at the grader again and just couldn't figure out what could be causing this problem. so of course having 2 other graders I took the running one apart and found a couple things noticeably different emediatley. heres some picures I I took so you can see the difference. the picture with the 2 pumps side by side shows the good running pump on the right. looks like a cam type spring piece cammed over. used a screwdriver and cammed that piece back to match the good pump. then matched the high and low screws on the top of the pump to match. started the pony and wouldn't you know it!!!! It STARTED!!!!! Holy Cow!! sorry I was so excited. was really nice to see it run. smooth and good oil pressure. and thank god all the plungers move. Ill upload a video for you!! Thanks for all suggestions