D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

we used to use a metal 5 gal bucket and fill 1/2 full of propane to shrink parts, if you choose to use propane then use it outside only. also you can use dry ice and 90pc alcohol to freeze parts. for heat you need a rosebud and oxy acetylene.

I've used propane to shrink bushings or whatever. You need liquid spraying out. Take the hose off your tiger torch/flame thrower. You need an old school valve on the propane bottle that lets liquid through. The new safety valves on bbq bottles won't work. Turn the bottle upside down so liquid propane sprays out from the hose. Direct it at your part. Wrap it in a rag or in the steel pale to contain the cooling. NO SMOKING!. Only do this outside! Wait.....DON't LISTEN TO ME!

Hi Team,

likely not much use in Central Oz but at the Dealer we used Liquid Nitrogen to freeze parts for easy assembly.

Maybe look at hiring a cryogenic flask/container.

Seems to be readily available but I have no idea of the costs for the liquid or flask hire.

A specialised truck used to come to the Dealer and supply and fill said flask when we had a job requiring such.

I guess this saves overheating parts and having them loose their temper/hardness necessary for long life.

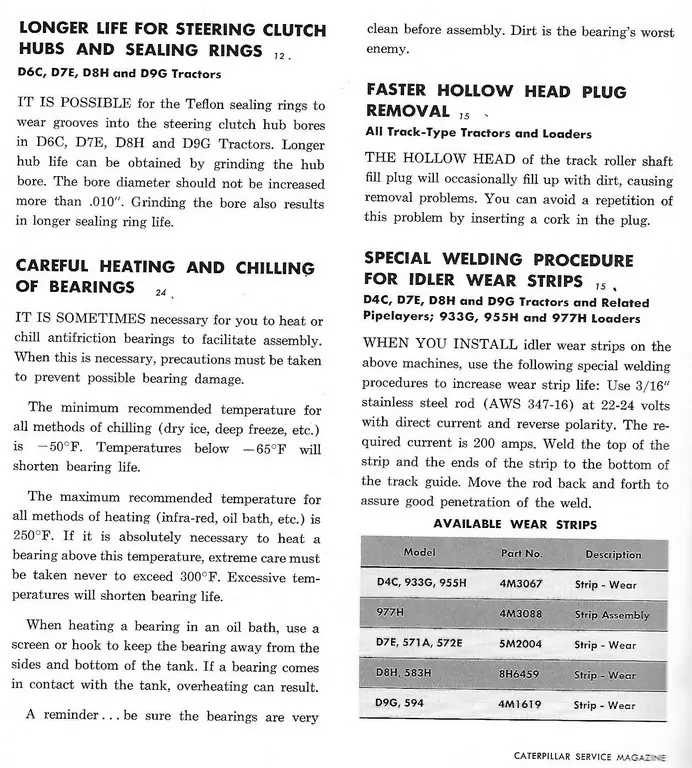

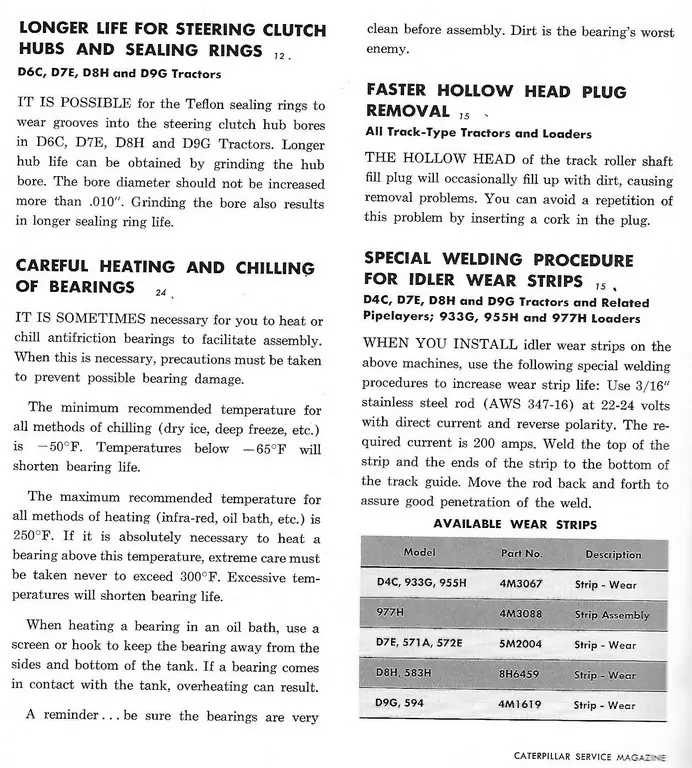

As a guide only, the scan below is what Cat have to say on rolling element bearings as regards Max--Min temperatures so as not to loose the designed bearing hardness etc.--no doubt track components can go a bit warmer but I would think that Red Hot would be too hot and temper would be affected--others with more knowledge may wish to comment.

https://engineering.stackexchange.com/questions/35/at-what-temperature-do-i-risk-altering-the-structure-of-steel

Quote from this site :-

The second consideration is the tempering temperature. This only applies to steels which have been heat treated, generally cutting tools, dies, springs and certain other very high strength/hardness parts. The tempering range can vary between 180 and 300 C or up to 600C for high speed steels. Heating above the tempering temperature will remember the steel and consequently soften it. this is usually only a concern for finished components although some types of stock are supplied hardened and tempered, typically high alloy tool steels.

Track components are fairly hard so I feel the info above carries some merit.

Just some rambling here and I stand to be corrected by more qualified persons.

Cheers,

Eddie B.

I know it's a bigger machine and a bigger track, but when we were putting a set of used tracks on our D7E, we found that borrowing a 16 pound sledge hammer made a huge difference vs the 10 pounder we normally use for everything. The old CAT Skinner we borrowed the sledge from also sent along a railroad spike hammer to drive pins. That was a very nice upgrade from the driver pin we had been using.

In this case since you're half way to getting them home, I think I would try either warming the links or chilling the bushing.

I've also used liquid propane but I always had it at hand with a LP fueled pickup truck. As mentioned, outdoors and NO sources of ignition, great if there's a breeze to keep the vapor cloud dispersed. I've gotten singed, so I'm a lot more aware of electrical sources of sparks than I was before that incident! A common source of liquid propane is a forklift tank. I expect it would be limited as to the volume/rate of flow available without tripping the excess flow preventer in the tank valve, but worth a try. Probably would want to have it squirting into a rag wrapped around the bushing to keep the liquid contained until it's vaporized and done the bulk of the cooling.

Liquid nitrogen or dry ice would be safer if you have a source. Artificial insemination companies and farms using frozen bull semen would be somewhat common sources of liquid nitrogen in many places. They maintain liquid nitrogen "dewars" I think they are properly called. Basically a large superinsulated tank filled with liquid nitrogen. The liquid boils off over time keeping the contents of the tank at -320 degrees Farenheight.

I recently had a skin lesion on my ear frozen at the doctor's in town. He told me he was driving 60 miles to a welding supply that still kept a bulk tank of liquid nitrogen to get his little tank refilled. I'm going to try to get the AI company rep that keeps our semen tanks filled to call on him in the future.

A business like that could likely supply/loan a tank that was no longer adequate to go long term (6-8 weeks) between refills but would be good for transporting a few gallons of liquid nitrogen to where it was needed. Farmers may have many thousands of $ worth of frozen semen in a storage tank so it must dependably hold enough liquid until the scheduled refill time. If it ever warms up much above the -320`F, the semen is ruined, so there is usually no tolerance for a tank that is not holding liquid as long as normal. One like that is retired and really can be used for only short term holds like this track job.

well looks like you got the cooling under control. as for heating go with acetylene and oxygen you want to do it fast a rose bud say 2" O.D. or a big cutting tip so you don't heat the pin up just the link. for the bigger size of tips you will need a big bottle at minimum one that 8-12 o.d. and 36-42" tall. not sure about your sizing down there . i used 1" nc nut welded on to a pin then used a simple hallow hyd ram and pipe the length of your pin to pull the pins out of a PC 300 excavator. a 1" nc nut and grade 8 all thread will holed 30 ton if welded good.

I always found getting the old pins out was easy, just gouged each end of the pin head to relieve the fit into the link and tap out with a small hammer. I don't know why every one likes to slog pins and try to save them, new pins are cheap and takes out some of the wear.

I know pin removal isn't your problem, to facilitate installation of pins and bushings I had a cut down track shoe bolted to the links, I cut the shoe so that it only just covered the links, did not protrude so that I could get a good go at the Bush or the pin. With both links held together you have a lot more solid base, it removes the flex and the hitting impact works much better.

Is your new bush the old parallel type or the newer type that has a slightly bigger waste than each end, I have had to grind down the later type bushes so that I could drive them in. The later larger wasted bushes are for SALT chains, I never worried about grinding down a bit as the rest of the bushes were already worn more than the ground bush. If it is a straight bush you could grind the middle section a small amount and the piece that protrudes out the other side for the counter bore, that way you only have to drive the first end through the first link, then it will just slide through to the point that both ends are engaging both links, you then have to put all your driving effort into pushing it in about an inch.

Make a dolly that has a pilot that fits inside the bush and a good shoulder to engage the bush and spread the load, beware frozen/cold hardened links can have pieces break off and fly around.

Best of luck, Wombat