Valve adjustment.....

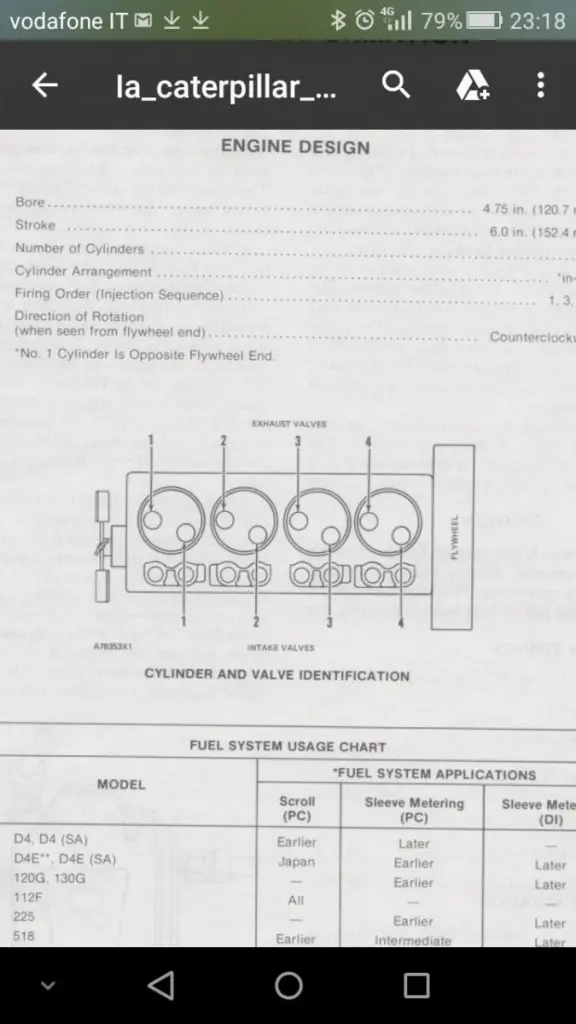

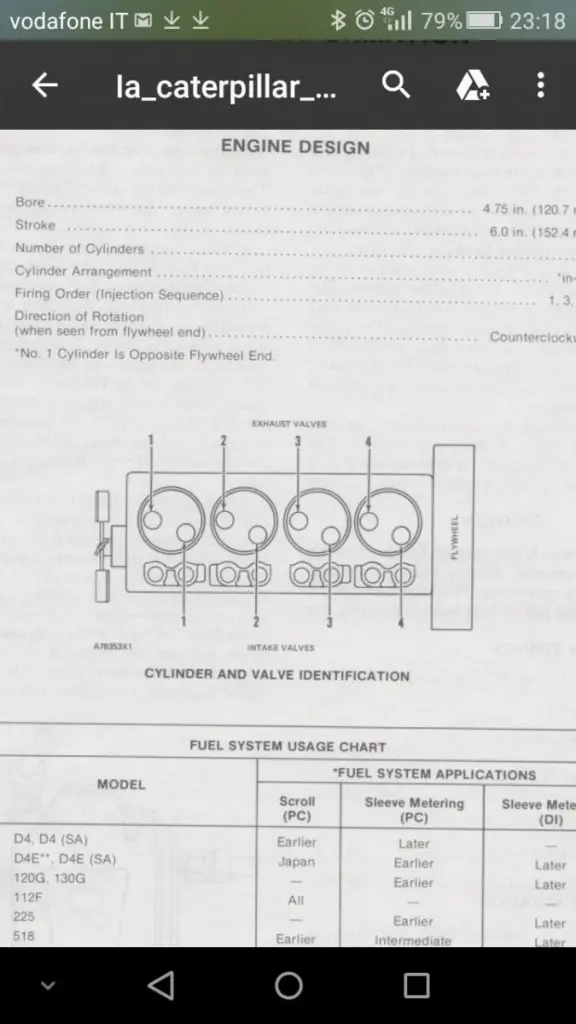

4-cyl, 1,3,4,2 firing order

Position #1 @ TDC

Adj. Intake #1 & 2, Exh #1 & 3

Rotate 360 deg. to #4 @ TDC

Adj Intake #4 & 3, Exh #4 & 2

Intake adjustment 0.015"

Exhaust adjustment 0.025"

Adjustments made with cold engine.

[quote="Old Magnet"]Valve adjustment.....

4-cyl, 1,3,4,2 firing order

Position #1 @ TDC

Adj. Intake #1 & 2, Exh #1 & 3

Rotate 360 deg. to #4 @ TDC

Adj Intake #4 & 3, Exh #4 & 2

Intake adjustment 0.015"

Exhaust adjustment 0.025"

Adjustments made with cold engine.[/quote]

hello I thank you.

I didn't understand.

on the flywheel I removed the cap 4h6112, I inserted the bolt.

Pistons 1 and 4 have risen to the top. the central pistons went down.

I reassembled the used head and the valves. In the piston 1 the valves were crushed, I unscrewed and brought them closed ... I did the same with the last piston.

I don't understand anything ... I'm doing old magnet wrong?

I'm afraid of making trouble

You have to follow the adjustment sequence. You can't adjust piston 1 and 4 at the same time.

Make sure you are at #1 piston top dead center not #4.

Installing the bolt at #1 TDC is where you start the adjustments.

When the #1 TDC position valve adjustments are done, rotate the crankshaft one full turn to where you could insert the bolt with #4 at TDC.

Complete the adjustments for the #4 TDC position and you are done.

If you don't understand get some help from someone who knows engines.

Don't guess if you don't know as severe engine damage can occur if you get it wrong.

Ok I'll try.

When I set the valves in the order you told me, they must be completely closed, right?

ps. piston dead center 1, and when it's completely up, right?

Piston 1 is the one near the flywheel, right?

I'll let you know tomorrow.

THANK YOU

[attachment=54162]IMG_20190530_232306.jpg[/attachment]

Is this the order of the pistons?

piston 1 opposite the flywheel

Evviva!!! you got it!

Yes, valve should be closed for adjustment.

#1 is at the front of the engine.

To check when done put #1 piston at TDC again. Both intake and exhaust should be closed.

Have any of the pump units been removed and replaced in the injection pump?

It's quite easy to reinstall them out of time with the rack. This results in strange sounds and lots of black smoke. If the manifold is installed already, the test for which one is wrong is to loosen each injection pipe connection in turn until the strange noise and smoke stops.